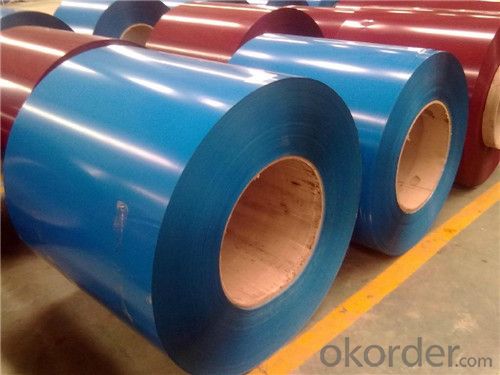

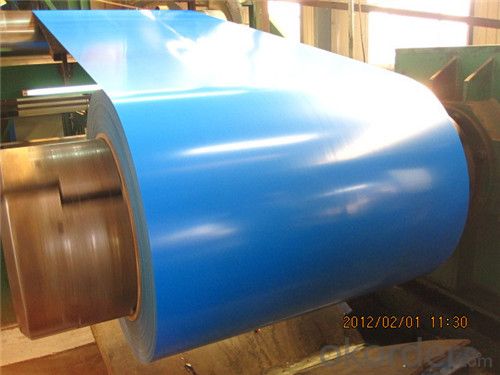

Z42 BMP Prepainted Rolled Steel Coil for Constructions

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Z42 BMP Prepainted Rolled Steel Coil for Construction

Description of Z42 BMP Prepainted Rolled Steel Coil for Construction

Galvanized steel is taken cold rolled steel as the base metal, after continuous hot dip galvanizing process, the product produced is an excellent resistance to atmospheric corrosion coating steel coil, as the steel gets coated in layers of zinc and rust won't attach this protective metal; Cold rolled plate by hot-dip galvanizing may extend the service life of 15-20 years.

For countless outdoor, marine, or industrial applications, galvanized steel is an essential fabrication component. Hot dip galvanized steel is used in applications where steel may be exposed to weather, but where stainless steel is too expensive.

Main Feature of Z42 BMP Prepainted Rolled Steel Coil for Construction

Galvanized steel sheet(include HDG and EG)

With the features of good corrosion resistance, the products are mainly used in automobile, home appliance, electronics, building and machinery manufacture industries, etc.

Precoated steel sheet

With the features of enviromental protection and good processablility, long lasting surface durability, rich in colors, the products are maily used in building, home appliance and furniture industries, etc.

Electrical steel sheet

Mainly used to manufacture generating equipment, locomotive, industrial motor and home appliance.

Applications of Z42 BMP PPGI Prepainted Rolled Steel Coil for Construction

A. Corrugated design makes it excellent waterproof performance

B. Materials as prepainted steel sheets, galvanized steel sheets, galvalume (Al-Zn coated sheets) are available to make corrugated sheet.

C.Those material are durable, anti-corrosion in bad weather for 20-30 years based on it's Zinc(Galvanized) coating or AZ (Galvalume) coating.

D. Different shape of the sheet make it suitable for any style of buildings.

E.Easy to install, no need special tools to fix the sheet.

F.Light weight due to high strength to weight ratio of steel. Light weight means easier handling lower shipping costs, easier installation

G. Different color is availbe base on the RAL Standard make your building more beautiful.

H. We will provide the best solutions if you don't have a exact idea of the specification you want for the steel sheet based on your weather conditions, engineering structure, construction budget and so on.

Specifications of Z42 BMP Prepainted Rolled Steel Coil for Construction

Product | Z42 BMP Prepainted Rolled Steel Coil for Construction |

Material Grade | SGCC / SGCH / DX51D+AZ, etc |

Thickness | 0.6-3.0mm |

Width | 500-1500mm |

Tolerance | Thickness: +/-0.02mm , Width:+/-2mm |

Zinc-coating | Z30-150g/m2 |

Technique | Raw material: Hot rolled steel coil --> Cold rolled_>hot dipped galvalume |

Surface | Dried, Chromated, Unoiled |

Spangle | Regular spangle , small spangle, zero spangle |

ID | 508MM 610MM |

Coil weight | 1-25MT |

Export package | Cardboard inner sleeves, Waterproof paper, galvanized steel covered and steel strip packed |

FAQ of Z42 BMP Prepainted Rolled Steel Coil for Construction

We have organized several common questions for our clients,may help you sincerely:

1. How Can I Visit There?

Our company is located in Tianjin City, China, near Beijing. You can fly to Tianjin Airport Directly. All our clients, from home or aboard, are warmly welcome to visit us!

2. How Can I Get Some Sample?

We are honored to offer you sample.

3. Why choose CNBM?

Our delivery time about 15-20days for standard sizes, if you have other requirements like hardness, quanity and width ,it is about 20-40days. But don't worry we also try our best for the delivery time ,because time longer and our cost is higher.

- Q: How are steel coils inspected for surface quality?

- Steel coils are inspected for surface quality through a visual examination process, where trained inspectors closely examine the surface of the coils for any defects or irregularities. This includes looking for scratches, dents, stains, or any other imperfections that may affect the quality of the steel. Additionally, advanced technologies such as automated scanning systems or cameras may also be used to detect and analyze any surface defects that are not easily visible to the naked eye.

- Q: How are steel coils used in the production of gutters and downspouts?

- Steel coils are used in the production of gutters and downspouts by being formed and shaped into the desired size and shape of the gutter or downspout. The coils are unwound and passed through a series of machines that bend, cut, and shape the steel into the necessary components. These components are then assembled and attached to create the final gutter or downspout, which provides effective drainage and protection for buildings.

- Q: My boyfriend says he has balls of steel.

- Easy to test. Put a magnet near them. If they attract, then they're made of steel. I'd be willing to bet I'd know what will happen, though! I know you can get metal hip replacements but .........

- Q: And by how much? I'm pretty sure that sterling silver is stronger, but I'm wondering if I could still use a metal stamp to stamp into something that's stainless steel - if it would be soft enough?

- Sterling is always best, but, in the 30's and 40's India also plated silver with brass overlay, believe it or not. They thought the look would be more attractive to tourist and more Indian traditional. Pieces marked India have been found to be 80% silver with brass overlay. Several times I have taken India marked pieces that looked brass to a metallurgist and found they are actually 80% silver with brass coatings. Like anything else, this is not always the case, either way, pieces marked and numbered will draw attention.

- Q: I need to say how a bottle opener is made, would it be made from steel and can this be coloured? How?

- Steel can be plated(Chrome),Blackened(Black Oxide),Powder coated(color of your choose).All of this is done to prevent rust.All of these aforementioned processes can be worn off through being used.I suggest polished Stainless steel.

- Q: I just got my Daewoo K2 in 5.56 and i know they are tough and reliable but how well will it fair with steel rounds. I know shooting brass is better for any gun but what kind of extra wear and tear would i be looking at with shooting steel. Also what about reloading steel. Is it recomended. I would not even be asking this but steel is far cheaper than brass ammo, and i need to save some money.

- You can't reload steel cases. I don't really know, but you just can't. If a mild steel case is harder than the chamber and bolt of your firearm, you should have got a better firearm.

- Q: steel can be used to do?

- Stainless steel can be used to (1) industrial use stainless steel (2) building decoration use stainless steel;(3) medical equipment (4) life with stainless steel tableware and the Jawaysteel is a great Chinese company, offer various kinds of stainless steel Maybe you can to their advice

- Q: I need to know a name of any site which provides information on Steel structures??

- steel structure- TC bolt to connect,SG shear wrench

- Q: What are the best types of steel for swords

- The okorder /

- Q: What are the common surface treatments for galvanized steel coils?

- Some common surface treatments for galvanized steel coils include passivation, chromate conversion coating, and painting. Passivation helps to enhance the corrosion resistance of the galvanized coating, while chromate conversion coating provides additional protection and improves adhesion for subsequent paint coatings. Painting can be done to enhance aesthetics or to provide additional corrosion protection, depending on the specific requirements of the application.

Send your message to us

Z42 BMP Prepainted Rolled Steel Coil for Constructions

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords