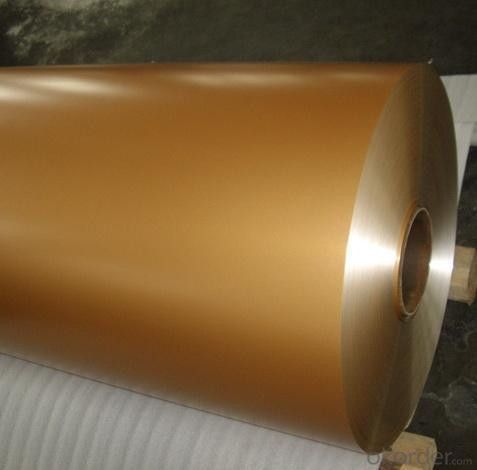

Z46 BMP Prepainted Rolled Steel Coil for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 66 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Z46 BMP Prepainted Rolled Steel Coil for Construction

Description of Z46 BMP Prepainted Rolled Steel Coil for Construction

1. Prepainted steel coil is coated with organic layer, which provides higher anti-corrosion property and a longer lifespan than that of galvanized or galvalume steel sheets.

2. The base metals for prepainted steel coil consist of cold rolled, HDGI Steel, electro-galvanized and hot-dip alu-zinc coated steel. The finish coats of prepainted steel coil can be classified into groups as follows: polyester, silicon modified polyesters, polyvinylidene fluoride, high-durability polyester, etc.

3. The production process has evolved from one-coating-and-one-baking to double-coating-and-double-baking, and even three-coating-and-three-baking.

4. The color of the prepainted steel coil has a very wide selection, like orange, cream-colored, dark sky blue, sea blue, bright red, brick red, ivory white, porcelain blue, etc.

5. The prepainted steel coils can also be classified into groups by their surface textures, namely regular prepainted sheets, embossed sheets and printed sheets.

Main Feature of Z46 BMP Prepainted Rolled Steel Coil for Construction

Uncoated CR steel sheet

With the features of in line with the international highest standards in demension and shape, excellent surface finish and properties, the products are mainly used in home appliance and automobile industries.

Galvanized steel sheet(include HDG and EG)

With the features of good corrosion resistance, the products are mainly used in automobile, home appliance, electronics, building and machinery manufacture industries, etc.

Precoated steel sheet

With the features of enviromental protection and good processablility, long lasting surface durability, rich in colors, the products are maily used in building, home appliance and furniture industries, etc.

Applications of Z46 BMP PPGI Prepainted Rolled Steel Coil for Construction

A. Corrugated design makes it excellent waterproof performance

B. Materials as prepainted steel sheets, galvanized steel sheets, galvalume (Al-Zn coated sheets) are available to make corrugated sheet.

C.Those material are durable, anti-corrosion in bad weather for 20-30 years based on it's Zinc(Galvanized) coating or AZ (Galvalume) coating.

D. Different shape of the sheet make it suitable for any style of buildings.

E.Easy to install, no need special tools to fix the sheet.

F.Light weight due to high strength to weight ratio of steel. Light weight means easier handling lower shipping costs, easier installation

G. Different color is availbe base on the RAL Standard make your building more beautiful.

H. We will provide the best solutions if you don't have a exact idea of the specification you want for the steel sheet based on your weather conditions, engineering structure, construction budget and so on.

Specifications of Z46 BMP Prepainted Rolled Steel Coil for Construction

Product | Z46 BMP Prepainted Rolled Steel Coil for Construction |

Material Grade | SGCC / SGCH / DX51D+AZ, etc |

Thickness | 0.6-3.0mm |

Width | 500-1500mm |

Tolerance | Thickness: +/-0.02mm , Width:+/-2mm |

Zinc-coating | Z30-150g/m2 |

Technique | Raw material: Hot rolled steel coil --> Cold rolled_>hot dipped galvalume |

Surface | Dried, Chromated, Unoiled |

Spangle | Regular spangle , small spangle, zero spangle |

ID | 508MM 610MM |

Coil weight | 1-25MT |

Export package | Cardboard inner sleeves, Waterproof paper, galvanized steel covered and steel strip packed |

FAQ of Z46 BMP Prepainted Rolled Steel Coil for Construction

We have organized several common questions for our clients,may help you sincerely:

1. How Can I Visit There?

Our company is located in Tianjin City, China, near Beijing. You can fly to Tianjin Airport Directly. All our clients, from home or aboard, are warmly welcome to visit us!

2. How Can I Get Some Sample?

We are honored to offer you sample.

3. Why choose CNBM?

Our delivery time about 15-20days for standard sizes, if you have other requirements like hardness, quanity and width ,it is about 20-40days. But don't worry we also try our best for the delivery time ,because time longer and our cost is higher.

- Q: Can steel coils be coated with anti-glare materials?

- Yes, steel coils can be coated with anti-glare materials. Coating steel coils with anti-glare materials helps to reduce or eliminate the reflection of light, improving visibility and reducing eye strain in various applications.

- Q: I want to start getting throwing knives and i was wondering what material is best for quality, but still cheap. I also saw some 440 stainless steel knives that i liked and wanted to know if the material was good

- Stainless Steel Throwing Knives

- Q: How are steel coils used in the manufacturing of agricultural equipment?

- Steel coils are used in the manufacturing of agricultural equipment as they serve as a raw material for various components such as frames, chassis, and structural supports. These coils are shaped, cut, and welded to form the necessary parts, providing strength, durability, and stability to the equipment.

- Q: I want to build an indoor riding arena, should I go for Steel ones.

- Though okorder /.. You can also have a look!!

- Q: Me and my cousin have been arguing about this. I said that superman is made out of steel, but he says that people just call him the man of steel because he's hard like steel. Does he have steel in his body?

- Superman okorder /

- Q: What are the pros and cons to selecting a graphite shaft sand wedge over steel shaft?

- I would assume that you want to carry at least two sand wedges in your bag - the modern set makeup today will have a 52 or 54 and a 58 or 60. Unless you are getting the matching wedges to a set of graphite irons , I would go with a steel shaft in sand wedges.

- Q: What are the common tests performed on steel coils for quality assurance?

- Steel coils undergo various tests to ensure their quality and compliance with industry standards and customer needs. Dimensional inspection is a prevalent test that measures the length, width, and thickness of the coils to verify their specified dimensions. Any deviations in dimensions can indicate potential quality issues. A thorough visual inspection is also conducted to identify defects and surface imperfections like scratches, dents, or rust. This examination is crucial to identify any visual flaws that may affect the coils' performance or appearance. Furthermore, mechanical tests are carried out to assess the strength and durability of the steel coils. Tensile tests measure the maximum force the steel can withstand before breaking, determining its tensile strength, yield strength, and elongation properties. Another commonly performed mechanical test is the hardness test, which determines the steel's resistance to indentation, indicating its strength and toughness. These tests are typically conducted using methods like Rockwell, Brinell, or Vickers. Corrosion resistance is also evaluated as a vital aspect of steel coil quality. Tests such as salt spray or humidity tests simulate harsh environmental conditions to assess the steel's ability to resist corrosion. Lastly, chemical composition analysis is performed to ensure that the steel coils contain the necessary elements in the correct proportions. This analysis verifies that the steel meets the required chemical properties, which significantly impact its performance and suitability for specific applications. In summary, these common quality assurance tests guarantee that steel coils meet industry standards, customer requirements, and are suitable for their intended use.

- Q: Can steel coils be customized according to specific requirements?

- Yes, steel coils can be customized according to specific requirements. Manufacturers can alter the dimensions, thickness, width, and other specifications of steel coils to meet the specific needs of customers.

- Q: How do steel coils contribute to sound insulation in buildings?

- Steel coils can contribute to sound insulation in buildings by absorbing and reducing sound vibrations. The coils act as barriers, preventing the transmission of sound waves and minimizing noise transfer between different areas of a building.

- Q: How are steel coils protected from mechanical damage?

- Steel coils are protected from mechanical damage through various methods such as using protective packaging materials like wooden crates or metal bands, applying plastic or paper interleaving, and utilizing specialized handling equipment during transportation and storage.

Send your message to us

Z46 BMP Prepainted Rolled Steel Coil for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 66 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords