WPC - Wood Plastic Composite Decking

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

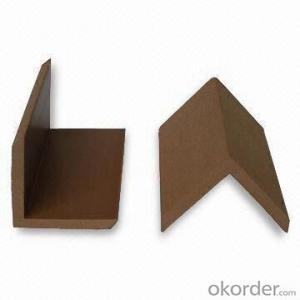

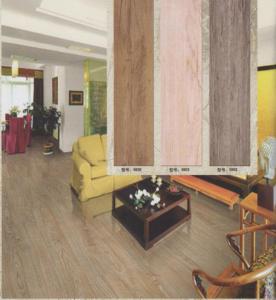

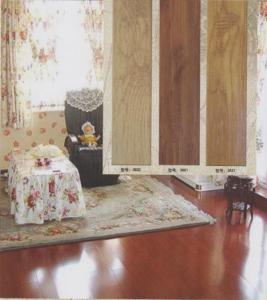

Wood-Plastic Composite (WPC) floor accessory is manufactured from a combination of plastic, natural fiber and some additives using special equipments. It mixes natural fiber and plastic perfectly to keep the natural impression of wood but with rich colors of plastic. It has gradually replaced wood and plastic, getting widely used in more and more fields.

For our wpc decking floor, there are many kinds of types, such as TW-K01(150 x 35 mm)TS-01(150 x 25mm), TH-07(140 x 30 mm), TS-A01(90 x 20mm),TH-16(133 x 24 mm, solid design) etc..

1. Material: 50% natural wood flour; 35%~40%HDPE, 10%~15% additives

2. Color: cedar, grey ,red pine, coffee, brown, nature wood etc.

3. Usage: outdoor, garden, summer house, villa, pool surrounds, exterior floor, seaside walk board etc.

4. Normal length: 5.4 meters/pc, can also be cut according to the requirement of customer.

5. Surface treating methods: Brushing, groove, sanding, embossing etc.

6. CE Approved

7. Advantages:

Keep the excellent character of plastic | Have the properties of wood | Produce fire-new WPC |

weatherproof | easy to cut, fix and glue | Can be recycled with 100% |

no crack, split, warp, or splinter | easy to tenon , drill and nail | No sting of wood |

High dimensional stability | Natural feeling0 | Requires less routine maintenance |

Resistance to insects | Resistance to UV | Is environmentally friendly |

easy to manufacture manifold profiles | innocuous | Multicolor, and needn't to painting |

- Q: outside our shower the floor has gotten wet some, and over time it has begun to wet the floor. now, the floor creaks some, and i think the particle board has gotten wet underneath. is there any way to dry this or help to remedy this process without actually replacing the floor? thanks

- Sorry, but if it’s particle board and it has gotten wet over time …..most likely it is ruined

- Q: Im trying to buy a house but it needs a new bathroom room. Im a tight budget with the down payment and everything. Does anyone know cheap bathroom floor ideas?

- Yep, carpet in the bathroom is gross. Vinyl tiles are the answer. Peel and stick if you don't mind them(I do), or ones from Home Depot that stick to themselves but not the floor. Or for really cheap, tear up the carpet and paint the floor. Sheet vinyl is good but unless you have some skill at fitting around corners and fixtures, don't try it.

- Q: Is this a necessity? Will laminate flooring become damaged over time if an underlayment isn't used? The previous owner of this home installed a wood floor in the living room without an underlayment so if I want to use a flat transition between this floor and the floor I'm going to put in the next room I'll have to leave it out to keep the floors level. If I chose a cheap foam underlayment how thick will it be? Thanks.

- The plastic coated foam underlayment is less than 1/16th of an inch thick. It should not cause a noticeable difference in the level of the floor between rooms. I wouldn't recommend leaving it out. It will increase the life of your floor.

- Q: I want to remove the laminate flooring and put tile in what tools do I need to use and how do you get the glue off

- It should be a floating floor. If it is glued together, then you can't save it. I like Don's answer, might be fun. Cut it up in manageable strips, have fun. If it is snap together, you might be able to save it for another project. You'd have to remove the baseboard or shoe, but you could save most of it. But if you don't care about saving it, go back to the circular saw. If the floor is the thin plywood tongue and grove with hardwood veneer of yesteryear, then you have quite a chore. Cut it up, and scrap, scrap, scrap. Some of that type was glued down. I'm sure it will very tough to remove by using a floor scraper and elbow grease. But that's only way I know of to remove the glue.

- Q: I am nearing completion of construction for my own new 2 story home. On the 2nd floor, I am planning to install a floating bamboo floor (5/8" stranded type) over gypcrete (lightweight concrete floor poured over radiant in-floor heat tubing. I think I can handle most everything, but I am not certain what the best option(s) is for running the floating floor into the staircase which goes down to the first floor. In the rest of the house, the edge of the floating floor will get covered by baseboard, but at the top step, there is no such option. Does anyone have suggestions as to the best way to deal with this? One more thing - it's tongue and groove and I was planning to glue the boards together. I already have the flooring and there are stairnosings I have with a groove on them which I was planning on assembling with the planks to cover the stairs too.

- Call or go to the place where you bought the floor and ask if they have anything to use where the floating floor will meet the step. They might have a piece of molding or something made just for that situation.

- Q: Why do price floors lead to surpluses? What is an example of a price floor?

- Price floor is a floor that you mop, for a price, typically in McDonalds restaurant. As a result of working there, you eat more food than you need, and you end up with surplus weight.

- Q: I have a 9x12 room in my basement, with a concrete floor. The rest of the basement has carpet on 1 1/2 inch sub floor. I would like to bring up the floor in the 9x12 room up 1 1/2 inches and tile. What is the best way to go about this? Vapor Barrier? Solid concrete floor clean and level. In basement. New England weather. Basement is always heated as most of it is finished. Plan on using 3/8" slate or granite tiles

- Slate and/or Granite can be layed directly over the concrete slab. If your floor is too cold to walk on, then consider installing a sub-floor. If you wish to raise the floor, there are leveling cements you can pour over the floor for this purpose. these leveling cements are not the easiest to work with. As an alternative, you can use the leveling cement about 3 or 4 feet from the existing finished floor to rais the floor gradually. Installing a subfloor on a concrete slab: Use redwood 1 X 3 or 1 X 4 16 inches apart (redwood has a natural preservative which reduces the chance of rotting.) Cover the redwood and with a continuous sheet of 6 mil plastic. Nail or screw your flooring to the redwood (1/4 inch shorter that the thickness if the redwood (3/4 inch) plus the flooring (5/8 inch)) This will make your new floor higher than the existing finished floor.

- Q: My church recently had our concrete floors stained and then sealed with 2 coats of urethane..I have tried cleaning and buffing with a neutral PH floor cleaner which left a film on the floor. I have a couple questions since I am in charge of caring for the floor1. How do I keep the floor clean and shiney without leaving water marks or soap film on the floor?2.How do I buff and shine the floor?3.How do I remove the scratches and scuff marks from the floor?

- Concrete Buffing

- Q: Home shop is a very good solid wood flooring the day before yesterday in a high-end supermarket to buy a bottle of maintenance oil, they sent home maintenance time.When the door after the maintenance is over, the floor stepped up began to click on the creak. Wicked Wuchuan Mody Is this what is going on? Should I should find this manufacturer to be held accountable? Question added: is a floor maintenance of essential oils is not my own to fight, is the manufacturers sent to the top of the workers do not know what?

- The best choice for floor oil is fine weather. Before you press the oil must first remove the floor surface of the garbage and dust, be sure to use wring the wipes to wipe, must wait for the floor completely dry before the oil, oil when the cloth to use the cloth to wipe the floor, so that the full penetration of wood into the wood The When playing oil in accordance with the direction of grain carefully applied, do not leak or uneven thickness, and pay special attention to the floor seams. And then use polished polished polished polished polished, the floor will appear more bright. The surface of the floor after oil is bright, easy to wear, and easy to clean. After playing the oil, the general need to dry about 3 hours. Because the floor wood linen is in liquid state before use, in the process of oil, the sperm penetrate into the floor, the surface has gradually become solid attached to the floor. So, when the floor is hit or waxed, the doors and windows should be open and keep well ventilated. [Wooden floor maintenance essential oil In the maintenance of wood flooring, if the following conditions: poor ventilation or indoor high humidity case, the oil contained inside the water will make the wood floor moisture and the degree of deformation ranging from varying degrees. ] Now hit the oil to keep the indoor humidity better!

- Q: need instructions for installing laminate flooring.

- Aren't they on the package?

Send your message to us

WPC - Wood Plastic Composite Decking

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches