Wood Plastic Composite Decking / WPC Board / wpc decking

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

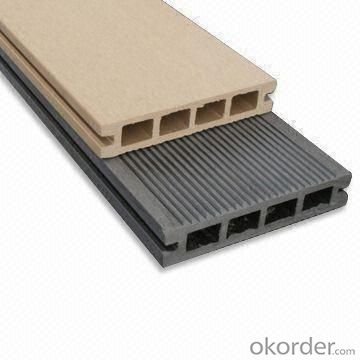

一. Structure of Wood Plastic Composite Decking / WPC Board / wpc decking Description

Item | WPC Project Decking-- China 10 Years Experience Composite Decking Suppliers |

Material | Wood Plastic Composite |

Color | Cedar, Coffee, Brown, Black, Dark gray, Light gray, Red wood, Red pine, Yellow, or adjusted to customer's requirement |

Surface | Groove, Wood Grain, Sanding |

Length | 2.2m/pc, 2.9m/pc, 5.4m/pc |

Application | Terrace, Garden, Lawn, Balcony, Corridor, Garage, Pool & SPA Surrounds, Boardwalk, Playground |

Packing | PE Film + WPC Pallet (length of 0-2.2m) or Wood Pallet (length>2.2m) optional |

Certificate: | CE, SGS, CMTL |

二.Main Features of Wood Plastic Composite Decking / WPC Board / wpc decking

Wood Plastic Composite Decking / WPC Board / wpc decking

1. Eco-friendly, fully recyclable.

2. With natural wood grain, color and texture, looks like nature wood.

3. Waterproofing, fireproofing, Mildew-resistant, anti-UV.

4. Less cracking, less warping.

5. No need painting, no glue.

6. Can be planed, nailed, drilled and cut to any wanted size.

7. Weather resistant, suitable from -40 to 60°C.

8. Easy to install, clean.

9. Low maintenance, durable, economic, long lifetime

10. Anti-slip, less cracking, less warping.

三.Wood Plastic Composite Decking / WPC Board / wpc decking Images

四.Wood Plastic Composite Decking / WPC Board / wpc decking Specification

Name | Wood Plastic Composite Decking / WPC Board / wpc decking |

Size | W*H=145*30 mm, CUSTOMIZED |

Length | 2200mm, 2800mm, 4000mm, Customized |

Material | Wood Powder, HDPE, Additives |

Surface Finishing | Sanding, Brushing, Wood grain |

Certification | CE, Reach, Intertek, SGS, ISO, FSC |

Range of Application | Outdoor Flooring, Garden, Balcony, Terrace, Pool Surrounds, Boardwalk, Playground… |

五.FAQ of Wood Plastic Composite Decking / WPC Board / wpc decking

. What kinds of wpc products do you have?

We have wpc decking in different size, fence series (only wpc material or connect with aluminum profiles, decking tile series.

. Is it difficult to install the wpc board?

No, it is easy to install. Using the tool which you use to install the real wood. Fix the board on the substructure with clips.

. Can you stick the label with our logo on the boards?

Yes, please provide the label drawing, we can stick the customized label on the board.

. What documents are available?

A full range documents, including products pictures, installation guide and relative certificates can be provided; Further more, customs declaration is provided. This is an one-stop service for you.

- Q: Wood floors and wood floors in the outdoor anticorrosion materials?

- Wood floor is a new type of environment-friendly wood plastic composite products, in the production process of medium and high density fiberboard in guaiacol, recycled plastic granulator made by adding wood plastic composites, then the extrusion group made of wood.

- Q: Wood floor plastic liner on the above or below

- Increase the comfort of the wood floor, play a mute, moisture-proof function, no matter which side does not affect these functions.

- Q: Today, just to shop on the EVA pad, the smell is very heavy to check it? What harm to the body

- Do not ignore the air circulation, ventilation for at least 4 hours a day, so that it can effectively eliminate harmful gases, is an effective way to prevent bacterial reproduction and increase oxygen. Floor should try not to composite floors, pure wood floors and wood floors best

- Q: What is the difference between plastic and rubber floors? Advantages and disadvantages?

- . Is a kind of popular in Europe and Asia, Japan and South Korea products, popular abroad, from the beginning of 80s to enter the China market, it has been widely accepted in the domestic large and medium-sized city, is widely used, such as indoor homes and hospitals, office buildings, factories, schools, public places, supermarkets, commercial and sports venues and other places. "The plastic floor" is a very broad term, originally "plastic floor" refers specifically to the polyurethane (PU) material production floor, floor laying, this motion is suitable for outdoor sports venues use field. Because of the release of harmful substances, are generally not used for indoor sports venues

- Q: Plastic floor and socket contact for a long time easy to catch fire

- The wood floor is a non-conductive insulator. How can it catch fire? Wires don't conduct electricity on wooden floors.

- Q: Thick floor leather household PVC floor paper waterproof plastic carpet anti-skid plastic floor glue how to install

- Floor leather referred to as civilian leather, poor quality of materials, can be used for a year, if the furniture and the like in the above pressure will be broken.Plastic floor glue construction (general) 10 per square meter, packaging materials of $40 per square meter, (Professional) construction of 13 yuan per square meter,

- Q: Plastic floor joints how to deal with?

- Hot melt welding: when the plastic floor laying is completed, the use of plastic floor materials and the corresponding special electrode, according to the type of material to adjust the temperature of hot welding.

- Q: Plastic floor paper how much a square

- Hello, Hello, the price of plastic floor may affect the price of the following reasons:

- Q: Have engaged in the PVC floor production or research work of predecessors, I am a college student in the existing fireproof problem research project called the PVC floor, check a lot of information without too much of the harvest hope that senior for guidance

- So there is no need to deliberately add flame retardants. Of course, if the flame retardant requirements are higher, it may be necessary to add a flame retardant or difficult to get into it

- Q: 3dMAX plastic flooring how to paste like tiles

- You may be compared to the glue and the tile of the house property, the tile is generally specular reflection, there are brick seam, high light blur basically no

Send your message to us

Wood Plastic Composite Decking / WPC Board / wpc decking

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords