Wood Plastic Composite Decking / WPC Board

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m

- Supply Capability:

- 20000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Wood Plastic Composite Decking Made in China

一.Product Description:

. With natural wood grain and looks like nature wood, less timber problems.

. Approx. 90% recycled materials, environmental friendly, saving forest resources.

. No paint, stain or oil required, low maintenance.

. Weather resistant, suitable from –40°C to 60 °C.

. Resistant to termite and insect attack, will not split, rot or warp.

. Easy to install and low labor cost.

. Cutting and drilling like timber.

. Span is 300~400mm.

. Six standard colors, standard length 2.2m or 3.6m, custom length available.

escriptions :

The characteristics of Wood generally had the problem of Waterproof and the serious concern to the environmental protection has been increasing day by day as well as it caused the Governments worldwide to stipulate the law to restrict to fell trees to reach the goal. To satisfy with the market's demand we utilized the characteristics of macromolecule to combine with the high technology of heavy pressure-micro foaming to produce an unique product with the invention and innovation of revolution.

Properties :

1. 100% recyclable product meets with the environmental protection without

adding any wood flour or sawdust.

2. 100% waterproof.

3. Suitable to be used for the activities indoor and outdoor.

4. The component with high quality features that the density is similar to the wood

(D:0.6~0.7 g/cm3) and light.

5. The processing is similar to the general timber, e.g.: shave, saw, trim, nail, drill,

wash and grind.

6. Strong rigidity and durability. (Similar to teak)

7. Thermal process is easily executed to be blended to have various shapes of the

materials.

二.Technical Data

Slip resistance:

Boards of Techwoodn according to ASTM D2394-05. This is the best ranking for bare-foot slip resistance.

Weathering resistance:

Boards of Techwoodn have very low moisture uptake.This is key for mold and mildew resistance.

UV resistance:

4000 hours accelerated Xenon-arc Exposure,the Boards turned slightly more clear and colored.

Abrasion resistance:

The resistance to abrasion is similar to oak.

Fungus resistance:

Whatever fungus the wood composite is exposed to,it is extremely durable.

Moreover,aging test does not affect this durability.

三. FAQ

. What kinds of wpcproducts do you have?

We have wpc decking in different size, fence series (only wpc material or connect with aluminum profiles, decking tile series.

. Is it difficult to install the wpc board?

No, it is easy to install. Using the tool which you use to install the real wood. Fix the board on the substructure with clips.

. Can you stick the label with our logo on the boards?

Yes, please provide the label drawing, we can stick the customized label on the board.

. What documents are available?

A full range documents, including products pictures, installation guide and relative certificates can be provided; Further more, customs declaration is provided. This is an one-stop service for you.

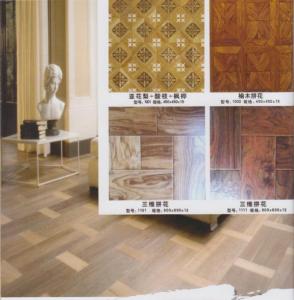

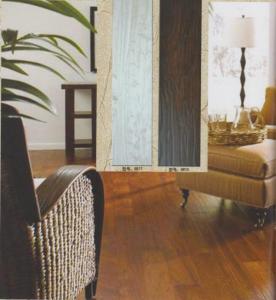

四. More picture for your reference

- Q:hotels skip 13th floor...some skip the fourth but most skip the 13th....i know....i just watch the movie 1408 and then i saw that they skipped a floor....i never knew it until i watched the movie..i am just so curious.....and i also noticed...they really skipped a floor

- they said that the number 13 is a devil's number that's why there are no 13th floor in the elevators in hotels. 13th floor is said to be the unlucky floor because many people experience ghost things another said that many people who stays on that floor can't go back home or something bad will happen...

- Q:I am laying a three part epoxy resin flooring to a factory floor. Any tips?????

- I don't know about this thing but I want to help you. So, I suggest you to visit given link to know more about epoxy flooring. This is originally suggested by my brother.

- Q:Stick to strengthen the floor how to paste, with what accessories? What kind of ground can be posted?

- Stick to strengthen the floor how to paste, with what accessories? What kind of ground can be posted?

- Q:What can be used to mop wax floors in-between waxes? My employees and I are having a hard time finding a cleaner that won't ruin the surface. For now, we are using just hot water and a mop but the water always leaves marks and doesn't seem to really do any. It just seems to make it dirtier. Any suggestions?

- get a bucket of clorox and a mop.... OOOORRR u can hire a proffessional to do ur job!!!

- Q:I am considering buying a home Illinois. Unfortunately my price range is small; however there is a home my girlfriend and I love. The floors are slanted because the foundation has sunk because it’s a 100 or more year old home. Is there a way to fix the floors by adding more plywood or something to the lower part of the floor?

- thats probably a big project......a carpenter would have to come in and raise your floor joist up by a jack and go from their.....its difficult to see exactly how big a problem you would have but a carpenter could tell you exactly how hard the job would be if he came out and looked it over............

- Q:80 * 80 tiles multiple

- Ordinary tiles of a box of three pieces of weight is 46 Gongchuan Fu pull off the burglary turtle Kawako Kok / box. Micropowder (slightly better) weight is 48 kg / box. The best (travertine and the like) Weight is 50-52 kg / box.

- Q:Pergo Flooring install question

- Yes you can Lenny...as long as the tile is stuck down tight.... Blessings

- Q:im building a new one level home to sell and putting laminate flooring(good quality) throughout with the exception of the 2 bathhrooms(ceramic). im just trying to figure out if it would be at all weird to have the same flooring throughout...everywhere? i mean its open concept great room and then 3 bedrooms down a short hall. I thought maybe too much of one thing? or would it look weirder to stop at the doorways of bedrooms and change to a different colorr of laminate flooring?

- I think both ways work,but I would change it only if you plan on doing something completely different such as carpeting, or a white laminate...otherwise why bother?

- Q:I am installing a bathroom but have been advised to only use wood, not tile or ceramic, flooring directly on top of the concrete because the tile will crack. What are my options?? The basement is poured if that makes a difference.

- Hmm... I'm just curious on how do you drain the basin, floor trap, WC or shower. Just in case, you are at basement, can the water drain out via gravity to outside ICs? If you need piping below, you might think twice to install a raised toilet floor rather than hacking the concrete floor. If you need to do this, you may go for a heavy duty cement board on floor joists wtih expoxy tiling finish or vinly flooring. Concrete is the best substrate for tiling but you need to waterproof the area before screeding/ tiling on top.

- Q:I just got my wood floors refinished about a year ago. But over time I noticed the my floors are dull and blotchy. Recently I have used "Bruce" hardwood floor cleaner and "Rejuvenate" which both claim to shine and not leave a residue. I have tried washing the floors with water but still can't get rid of it. Why are my floors not shiny anymore?

- You need to have your floors re-sanded and then varnished. That should have been done in the first place.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Wood Plastic Composite Decking / WPC Board

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m

- Supply Capability:

- 20000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products