Wood Plastic Composite Decking / WPC Board /

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 g/m²

- Supply Capability:

- 10000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

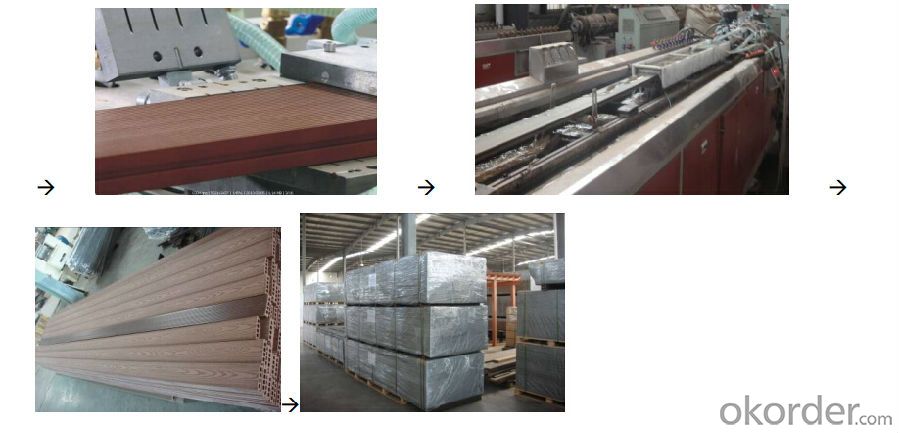

1> What is WPC?

WPC, simply for wood plastic composite.

Wood Plastic Composite is made from a unique combination of plant fiber and recycled plastic

according to high-tech formula.

It offers the best advantages of plastic and wood. The plastic shields the wood from moisture and

insect damage, and the wood protects the plastic from UV damage and gives you a natural feel.

It has characteristics of high strength and rigidity, acid and alkali resistance, corrosion resistant

and without formaldehyde, it is a real green environment protection building material.

2> What’s WPC used for?

WPC can be used for military equipment, urban utilities and landscaping, architecture,

gymnasiums, outdoor decking, fencing, pallets, indoor and outdoor decoration.

FAQ

3> Why choose WPC decking?

*Natural colour

*Slip resistant

*Resistance to water, rot and crack

*Guaranteed to last

*Low maintenance

*Beautiful and broad range of finish

4> What are the main kinds of WPC currently?

*WPC decking board

*DIY decking board

*WPC wall panel (wall cladding)

*Garden fence (railing)

*WPC outdoor furniture (gazebo, pavilion, outdoor desk&chair, dustbin, pet house…)

5> Ingredients of WPC?

30% HDPE+60% bamboo/wood fiber+10% Chemical additives.

6> How’s WPC made?

7> Specification of WPC?

A. Weatherability

suitable from -40° C to +60° C, UV resistance

B. Test Data

| Testing Item | Technical Requirements | Value of Test |

| Water Content % | ≤2 | 0.4 |

Rockwell Hardness (HRR) | ≥60 | 80 |

Thickness Swelling after Water Absorption (%) | ≤1 | 0.2 |

Screw Holding | Surface of board ≥1300 | 3870 |

| End of board ≥1200 | 3460 | |

Static Bending | ≥20 | 28 |

Bending Elastic | ≥1800 | 4610 |

Abrasion | ≤0.08 | 0.06 |

Hammer falling impact in low temperature, broken (pcs) | ≤1 | 1 |

State after Heating | No babbles, cracks and pockmarks | - |

Rate of Size Change with Heating (%) | ±2.5 | -0.38~-0.45 |

Report Number: 201107126

Type of sample: 90x25x820mm, Solid

C. Surface treatment

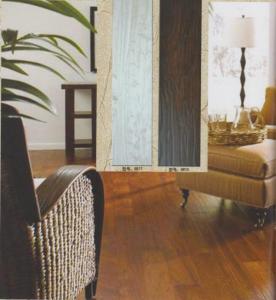

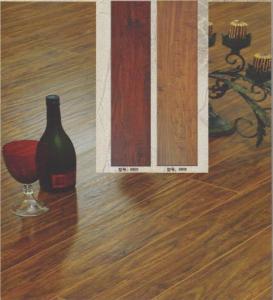

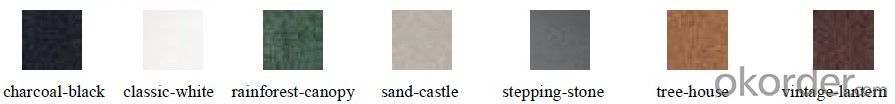

D. Main colors available:

charcoal-black; classic-white; rinforest-canopy;sand-castle; stepping-stone; tree-house; vintage-lantern .

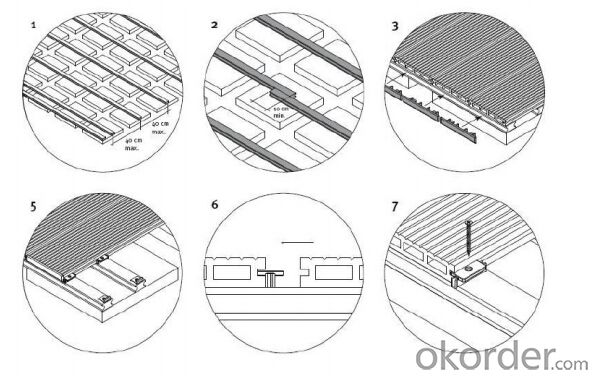

E. How to install

Company Information

8> About CNBM and It’s WPC products

China National Building Material Corporation (CNBM), long history since 1984 is one of the top

fortune 500 corporation and central enterprise with total assets of more than $20 billion and

120,000 staff.

Our unique advantages:

* Preferential payment terms

* Good and reasonable price

* Quality guarantee -- CNBM won't let a single small deal ruin our reputation and brand, so quality is

our lifetime.

* Professional team for CRM order processing & QA & logistics

*Global logistic database, originated from Dubai

- Q: I have a newly constructed basement (less than a year) which is being used for wine storage. Its too humid. I am adding ventilation and have treated the floor with a moisture barrier. Now I want to paint the floor.

- Firstly, a question - what do you mean by vapor barrier - if you mean a concrete sealer, I think you will need to remove that first. I have successfully used polyurethane floor paint available in a variety of colors from True Value Hardware Stores. Good luck!

- Q: The night of the old lazy old side of the lack of how to install the bitter fat bang is open in the house wash, there are pieces of the floor is always estimated that the water was pouring, a little muster, muster is not serious, but stepped up there will be a voice, consult experts How to deal with, can handle plus 20 points Thank you Question added: would also like to ask, if you find someone to repair, probably how much money, hey more

- Whether it is to strengthen or solid wood, had the edge of the ground line knocked, and then the edge of the floor a little dressing about.

- Q: It a good neighborhood. I really don't want to have to go up two flights of stairs everyday. I would be leaving with my bf so he could really do the grocery since he prefers the third floor.:)...i don't know how secure i would feel on the 1st floor........idk need advice.......

- The third floor will get you in really good shape. I had a fourth floor apartment once and got stuck in the elevator and took the stair thereafter. Had a bunch of friends over one Sunday to play cards and watch sports and up the stairs they came. Sure could tell who was out of shape and who wasn't. You will also get much better looking legs. First floor is not as safe plus you hear everyone over you walking around unless it is really insulated. I would chose the upper floor if it was the top floor just because of the noise plus you get a better view. Just grocery shop when your bf is home and able to run down and help haul stuff up. Never thought about fire tho. . .always be sure you have working smoke detectors whereever you live. That can save your life. It did mine.

- Q: I am about to redo the flooring in one of my bedrooms. I will be storing scuba equipment in this room and it will also be a computer room. What would be the best flooring to put in here. I don't think carpet , ceramic tile or hardwood floors would be a good choice because some of this equipment is heavy and could crack the ceramic tile and sometimes this gear may be a little bit wet so carpet is out .Any idea's?

- hardwood wouldnt be too bad as long as u dont leave excess amounts of water soaking over a long time causes the wood to rot... a little water will be okay

- Q: I'm looking into buying my first horse trailer. What types of floors are there? I've heard of wood floors, aluminum floors, and rumber floors. Are there any others? And what are the pros and cons of these floors. Which one would you choose?

- rubber mats can go over either wood, aluminium or steel floors. i reccomend aluminium because its much light than steel and lower maintence than wood. wood floors will need to be replaced eery 5-10 years where aluminium will not. make sure to clean under your mats, though once or twice a year. i also advise that you put down shavings over your rubber mats to soak up horses urine and prevent it from going under the mats (the amonia in urine eats away at any kind of flooring) and also to protect your mats- if you have a pawing horse they could rip a hole in the mats.

- Q: Explain how the Earth’s magnetic reversals provide evidence of sea floor spreading.Please help, just this one question.I go to TLHS

- There is a ridge down the center of the pacific. You can trace it up far to the north and it makes a hard right which is something to really think about. What caused this ridge is that the pacific floor is spreading apart about four inches a year. That space becomes filled with magma from below and as it surges up from below makes this underwater mountain range. That is part of plate tectonics. The process starts when a plate is being pulled apart and an example of that would be the Rift in Africa. The next step is that area fills up with water and and example of that would be the Red Sea. The ends of the rift usually have a V formation. Put that V upside down and it is visible with the Red Sea. As long as the tectonic forces pull the plate apart, this process continues and you have the Pacific Ocean. Should the forces change, it will stop and an example of that is the lower part of the Mississippi River. . .down where it is called Ol' Man River. The upper part of the Mississippi is from water drainage. At some point the pressure on the our plate stopped and the it just turned into our drainage system in the US. Makes you go back to that underwater mountain range and make you wonder what happen that those mountains at the end of the chain are going in a different direction and how does that relate to the Mississippi. Plate tectonic are really interesting to me. Having lived in Missouri for some time. There is a line across the southern part of the state and huge sink holes open up. I asked that question in geology and everyone shrugged their shoulders. But couldn't that be the V I talked about. I had a friend with a farm down there and it's on this invisible line. They took me over to their neighbors to see this large hole. Their barn and a great deal of acreage had just disappeared down this hole. Interesting stuff. . .hope this helps.

- Q: My floor looked great when I had it installed, but cleaning it is a pain. After cleaning the floor it has plenty of streaks and looks terrible.How can I prevent the streaks?

- White vinegar and water, dry after is recommended....all the others are not!

- Q: I see the general family are the bedroom floor, the other places shop tiles, our home more than 80 flat two rooms to prepare two sets of helium Fu Huang Bing Hao Feng ketone tied through the shop 800 tiles, okay? Especially health ah, after the match with the furniture ah, there are other aspects, and so on, thank you. More

- Yes ah, usually the bedroom floor is better, because the tiles, then cooler, we sometimes like the summer barefoot in the bedroom to walk, the floor is better point. But the living room, then the tiles are good, because we clean every day, but also water, so tiles are more water, easy to clean.

- Q: We have pergo wood laminate flooring and lots of shallow surface scratches on it. What can I use to make the floor look better?

- To fix a minor scratch in your laminate floor, you will need to purchase a laminate floor repair kit. You can find these at most hardware stores. Make sure to take a piece of flooring with you so you can match up the colors. Follow the directions on the package. Most laminate flooring manufacturers will offer their own repair kits also. These kits will have the right color wood putty (Colorfill is one brand) to fill in the gauges in your floor seamlessly.

- Q: To do a 1500 * 80 * 80 cm fish tank, the weight of the water after the installation of 1 ton, do not know whether the building floor can withstand more

- better not. According to the design specifications, most of the floor of the live load design value of 2-2.5kN / square meter, although the general will not be something that is not allowed someday you next to the fish tank and put a small and heavy objects on the dangerous trough More memorable tea remover. Suggestions on the floor above the beam should be no problem. So look at the drawings, find the location of the beam. Or corresponding to the location of the roof beam to find the location of the beam below, because the standard beam position are basically the same.

Send your message to us

Wood Plastic Composite Decking / WPC Board /

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 g/m²

- Supply Capability:

- 10000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches