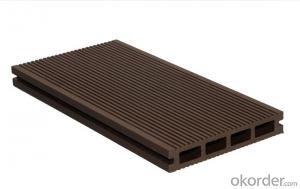

WPC decking / wood plastic composite deck board

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 2000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of Wood Plastic Composite Decking

The WPC decking is a new material, combine the nature look of a wood deck with the advantages of a weather-resistant, stable, easy to clean, and sturdy high-tech material and quite follow the trend of wood substitute.

Application of Wood Plastic Composite Decking

widely used for outdoor decking floor,Wall panel.railing,fence,bridge,dock,gloriette,gazebo,boardwalk,etc

Advantage of Wood Plastic Composite Decking

1. With the look of the natural wood but less timber problems, Approx. 90% recycled materials

2. Weather resistant, suitable from -40 to 60 °C

3. Resistant to termite and insect attack, will not split, rot or warp

4. Cuts and drill like timber

5. Requires no painting, no glue, low maintenance effort

6. Easy to install and clean

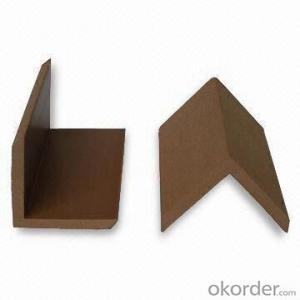

Packing of Wood Plastic Composite Decking

Packaging Detail | 112pcs per pallet, 16pallets per 20ft, 24 pallets per 40ft. pallet size:290x105x1375px |

Delivery Detail | 15 days after received the deposit |

Pictures of Wood Plastic Composite Decking

Specification of Wood Plastic Composite Decking

component | 30%HDPE+60%bamboo/wood fiber component+10%chemical additives |

Length | 2.2m, 2.9m, and 5.8m or customized |

Size | 140X20mm,150X25mm,145 X21mm,145 X25mm, etc |

Surface treament | original, sanded, brushed |

Color available | 5 regular colors for choice ( IPE, Walnut, gray stone, Cedar, Rosewood) and we can adjust the new color according to the order requirement |

FAQ

We have organized several common questions for our clients,may help you sincerely.

1. How about your company?

Our company is a world class manufacturer & supplier of Wood Plastic Composite and is one of the large-scale professional investment Wood Plastic Composite bases in China. Annually more than 1000 containers of Wood Plastic Composite bases are exported to markets in Europe, North America.

2. How to guarantee the quality of the products?

We can supply certificates, including ISO9001, ISO14001, CE, FSC Certificate, "REACH" Test Reports by SGS; Intertek Test Report by ASTM standard..etc.

3. How to install the WPC decking?

Installation tool: electric saw (desk type or portable),churn drill, electric portable drill and driver

Decking and accessories: 1.decking 2.joist 3.metal clip 4. plastic expansion screws 5.start clip 6.fascia

Installation step:

1. Fix the joist. 2. Decking installation. 3.Fascia installation

- Q: Solid wood flooring and composite flooring which is good

- There is no absolute good or bad points, solid wood flooring using natural wood to do raw materials, environmental protection, high grade, foot feel good, and visual effects. The surface is made of natural wood, no deformation, no cracking, simple pavement, surface wear resistance and non-slip flame retardant performance. My home is the Moganshan solid wood flooring, very good, no taste at all

- Q: How to deal with composite floor cracks

- The use of the floor for a long time, there will be damage, cracks, then how to repair the cracks in the floor? Do not worry, the floor cracks, the following methods can be used: with putty and paint mix well embedded cracks, can not bad for many years. Cut the old newspaper into debris, add alum and water, boil into a thick paste, and then use a knife to paste the paper into the cracks, after the dry is very strong. With cotton or broken sacks burn ash, and then stir with raw tung oil into a paste, embedded in the cracks in the floor. After the dry can be very strong. Buy "bakelite powder" with the dish Sheng, drip into the water and stir to the slurry, and then brush the cracks, a little spray into the water, fill in the bakelite pulp can usually be a night time bakelite pulp can be dry through the hard, Wood flooring can be trampled as usual.

- Q: Yesterday forgot to turn off the water, so the two rooms of the composite floor Geng Gong blunt blossom yellow fake riveting all bubble in the water, and now the surface of the water has been disposed of, but there are water underground floor, the Internet Some people say that there is no big problem to dry, and some people say that the floor should be set off to dry the shop again, really do not know what kind of practice better, please help out, give suggestions? Thank you! More

- If the floor gap is also into the water that is not saved, and can only install a new floor. Because you installed the floor is made of small water, the water will be inflated deformation. Has been soaked in the water that the board has been absorbent, and no way. It is recommended to use the next multi-layer solid wood flooring it, you can soak a good floor, aluminum oxide wear layer, super wear-resistant, you can also use boiling water, but also very environmentally friendly, that taste is not.

- Q: Did not hit the wax

- Now the wooden floor, almost no solid wood plate, the normal are some composite floor, so if the blister from the skin or drum package, it is already destroyed the internal structure of the floor, resulting in the floor was soaked inside the bubble , This situation is simply can not be restored, because the internal organization has been destroyed, it is impossible to restore the original. So there is only one solution to this problem, that is, to buy the same floor, which piece of a problem, to replace which piece, this relatively speaking, it is very easy.

- Q: Is the composite floor fading away?

- No, the composite floor is made of decorative paper, there is no fade this problem!

- Q: After the floor of my house is finished, the flooring company says it does not need waxing is compounded, is it like this?

- I have answered this question several times! The Choose to strengthen the composite floor, the main thing is the fancy of her environmental protection and wear, like the same tile tiles to save Li chewing pad wedge blind use, the word "skin". If the floor is really as bright as the solid wood flooring, unless the surface of the floor brush a layer of paint, but his wear resistance is gone, there will not be the so-called 8-10 years of quality assurance; 2, my Advice is not to wax, if the wax do not fight solid wax, if the fight, the consequences will be disastrous, just the beginning of the very beautiful, no 3 days, your floor light will be foggy, in the It is very troublesome to deal with the foggy surface of the floor. 3, to recommend you on the market there is a floor for the maintenance of the spices, the brand has a wife, etc., the benefits of this material is used after the floor pattern is more clear, three-dimensional effect is better, if you want to improve the floor Brightness, wait until your home floor with 3 years later, you will find the composite floor will be used with the more bright.

- Q: My family is preparing to decorate, is considering the floor or floor tiles, we intend to live with the room with the room is also a rough dwarfed gnome dumplings evil spear pave the floor, but a friend said my house east-west, sunny, afraid of the floor can not stand Alice Is it really like this? There is a large living room area, the floor is assembled. Easy to loose more

- can..........

- Q: Now the home of the composite floor ~ how much the general price ~ ~ ~ ~ ~ ~ ~ more

- Do not talk about a (formaldehyde) discoloration, no matter what the floor, the furniture contains formaldehyde gallon forged dawdle fist boxing, solid wood flooring, furniture does not represent environmental protection, it is important to see the quality, as long as the amount of formaldehyde in the standard Within the scope of environmental protection. The air also has a certain amount of formaldehyde, we can not breathe. Do not understand the words to buy the brand, the composite price should be more than 80, more than 200 solid wood, you know, under strict standards of production costs will not be low, the final price to see the individual affordability. In addition, solid wood flooring appearance is good, high grade, composite flooring economical and practical, good wear resistance, in the case of quality assurance, according to individual needs. From the environmental point of view, the composite floor is more economical and environmentally friendly, its raw materials are a few years old small trees, and solid wood flooring on the wood more demanding, the production process of waste. Overall, benevolent see benevolence, the wise see wisdom, I visited the floor because of the production workshop, know a little two, laughed.

- Q: My place where small, something more, had their own shop composite floor, do not know how to shop. Consult the knowledgeable master to help give pointers about, thank you! More

- Ready to hammer, and a board, each board to fight up when there will always be gaps, with a hammer pad with a knock on the board, the raft razed the drums can not directly knock on the floor, the floor will be knocked on the floor , Skirting line, then directly with glass glue it, a simple point

Send your message to us

WPC decking / wood plastic composite deck board

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 2000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords