Hot Sale Wide Board Oak Engineered Wooden Flooring

- Loading Port:

- Dalian Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1000 m² m²

- Supply Capability:

- 40*40GP m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery:

Packaging Detail: Pearl foam +Cartons (neutral or according to customer's requirement)+ Pallets

Delivery Detail: 30 days after received the deposit

Specifications of solid oak flooring:

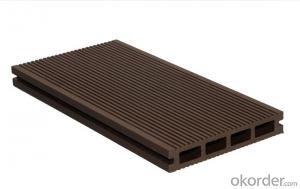

Hot sale wide board oak engineered wooden flooring/solid wooden flooring

Tongue and groove

UV lacquered

4 sides micro beveled

Hot sale wide board oak engineered wooden flooring/solid wooden flooring

1)Top veneer is oak, bottom material is plywood

2)Origin: China

3)Model: Multiply layer engineered wooden flooring

4)Size (mm):

910x125x12/0.6mm

910x125x15/0.6mm

910x125x15/2mm

910x125x15/3mm

5)Color:As customer's requirment

6)Grade: A or AB

7)Moisture content: 8%-12%

8)Joints: T & G , 4 sides are micro bevel 0.5-0.8mm

9)Surface finish: Gloss or Matt finished. Highly anti-scratched and abrasion resistance, UV lacquer coating; total 9 layers coating

10)Packing: neutral or according to customer's requirement

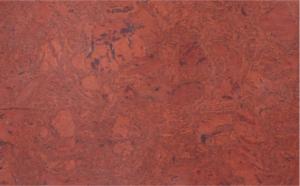

white oak engineered flooring description:

1. PPG glue or OSMO natural oil

2. Top layer: 0.6mm-6.0mm can make

3. Natural color or customized color

4. Surface treatment: Smooth or wire-brushed or hand-scraped

5. Tongue& Grove

- Q: What kind of composite flooring is good?

- Now the use of composite floor decoration room has been very wide, but the different brands of composite flooring in the performance indicators there is a big difference I personally think that the best choice on the market relatively large brand, so the quality and after-sales service Satirical kettle is better, such as Sao Paulo, icons, nature and so on!

- Q: How to deal with composite floor cracks

- The use of the floor for a long time, there will be damage, cracks, then how to repair the cracks in the floor? Do not worry, the floor cracks, the following methods can be used: with putty and paint mix well embedded cracks, can not bad for many years. Cut the old newspaper into debris, add alum and water, boil into a thick paste, and then use a knife to paste the paper into the cracks, after the dry is very strong. With cotton or broken sacks burn ash, and then stir with raw tung oil into a paste, embedded in the cracks in the floor. After the dry can be very strong. Buy "bakelite powder" with the dish Sheng, drip into the water and stir to the slurry, and then brush the cracks, a little spray into the water, fill in the bakelite pulp can usually be a night time bakelite pulp can be dry through the hard, Wood flooring can be trampled as usual.

- Q: It is good or seamless for the elephant floor

- Seamless good pick up, there are cracks look dirty, all the black stripes, will breed bacteria. Recommendations or choose a seamless, high-end, a sense of the whole.

- Q: Composite floor water from the package how to deal with

- First of all, the first time of course, to the water on the floor quickly dry, to prevent the spread of water. Can also take the water in the water floor of the splash gap in the water sucked away the water vapor, or take the dryer with cold air dry. Second, if the water after the floor so that a small area of ??the seams from the Alice, you can use heavy pressure to pressure in the above, after a period of time after the wooden floor will return to normal. If after a period of time, the seam was drums down, but with the floor before the difference is too far, you can try to wax the floor, waxing after the bubble floor will be almost the same as the original. If the wax after the color of the floor, the shape and the original or a great difference, it is only partial replacement of the floor. Again, if there is a large area of ??the phenomenon of soaking water, should be promptly to inform the floor after-sales service. If it is solid wood flooring, as far as possible to keep the floor is not deformed in the case of the floor carefully pry up, according to the well-type superposition placed in the ventilation at the dry, with its weight produced by the deformation to prevent the occurrence of deformation, under normal circumstances for the quality Good solid wood flooring can be used again. If it is to strengthen the wood floor, quickly remove the floor of the baseboard, exposing the expansion joints, by the expansion of the water vapor will be distributed, according to the size of different seepage, dry up usually takes about three to ten days, generally strengthen the large area of ??wood flooring bubble The water is likely to be used again.

- Q: Why is it better to use solid wood flooring?

- Why is it better to use solid wood flooring?

- Q: My home is warm, has been heating, the composite floor was blisters how to do

- To warm if the leak ~ repaired in the shop ~ ~ ~

- Q: I would like to shop composite floor, but very worried about the use of its life in the village of law box Tanzania stumbling leopards call, the general floor operators say that can use 15 years, I would like to ask the knowledgeable, in the end can be used for many years ah more

- The number of years to see the number of wear and tear, and the service life is proportional to the general 6000 to use the family 15 to 20 years without problems, public places 3-5 years .4500 turn home in 10-15 years. Of course, mainly look at your use Do not use a lot of water mop to drag. Do not pour in the above. Main attention to the bathroom door, kitchen door. Living room, easy to contact with the water place

- Q: How to remove the composite floor stains

- Composite floor surface is a layer of aluminum oxide, and acid reaction, and no way to change it

- Q: How to strengthen the composite floor?

- The first step before the installation of the door can check whether the opening freely, if not, you can go to the bottom of the door to a certain thickness, and then a layer of PVC on the ground floor film to play a better sound insulation, moisture effect. Note that the cushion laying method is at right angles to the floor. The second step in the corner of the first board placed the location of the first board, tongue and groove on the wall, with a wooden wedge leaving 10mm expansion joints. The third step by the wall of the line to install the last board, take a whole board, and the former tenon relative to the parallel placed on the wall side to stay 10mm crossed under the saw, installed to the end of the line, if the remaining sheet length 40cm, Can be used for the next line first. The fourth step from the beginning of the second line should be evenly coated with the floor of the special glue (the first line does not glue), when the board is loaded, with a wet cloth or plastic scraper in time to remove the glue removed. The fifth step with a hammer and wood last to gently knock down the floor cutting plant Cui Chen Chao board coupons timid. Step 6 After the first two lines, in a timely manner with a rope or ruler calibration. The seventh step to the last line, take a piece of the whole board, on the installed floor, up and down alignment, and then take another floor, on the board, one end of the wall, and then crossed, and along the line saw (Note: need to set aside 10mm expansion joints), that is, the required width of the floor. Step 8 to the last line of the board, the first put the last block, with special fasteners will be squeezed into the floor, the installation finished, to be 2 hours after the withdrawal of wood last. The first step in the installation of the floor if the pipe out of the need to open holes in the floor, the diameter of at least 10cmm larger than the diameter, saw the surface should be 45 degrees with the board angle.

- Q: What is the difference between solid wood flooring, laminate flooring and laminate flooring? The

- Is aluminum oxide is not a trioxide to see where you are in the excerpts if it is geothermal, then do not shop solid wood solid wood flooring on it

1. Manufacturer Overview

| Location | Shanghai, China |

| Year Established | 2002 |

| Annual Output Value | Above US$ 24 Million |

| Main Markets | Europe; North America; |

| Company Certifications | ISO 9001:2008 ;IS01400:2004 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 80% - 90% |

| No.of Employees in Trade Department | 700 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | Above 30,000 square meters |

| No. of Production Lines | Above 4 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Average |

Send your message to us

Hot Sale Wide Board Oak Engineered Wooden Flooring

- Loading Port:

- Dalian Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1000 m² m²

- Supply Capability:

- 40*40GP m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords