Wpc Flooring,marble flooring border designs

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

wpc flooring,marble flooring border designs

一.Product Description:

.

Low flame spread / High slip resistance / No sting of wood / Contains no toxic chemicals or preservatives / Environmental friendly / Can be recycled with 100%

• High Strength

Outstanding screw and nail retention / High impact resistance / Great Compressive-tensile-shear strength / Modulus of elasticity: 20% greater than PVC

• Good appearance & nice touch

Natural feel & wood touch / Broad range of finishes and appearance, Multicolor, and needn't to painting

• Longevity

Its lifespan at least 10-15 years in the outdoor weather condition

• Install & Maintain easily

Easy to produce and easily fabricate / Easy to cut, fix and glue; Easy to tenon, drill and nail / Require less routine maintenance / No need staining & water Sealant

Competitive Price

• Using most advanced machinery to increase the output and reduce the costs.

Strong technical support from famous institute of high polymer to guarantee the best quality as well as cost saving.

• Neighboring one of the biggest wood/ bamboo processing industry region and having a special purchase channel of the raw materials (Plastic and wood/bamboo fiber)

• As a high technology and environmental-friendly enterprise, supports form the government such as reduction and exemption of tax rate are available.

escriptions :

The characteristics of Wood generally had the problem of Waterproof and the serious concern to the environmental protection has been increasing day by day as well as it caused the Governments worldwide to stipulate the law to restrict to fell trees to reach the goal. To satisfy with the market's demand we utilized the characteristics of macromolecule to combine with the high technology of heavy pressure-micro foaming to produce an unique product with the invention and innovation of revolution. We call this new product " CELLwood®".

Properties :

1. 100% recyclable product meets with the environmental protection without

adding any wood flour or sawdust.

2. 100% waterproof.

3. Suitable to be used for the activities indoor and outdoor.

4. The component with high quality features that the density is similar to the wood

(D:0.6~0.7 g/cm3) and light.

5. The processing is similar to the general timber, e.g.: shave, saw, trim, nail, drill,

wash and grind.

6. Strong rigidity and durability. (Similar to teak)

7. Thermal process is easily executed to be blended to have various shapes of the

materials.

二.Technical Data

Slip resistance:

Boards of Techwoodn according to ASTM D2394-05. This is the best ranking for bare-foot slip resistance.

Weathering resistance:

Boards of Techwoodn have very low moisture uptake.This is key for mold and mildew resistance.

UV resistance:

4000 hours accelerated Xenon-arc Exposure,the Boards turned slightly more clear and colored.

Abrasion resistance:

The resistance to abrasion is similar to oak.

Fungus resistance:

Whatever fungus the wood composite is exposed to,it is extremely durable.

Moreover,aging test does not affect this durability.

三. FAQ

. What kinds of wpcproducts do you have?

We have wpc decking in different size, fence series (only wpc material or connect with aluminum profiles, decking tile series.

. Is it difficult to install the wpc board?

No, it is easy to install. Using the tool which you use to install the real wood. Fix the board on the substructure with clips.

. Can you stick the label with our logo on the boards?

Yes, please provide the label drawing, we can stick the customized label on the board.

. What documents are available?

A full range documents, including products pictures, installation guide and relative certificates can be provided; Further more, customs declaration is provided. This is an one-stop service for you.

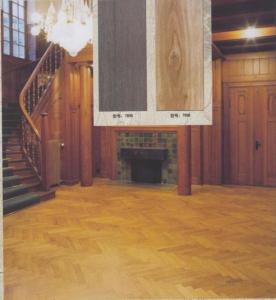

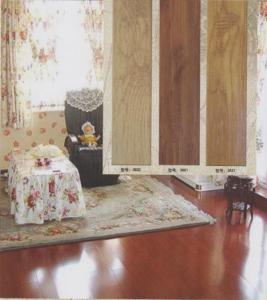

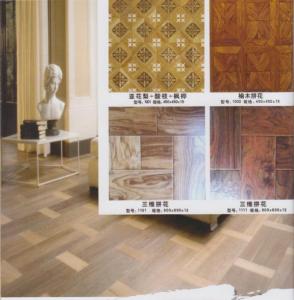

四. More picture for your reference

- Q: My mom installed peel n stick (DIY) tile on top of linoleum flooring. About a year later, she wants the job done right, so she is trying to pull the tiles up to install snap together wood flooring down. The problem is that now the old linoleum is too sticky to walk on. My question is how do I get the stickyness off of the linoleum and has anyone had any problems with the snap together wood flooring? Thanks in advance, God bless you all!

- If you mean the laminate wood, then any water problems can make it buckle. (For example, if dishwasher or plumbing causes a flood). Otherwise, the laminate wood should be fine. Clean: ? cup white vinegar in a gallon of water. Use damp towel (wring out excess water) to dip into solution to wipe floor, dry floor if needed. Wet mops may bring too much moisture to the floor. Floor can warp, if soaked.

- Q: Hi im trying to renovate my bathroom ,but im trying not to put that 1/4 inch cement floor to put the tile on cause its going to be biger than the living room floor is there anything else i can use that can be smaller than 1/4 inch floor board.i know theres like a thin membrain like paper or something ...please help

- Our tile is on plywood, which is screwed into the sub-floor.. and I know that comes in different heights. I dont think you need cement board for the floor ...just for around the bathtub and/or shower area.

- Q: I have laminate floors and someone told me to use swifter wet jet but it kind of leaves streaks so I would like something that leaves my floors nice and shiny. Any suggestions?

- I use Method (from Target) or Pledge floor cleaner (in the blue bottle). No streaks, and it looks awesome

- Q: We are trying to repair the kitchen floor in our new house. When we pulled up the linoleum rug (which covered only half the floor), we discovered there was tile below. My husband busted up part of the tile to see if the floor under it matched the hardwood in the rest of the house (including the other half of the kitchen). Apparently the tiles were placed on top of a layer of plaster. There is a wooden floor/subfloor below the plaster but when the tiles and plaster are removed, it leaves the floor uneven with the hardwood by almost an inch. We were going to put down plywood to even the floor and put the new flooring (laminate tiles) on top of that but after checking prices, that's not really feasible for us on our budget. Does anyone have any cheaper solutions?

- the only lasting way to do it is 1/2' plywood in 2 layers laid out so the seams don't line up. remodeling is EXPENSIVE trust me i know. you'll just have to live with it until you can afford to do it right.

- Q: Is dance flooring that plastic floor stuff, linoleum??Is it the same thing, or something else?Because I want to buy some cheap floor that is suitable for dancing on, maybe even the same as the ones they have in dance studios.Do you know:a) What dance floor is?b) Can you buy it cheap?c) Is there any flooring similar?d) Where can you buy them from?Thank you xx

- Linoleum would work for a while but won't last long on a dance floor. Most dance floors are hardwood, seamless tile or vinyl sheathing and none of it is cheap. Building supply stores would have whatever you decide on or could order it for you.

- Q: could u build a stair case on top of the floor without messing the floor up?

- Not a smart idea. The whole idea of a floating floor (another term for glueless laminate) is that the floor moves as it expands and contracts with temperature changes. That's why you have to leave a quarter inch gap around the parimeter when you lay the floor. Fastening anything permanent to the floor will limit that movement and eventually cause the floor to buckle. Always best to do it right the first time instead of cutting corners. Happy staircase building, I don't envy you!

- Q: How the floor is painted

- Hello there! The first floor of the machine polished, brush again thoroughly primer, polished and then thin brush again after the primer, adjust the color close to the floor color of the putty to fill the seam, and so dry polished clean, and then you can brush the finish, the general brush 2 at the end of 4 on it. for reference only

- Q: The whole second floor (approximately 800 sq. Ft) will have the laminate floors, with exception of the bathrooms.

- What's wrong with or your concerns with using transitions? The house will look weird if it looks like one continuous room, especially if you have doorways with doors. Plus if anything goes wrong it will be easier to fix with the breaks in the flooring.

- Q: Hey,I get ready to renovate the floor in the house, I learned ceramic floor tiles are available in colors that suit many decors. Because ceramic tiles are so long lasting, yet I get tired of the original color but not want to go to the expense of replacing the tiles. That's a good time to think about ways to decorate floor tiles to spruce them up and give them new life. How do I need to cope with the redecoration with the ceramic floor tile?

- You okorder , but it's not advisable to paint any tiles in rooms that have floors that are frequently wet, such as kitchens and bathrooms. Floor tile paint holds up well in other rooms.Clean the floor well with a detergent that removes any accumulated grease and oil. Rinse the floor well and allow it to dry. Urethane paints are a good choice because they adhere to the surface of the floor like glue. Use a roller to paint large areas. Choose one with a low nap to reduce air bubbles in the paint.

- Q: We want to tear out our carpet and lay down tile or linoleum. Are there any companies in Central Oregon that can install one of those? Also, which one is usually cheaper & which one would you recommend? Thx

- Any flooring company can do these things. Its as basic as it gets..Just look in the local yellow pages under flooring. Generally speaking your laminate flooring will be the cheapest to do. But installation methods needed and quality of the products you choose can be a factor. Any questions you can e mail me through my avatar. GL

Send your message to us

Wpc Flooring,marble flooring border designs

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords