Tapered Roller Bearing Manufacturer China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Descripcion

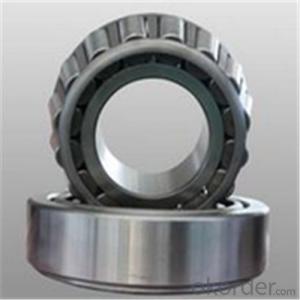

Single-Row Tapered Roller Bearings

The most basic and widely used tapered bearing, the single-row type consists of the cone assembly and the cup. It is usually fitted as one of an opposing pair. During equipment assembly, single-row bearings can be set to the required clearance (endplay) or preload condition to optimize performance.

Double-Row Tapered Roller Bearings

Double- or two-row tapered roller bearings feature double cups and two single cones. They are available in a variety of configurations for general industrial and automotive applications.

Four-Row Tapered Roller Bearings

Four-row bearings provide maximum capacity in minimum space, combining the inherent high-load, radial/thrust capacity and direct/indirect mounting variables of tapered roller bearings.

Their main application is on the roll necks of rolling mill equipment. All four-row bearings are supplied as pre-set matched assemblies with all components identified to ensure correct installation sequence.

Tapered roller bearings (TRBs) utilize rolling elements that are shaped like a truncated cone , and are constructed so that all tapered surfaces converge at a common apex point on the bearing centerline to yield true rolling motion. Tapered roller bearings are generally used in lower speed, high load applications and are capable of absorbing radial and/or axial loads. The internal angles may be designed to tailor the bearing to the loading demands of a specific application. Tapered roller bearings are a separable two-piece design (cup and cone) ; which, allows the end-use to optimize the internal clearance (and life) for each application when the bearing is mounted. PEER primarily manufactures single row (TS), sealed single row (LA), and matched set tapered roller bearings.

F&Q

Q:How long es cycle of bearing life?

A:According to international standards, at least a year and a half , up tu 2 years

Q:How to maintenance bearing

A:Add to lubricantes on time

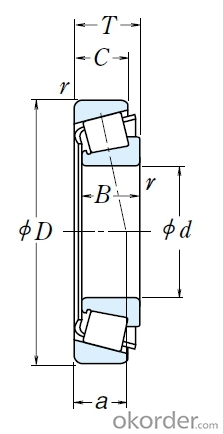

Q:Have diagram for bearing

A:The small one no have, large bearings will provide diagram

- Q: Why is the cage of tapered roller bearings loose?

- It is loose, the outer frame of the bearing cone is removable, as long as it is easy to install and add lubricant. You can come up with the relevant standards, must belong to the bearing standard parts, as long as you meet the standard requirements of the bearing can be spread!

- Q: How does the roller of tapered roller bearings fit in?

- Tapered roller bearings are made up of outer rings, inner rings, rollers, and cages. The outer ring is a single body, and the inner ring, roller and cage are assembled together. They are called inner components. Tapered roller bearings belong to separable bearings, and when installed, the two components (inner and outer rings) can be fitted together.

- Q: Tapered roller bearings 32010x, two matching, how to install?

- Suitable for heavy load and impact load. In addition to single row bearings, tapered roller bearings include double row bearings, pairs of double bearings and four row bearings. The taper roller bearing holder usually adopts a punch holder.

- Q: Tapered roller bearing: Bearing expert why burned or locked

- 2, the bearing seat hole size deviation is too small or the size of the shaft deviation is too large, extrusion bearing ring deformation, make the clearance smaller. To burn locking phenomenon.3, bearing outer diameter and bearing seat hole, or between the bearing bore and the surface of the shaft between the foreign body, such as iron filings, burr, sand, cotton and so on. Will also squeeze bearing deformation, so that smaller clearance. To burn locking phenomenon.Bearing burnt lock. The cause of the accident can be analyzed according to the burning degree of the inner shell, the outer shell and the roller1. The inner shell burns most severely, the roller slightly lighter, and the outer shell almost does not change. After excluding the reasons for the nonstandard size of the inner bearing housing, the following judgment can be made.

- Q: you master good! Ask a question about the use of tapered roller bearings: a mechanism using a double row tapered roller bearings, but did not buy this model, can use two single row tapered roller bearing together instead of double row?

- Not so simple, please consider the following: 1, clearance of double row bearings generally have clearance design, and no single, you need to set in the middle of every lap, with good clearance, clearance or big or small, or no clearance, you miserable;

- Q: Tapered roller bearings. Are the rollers tapered?

- The frustum of the cone can be seen as a right angled trapezoid revolving around the right angle, and the top is a circle. Can also be seen on top of the tip is tapered off, the tapered roller head is not a round face

- Q: Can tapered roller bearings be installed in a vertical direction? In a vertical direction rather than in a horizontal direction..

- Whether horizontal mounting or vertical installation, the axial direction is axial and radial is radial

- Q: What does "tapered roller bearing" suffix "A" mean?

- Tapered roller bearing suffix AA - angular contact ball bearings with a contact angle of 30 degreesA5 - angular contact ball bearings with a contact angle of 25 degrees

- Q: There are many kinds of tapered roller bearings, because of work requirements, test the external size is qualified, I want to make a test, to test the bearing is qualified, mainly inside and outside diameter and inside and outside the ring height tolerances, diameter ranging from 50mm--80mm, score less, look forward to your help, I thank you there are 322163311532215 main bearings, 313113002

- This is not easy yet. Do you think it's possible to make a standard check instrument yourself?!

- Q: that is to say, the taper head is the face and the back is the back

- The bearings do not have to distinguish between the front and back, and there is no positive and negative said, only in accordance with your actual use to identify the installation direction.

Send your message to us

Tapered Roller Bearing Manufacturer China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords