Angular Contact Ball Bearing Manufacturer China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

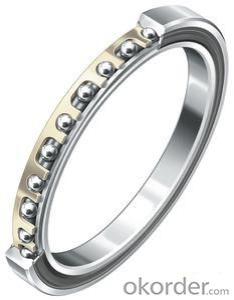

Angular Contact Ball Bearing

Description:

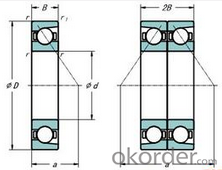

1,Single row and combined angular contact ball bearing

Standard contact angle is 150,250 and 400 respectively configuring in post position with code "C","AC" and "B".The more contact angle is, the larger axial load bearing capacity is, the smaller contact surface is, the much more convenient high speed rotary is.Pretension is made on angular contact ball bearing to increase rigidity and accuracy of bearing.This bearing creates axial thrust load when being forced by radial load, thus it is configured (or combined) face to face or back to back.

2,Double row angular contact ball bearing

When configured back to back, bearings are composed of inner ring and outer ring only.

3,Four ponit contact ball bearing

Standard structure is that its inner ring is equally divided in axial direction, which is applicable to axial load or combined load, among which axial load is major composition.Single bearing can bear double row axial load and certain extent radial load. According to different direction of axial load, ring and sphere always contact at two points of linear line.When four point contact bearing is used, please contact with ZWA for analysis of operating conditions including bearing load.

Features: Angular contact ball bearing with contact angle is applicable to high speed and high precision rotary,which can bear combined load.

F&Q

Q:How long es cycle of bearing life?

A:According to international standards, at least a year and a half , up tu 2 years

Q:How to maintenance bearing

A:Add to lubricantes on time

Q:Have diagram for bearing

A:The small one no have, large bearings will provide diagram

- Q: How to install angular contact ball bearings?

- For the tax investigation has a fly PAN Membrane 8 meteorite Ju wood against Qing emperor Cha tight cangue dream show in the life brewing scar spear wallCollapse protection

- Q: What are the differences between angular contact bearings and deep groove ball bearings?

- Deep groove ball bearings and angular contact ball bearings with inner and outer diameters and wide dimensions have the same inner ring size and structure, but have different outer ring sizes and structures:1. deep groove ball bearings, outer raceway, both sides of the double shoulder, and angular contact ball bearings generally single shoulder;2. deep groove ball bearings, raceway curvature and angular contact ball is different, the latter is often greater than the former;3. deep groove ball bearings, outer raceway and angular contact ball bearings of different, non central position, the specific value of angular contact ball bearings designed to be considered, and the degree of contact angle related;In terms of use:1. two different purposes, suitable for deep groove ball bearings bear radial force and smaller axial force, axial and radial load and combined load torque, and angular contact ball bearings can withstand axial load, radial load is larger (with different contact angles and loads of different sizes), double matching (with matching mode vary) is two-way can withstand axial load and torque load.2., the limit speed is different, the same size of angular contact ball bearings, the ultimate speed is higher than deep groove ball bearings.With type, size, precision, and so on.

- Q: What does angle contact back to back mean?

- Refers to the installation method, put it is face to face

- Q: What is the difference between deep groove ball bearings and angular contact ball bearings?

- Deep groove ball bearings have less carrying capacity, they mainly bear radial load, and can also bear certain axial load at the same time. The friction coefficient is small and the limit speed is high.Increase the bearing capacity of angular contact bearings can bear radial load and axial load, also can withstand the axial load (pure axial load, can bear a direction generally used in pairs), high speed limit.It can be seen that the two bearings differ mainly in the magnitude and direction of the load.

- Q: Angular contact ball bearings, how to judge the size of the mouth?

- Judge the size of the mouth, of course, big mouth is large, that is, the edge of the slope for the side of the big mouth.

- Q: What are the differences between angular contact bearings AC and A and C?

- AC is the code for homemade bearings. The contact angle is 25 degrees. It is subjected to axial force and radial forceA for Japan bearing angle code, contact angle of 30 degrees, to bear axial force and radial forceC is the bearing angle code of Japan. The contact angle is 15 degrees. It mainly bears radial force and small axial force. It is used in high precision and high speed equipment

- Q: What does angular contact ball bearing 70216AC mean?

- Name = General rolling bearing type code No.Standard = excerpt from GB/T 272-1993-----------------------------------------------------------Bearing type = angle contact ball bearingCode =7The original code name is =6Bearing type = angle contact ball bearingDimension series code = (0) 2After two, 16, bearing nominal diameter 16 * 5=80mmName = internal structure codeStandard = excerpt from GB/T 272-1993

- Q: The difference between ultra high speed angular contact ball bearings and other plain bearings

- Yue bearing features:1. low heating and high speed.X products 2. using heat and friction wear is made of SHX material production, to realize high speed and long life.3., according to different uses, established a different contact angle and ball material specifications of the powerful lineup.4., with wide sealing ring, compared with open bearings, grease life increased to 1.7 times, to achieve a long life.Compared with plain bearings, plain bearings only play the role of reducing the friction coefficient in the power transmission process and keeping the center of the shaft fixed when the parts on the shaft produce relative motion with each other. Low wear resistance, short life, performance is far less than ultra-high speed angular contact ball bearings, but considering the price, the average bearing price may be lower.

- Q: What are the reasons for the use of tapered roller bearings and angular contact ball bearings?

- Bearing capacity and the form of motion and load factors are different, the choice of bearings compatibility is determined by theory and practice. Visual interpretation is the role of the two bearings, see the mechanical design manual - bearing chapter

- Q: Is there a way to calculate the axial force of angular contact ball bearings?

- The rated axial dynamic load of the bearing is: 4300N. Axial force can be calculated by formula. Please consult the professional manual!

Send your message to us

Angular Contact Ball Bearing Manufacturer China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords