Bearings single row tapered roller, model 32028 top selling

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

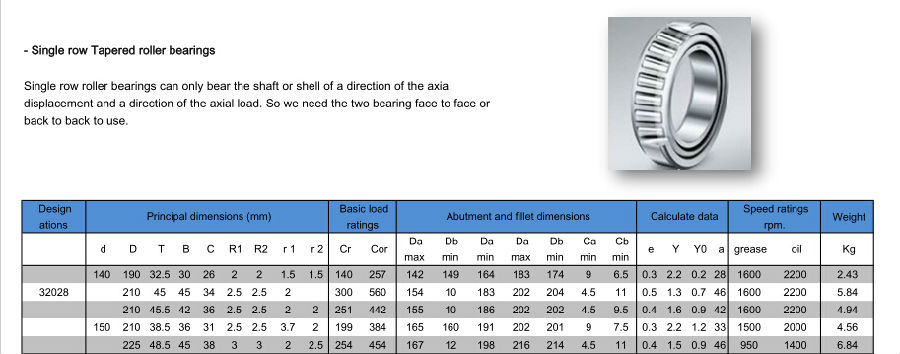

- Single row Tapered roller bearings

Single row roller bearings can only bear the shaft or shell of a direction of the axial

displacement and a direction of the axial load. So we need the two bearing face to face or

back to back to use.

★Product features

The inner and outer ring raceways are segments of cones and the rollers are also made with a taper so that the conical surfaces of the

raceways and the roller axes if projected, would all meet at a common point on the main axis of the bearing. The rollers are guided by a

flange on the inner ring. This stops the rollers from sliding out at high speed due to their momentum. The larger the half angles of these

cones the larger the axial force that the bearing can sustain.

★Product application

In many applications tapered roller bearings are used in back-to-back pairs so that axial

forces can be supported equally in either direction.

Pairs of tapered roller bearings are used in:

- car and vehicle wheel

- mining equipment

- moderate speed

- engine motors

- axle systems

- construction

- agriculture

- reducers

- gear box

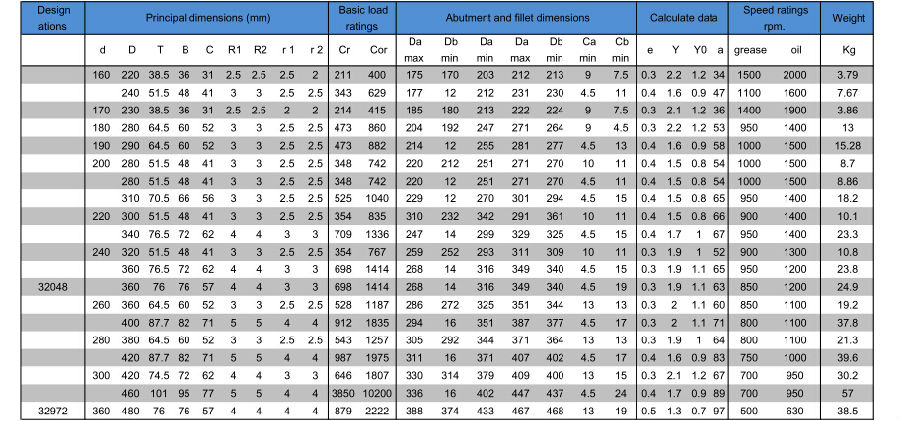

★Horton tapered roller bearings Basic size

- Single row tapered roller bearings:

Inner ring size: 20mm ~ 1270mm Outer ring size: 40mm ~ 1460mm Width size: 15mm ~ 240mm

- Double row tapered roller bearings:

Inner ring size: 38mm ~ 1560mm Outer ring size: 70mm ~ 1800mm Width size: 50mm ~ 460mm

- Four row tapered roller bearings:

Inner ring size: 130mm ~ 1600mm Outer ring size: 200mm ~ 2000mm Width size: 510mm ~ 1150mm

★Tolerance:

Horton tapered roller bearing with common

tolerance, and also provides P6X, P6, P5, P4,

★Radial clearance

Horton single row tapered roller bearings only

in after installation have clearance, and in

★Cage

Tapered roller bearing general ues the steel plate stamping, basket shape cage, but when the size is bigger, we

also adopts entity cage.

1. Outside diameter D ≤ 650mm, use the steel plate stamping cage, cage postposition without code mark.

2. Outside diameter D > 650 mm, use the steel entity prop cage, cage postposition without code mark.

★Dynamic equivalent load

P = Fr [KN], Fa / Fr ≤ e;

P = 0.4Fr + YFa [KN], Fa / Fr > e.

The single row tapered roller bearings used in pairs (basic physical size can be different), when calculation the

equivalent dynamic load of the bearing, must be included in the radial load cause additional axial force. The single

row tapered roller bearing additional axial force S, can approximate formula: S = Fr / 2y

★Static equivalent load

Single row tapered roller bearings

P0 = 0.5Fr + Y0Fa [KN] P0 < Fr, then P0 = Fr

Double row tapered roller bearings

P = 0Fr + Y1Fa [KN],Fa/Fre ≤e P = 0.67Fr + Y2Fa [KN], Fa/Fre > e

- Q: What are the conditions for the normal and reverse loading of tapered roller bearings?

- 2. anti loaded (outer ring width relative end) horns contact ball bearing or tapered roller bearing pressure center distance is greater than two at the midpoint of the bearing span, known as anti loading, obviously, axial thermal expansion will increase the axial clearance of bearing. In addition, the structure of reverse loading is more complicated, and it is inconvenient to assemble, disassemble and adjust.Stiffness analysis of positive and negative when the transmission parts of cantilever installation, shaft reverse mounting stiffness ratio of forward shafting high, this is because the distance from the center of pressure bearing with large, maximum bending moment of the bearing force, deformation and axial deformation and are less formal.

- Q: Is the tapered roller bearing so correct?

- Tapered roller bearingTapered roller bearings are designed for the inner ring, outer ring raceway and roller cone vertex on the central axis of the bearing, radial load acting on the bearing, axial force is generated. Therefore, it is necessary to use the 2 bearings for use, or as double pairs of bearings, double row bearings. Combination and double row tapered roller bearings, when radial loads act on tapered roller bearings

- Q: What are the E and Y values of the 30209 bearings of tapered roller bearings?

- The shoulder of the positioning shaft is positioned; the transition shaft shoulder is provided for the disassembly of the parts on the shaft or the prevention of the stress concentration. But the axial shoulder will inevitably increase the diameter of the shaft, and the shoulder of the axle will change due to the stress concentration.

- Q: What items should be inspected for tapered bearings?

- 2, tapered roller bearings are not allowed to have an electric drill pattern, vibration patterns, yin and Yang face and polished traces, did not promise to emerge supporting construction and obvious measurement traces, did not agree to knock bumps and obvious color difference.3, the name of the whole machine did not promise to have oxide skin.

- Q: Tapered roller bearing: Bearing expert why burned or locked

- 2, the bearing seat hole size deviation is too small or the size of the shaft deviation is too large, extrusion bearing ring deformation, make the clearance smaller. To burn locking phenomenon.3, bearing outer diameter and bearing seat hole, or between the bearing bore and the surface of the shaft between the foreign body, such as iron filings, burr, sand, cotton and so on. Will also squeeze bearing deformation, so that smaller clearance. To burn locking phenomenon.Bearing burnt lock. The cause of the accident can be analyzed according to the burning degree of the inner shell, the outer shell and the roller1. The inner shell burns most severely, the roller slightly lighter, and the outer shell almost does not change. After excluding the reasons for the nonstandard size of the inner bearing housing, the following judgment can be made.

- Q: What is the 30207 judgment coefficient e of tapered roller bearings?

- Your adoption is the driving force of my progress~~O (a O, a _) remember praise and adoption, help each other.

- Q: that is to say, the taper head is the face and the back is the back

- The bearings do not have to distinguish between the front and back, and there is no positive and negative said, only in accordance with your actual use to identify the installation direction.

- Q: Tapered roller bearing suffix code YA2 stands for what does that mean?

- Mr. Liu five love reading, "gladly forget to eat" every knowing; ong drinking is not wine, but for mountains and rivers ". So Mr. Qian Zhongshu proposed" all happiness enjoy all belong to the spirit of "the world as truth, but think, feel spiritual satisfaction is also flawed, sometimes even the feeble.

- Q: What are the general uses of tapered roller bearings?

- Widely used in machinery and equipment, water conservancy and Hydropower Engineering, railway, automobile, steel, textile, packaging, medicine, metallurgy, mining, petroleum, electric power, papermaking, computer, motor, sports equipment, office equipment, instrumentation, auto motor, precision instruments and other fields

- Q: Turbine turbo rod reduction box, tapered roller bearing at both ends of wormGap measuring method, tapered roller bearingsThe gap is +-0.03, so how do I know the gap is in the range?.

- You can measure the oil gap with a drop bar, that is, a soft drop ruler, which can be purchased without measuring the instrument of the bearing

Send your message to us

Bearings single row tapered roller, model 32028 top selling

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords