32007 Tapered Roller Bearigs Single Row Bearing

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 500000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

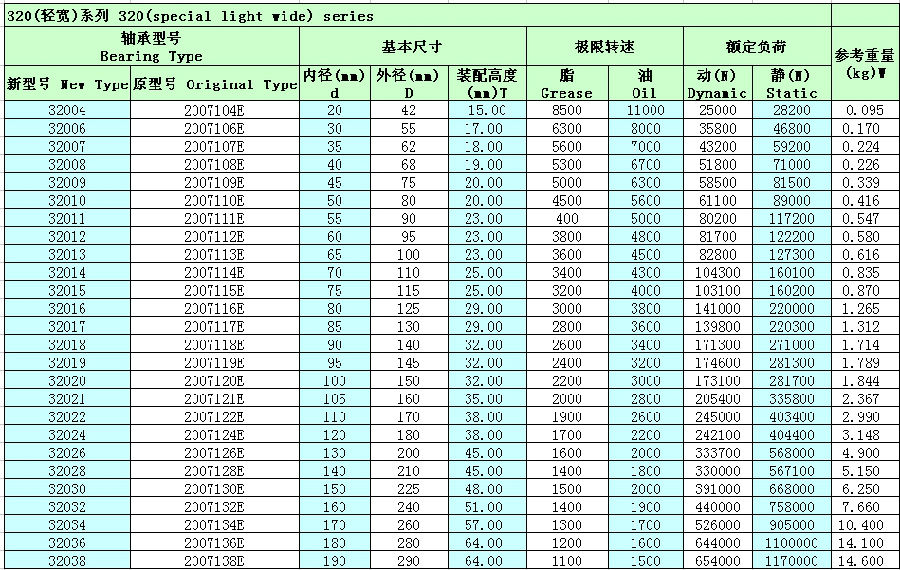

Specificatioin of Taperder Roller Bearings:

The tapered roller bearing is to bear the combination of radial and axial load but mainly afford radial load. The loading capibility is determined by the raceway angle of outer ring, the larger angle afford larger load. This kind of bearings can be seperated and it can be divided into single-row and double-row tapered roller bearings by the number of columns. The clearance for single-row tapered roller bearing should be adjusted by the customers when installation. For the double-row tapered roller bearings,the clearance has already set by the manufacture before ex-factory. Tapered roller bearing has taper shaped inner ring and outer ring raceway,and the roller elements arrange between them. All projection lines from the surface of rollers meet at the same point on bearing axis. This design makes tapered roller bearings particular suitable for combined (axial and radial) loads.The axial loading capacity is determined by the contacting angle α, the bigger angle for α, the larger axial loading capacity is. Tapered roller bearing is usually a seperated bearing, that is,the inner ring assembly including roller and cages, is seperated installed with the cup.

Taper roller bearings are mainly used for radial and axial joint load with radial load as main subject. Axial load capacity relies on raceway angle of outer ring: the bigger the angle is, the bigger the bearing capacity is. Outer ring can be separated and can be easily assembled. During installing and using process, axial clearance and radial clearance and radial clearance can be adjusted and pre-interference installation can be allowed.

Product application:

In many applications tapered roller bearings are used in back-to-back pairs so that axial forces can be supported equally in either direction.

- car and vehicle wheel

- mining equipment

- moderate speed

- engine motors

- axle systems

- construction

- agriculture

- reducers

- gear box

- Q:Online cylinder cones are GB/T4663, what do you mean?

- Which size do you want, eldest brother? How do I make so much?GB/T: recommended national standards; GB: mandatory national standards4663: taper roller national standard codeThere is a missing release year later!It should be: GB/T 4663-1994

- Q:that is to say, the taper head is the face and the back is the back

- The installation of tapered roller bearings is not only to pay attention to the direction of installation, there are many other places to pay attention to, is a very professional technical activities

- Q:What are the general uses of tapered roller bearings?

- At the time of greater radial load and axial load

- Q:What items should be inspected for tapered bearings?

- 4, tapered roller bearing ring after the whole machine after pickling, there should be no scald, the name of cooperation should not be a pickling visible traces of burns, and no response angle detection.Tapered roller bearing appearance should be smooth, lubrication, no plants, no scratches, no rust and no obviously difference, promised to pressure injury, damage, deformation and defects such as trachoma vipassana.

- Q:What are the conditions for the normal and reverse loading of tapered roller bearings?

- Hello, I'm Camry KMR bearingsTapered roller bearings are generally used in pairs, according to the adjustment, installation and use of different occasions, there are two following arrangement. The 1. suits (outer ring relatively narrow end) corner contact ball bearing or tapered roller bearing pressure center distance is less than two bearing mid span, called dress. The shafting of this method is simple in structure, easy to assemble, disassemble and adjust, but the heating elongation of the shaft will reduce the axial clearance of the bearing and even die.

- Q:What does "tapered roller bearing" suffix "A" mean?

- Tapered roller bearing suffix AA - angular contact ball bearings with a contact angle of 30 degreesA5 - angular contact ball bearings with a contact angle of 25 degrees

- Q:Taper roller bearings limit speed, according to what to calculate, there is no formula for what?

- First of all, different types of tapered roller bearings, the limit speed is different. Bearing on catalog.Second, the calculation of bearing limit speed is calculated by computer simulation of bearing manufacturer. It is very complicated. Mainly based on frictional heat generation and cage strength limit.

- Q:How does the roller of tapered roller bearings fit in?

- Tapered roller bearings in the production of equipment, it is the first roller and cage assembly, and then into the inner ring, composed of components. Tapered roller bearings as long as the assembly, even if completed the inner ring, because the outer ring is only one ring.I don't know if you'll understand.

- Q:The roller of tapered roller bearings is cylindrical or cylindrical body? Why roller drawing method of drawing section for the rectangular (here I want to add: I have seen the N version, some of the paintings is rectangular, trapezoidal and some paintings, 2 versions, a few of my book is that the proportion is A/2 the roller projection) it indicates that the real roller should be a cylinder or a cylindrical body roller is... What master?

- Cylindrical rollers are used only when the raceway is a cylinder.Mechanical drawing clearly stipulates the simplified drawing method of tapered roller bearings. Rollers are drawn into cylinders.

- Q:Tapered roller bearing: Bearing expert why burned or locked

- 2, the bearing seat hole size deviation is too small or the size of the shaft deviation is too large, extrusion bearing ring deformation, make the clearance smaller. To burn locking phenomenon.3, bearing outer diameter and bearing seat hole, or between the bearing bore and the surface of the shaft between the foreign body, such as iron filings, burr, sand, cotton and so on. Will also squeeze bearing deformation, so that smaller clearance. To burn locking phenomenon.Bearing burnt lock. The cause of the accident can be analyzed according to the burning degree of the inner shell, the outer shell and the roller1. The inner shell burns most severely, the roller slightly lighter, and the outer shell almost does not change. After excluding the reasons for the nonstandard size of the inner bearing housing, the following judgment can be made.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

32007 Tapered Roller Bearigs Single Row Bearing

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 500000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords