Tapered Roller Bearigs Singal Row Tapered Roller Bearing low noise high precision

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 500000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

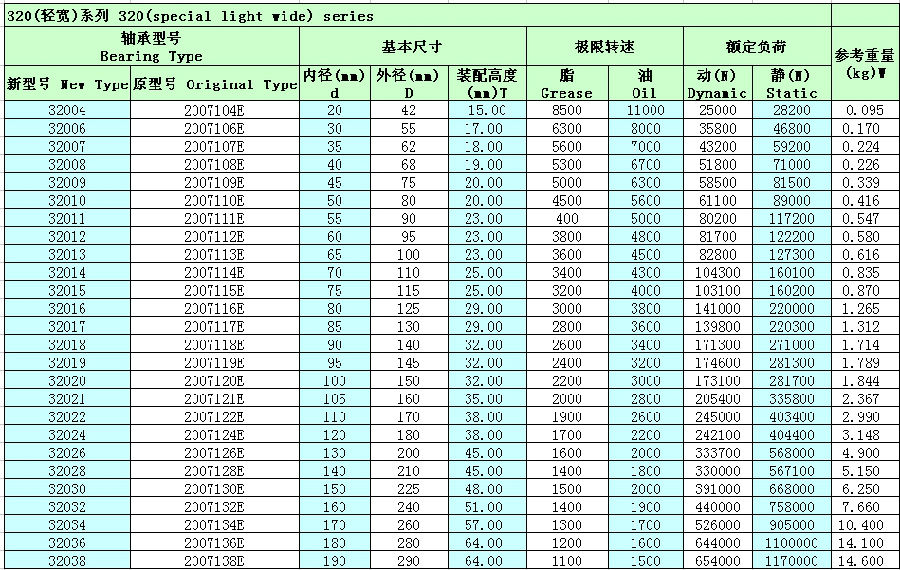

Specificatioin of Taperder Roller Bearings:

The tapered roller bearing is to bear the combination of radial and axial load but mainly afford radial load. The loading capibility is determined by the raceway angle of outer ring, the larger angle afford larger load. This kind of bearings can be seperated and it can be divided into single-row and double-row tapered roller bearings by the number of columns. The clearance for single-row tapered roller bearing should be adjusted by the customers when installation. For the double-row tapered roller bearings,the clearance has already set by the manufacture before ex-factory. Tapered roller bearing has taper shaped inner ring and outer ring raceway,and the roller elements arrange between them. All projection lines from the surface of rollers meet at the same point on bearing axis. This design makes tapered roller bearings particular suitable for combined (axial and radial) loads.The axial loading capacity is determined by the contacting angle α, the bigger angle for α, the larger axial loading capacity is. Tapered roller bearing is usually a seperated bearing, that is,the inner ring assembly including roller and cages, is seperated installed with the cup.

Taper roller bearings are mainly used for radial and axial joint load with radial load as main subject. Axial load capacity relies on raceway angle of outer ring: the bigger the angle is, the bigger the bearing capacity is. Outer ring can be separated and can be easily assembled. During installing and using process, axial clearance and radial clearance and radial clearance can be adjusted and pre-interference installation can be allowed.

Product application:

In many applications tapered roller bearings are used in back-to-back pairs so that axial forces can be supported equally in either direction.

- car and vehicle wheel

- mining equipment

- moderate speed

- engine motors

- axle systems

- construction

- agriculture

- reducers

- gear box

- Q: Taper roller bearings are used on my motor. Serious damage occurred during use. Please help me analyze the possible causes of damage! Thank you

- To LZ: 1 it is recommended that the radial force and the rated load of the bearing be compared to determine whether the radial force is too large (if there is axial force, it needs to be synthesized as equivalent load, and then compare.) In 2 section, you basically is the middle of the two row tapered bearing ring and then as a double row tapered to use (not in general, so natural clearance installed back to back) without gasket or nut to adjust, this is a very good idea.

- Q: you master good! Ask a question about the use of tapered roller bearings: a mechanism using a double row tapered roller bearings, but did not buy this model, can use two single row tapered roller bearing together instead of double row?

- 2, the clamping way is: double row bearing inner ring is double row, or outer ring double, determines when you install the inner ring or outer ring is clamped, clamped, if you want to replace with the two row, when combined with the clearance you need to consider the ring, you should adjust the clearance and is placed on the inner ring, or on the outside, too that depends on your way of clamping;

- Q: The installation of tapered roller bearings

- 1, for example, a shaft needs to be fitted with two such bearings at both ends. Can it be installed in the same direction?The force of the shaft is concerned. If the shaft is indeed subjected to one-way axial force, of course, it can be installed in the same direction. If it is subjected to biaxial axial force, it will not work

- Q: Tapered roller bearings. Are the rollers tapered?

- The frustum of the cone can be seen as a right angled trapezoid revolving around the right angle, and the top is a circle. Can also be seen on top of the tip is tapered off, the tapered roller head is not a round face

- Q: What does "tapered roller bearing" suffix "A" mean?

- Tapered roller bearing suffix AA - angular contact ball bearings with a contact angle of 30 degreesA5 - angular contact ball bearings with a contact angle of 25 degrees

- Q: The device is a vertical axis vertically arranged in the bearing chamber, the upper shaft without suspension, supported by bearings, shaft bearings are installed at the bottom of the outdoor rotating parts weighing 50 kg, the two ends of the shaft are used in single row tapered roller bearings, the bearings between the length of 30 meters. The rotation speed of the shaft is 480r/min. The device is suspended on a rotating turntable and is subjected to centrifugal force during operation...

- Why not such a large selection of axial thrust bearing, if the radial force selected contact angle greater than 45 degrees (thrust) tapered roller bearings or spherical roller bearings are good, ordinary radial cone bearing axial force mainly depends on the inner ring rib, movement and rib roller end surface contact of gyro rotation, life too effect of axial force, and excessive axial force will make rib fracture.

- Q: What is the 30207 judgment coefficient e of tapered roller bearings?

- What do you need to see for yourself?:Tapered roller bearings: 30207Internal diameter d:35mmOutside diameter D:72mmInner ring height B:17mmOuter ring height C:15mmTotal height (assembly height) T: 18.25mm

- Q: Tapered roller bearing suffix code YA2 stands for what does that mean?

- Mr. Liu five love reading, "gladly forget to eat" every knowing; ong drinking is not wine, but for mountains and rivers ". So Mr. Qian Zhongshu proposed" all happiness enjoy all belong to the spirit of "the world as truth, but think, feel spiritual satisfaction is also flawed, sometimes even the feeble.

- Q: What are the general uses of tapered roller bearings?

- Widely used in machinery and equipment, water conservancy and Hydropower Engineering, railway, automobile, steel, textile, packaging, medicine, metallurgy, mining, petroleum, electric power, papermaking, computer, motor, sports equipment, office equipment, instrumentation, auto motor, precision instruments and other fields

- Q: Turbine turbo rod reduction box, tapered roller bearing at both ends of wormGap measuring method, tapered roller bearingsThe gap is +-0.03, so how do I know the gap is in the range?.

- You can measure the oil gap with a drop bar, that is, a soft drop ruler, which can be purchased without measuring the instrument of the bearing

Send your message to us

Tapered Roller Bearigs Singal Row Tapered Roller Bearing low noise high precision

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 500000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords