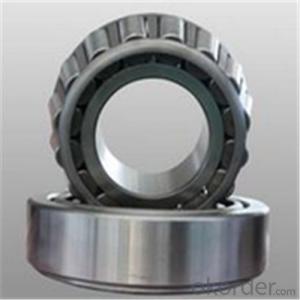

Cylindrical Roller Bearing Manufacturer China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Cylindrical Roller Bearing

Description

Cylindrical roller bearings have no ribs on either the inner or outer ring, so therings can move axially relative to each other. These can be used as free-end bearings. Cylindrical roller bearings, in which either the inner or outer rings has two ribs and the other ring has one, are capable of taking some axial load in one direction Double-row cylindrical roller bearings have high radial rigidity and are used primarily for precision machine tools.Cylindrical roller bearings are available in many designs, series and sizes. The majority are single row bearings with a cage. High-capacity bearings, single and double row full complement bearings (without a cage) complete the international standard assortment listed.

Features

1.) Offers a complete range, both metric and inch sizes available in metric and

imperial bore sizes ranging from 12 to 1320 mm.

2.)High radial load capacity - making cylindrical roller bearings suitable for high

speed applications.

3.)Designs - designated NU, NJ, NUP, N or NF for single row bearings and NNU or

NN for double row types, defines the bearing ring rib configuration.

4.) Cages - Available with pressed steel, machined brass and polyamide cages

throughout the range.

5.) Special designs - manufactures a range of four-row cylindrical roller bearings,

primarily designed for use as steel mill roll-neck bearings.

6.)Bearings are also available with both lubrication holes and a machined

lubrication groove on the outside surface of the outer ring.

Application of cylindrical roller bearings:

Cylindrical roller bearings are used in a variety of applications. Examples include mining, petroleum production, power generation, power transmission, cement processing, aggregate crushing, and metal recycling. Some cylindrical roller bearings are used in briquetting machines, rubber mixing equipment, rolling mills, rotary dryers, or pulp and paper machinery. Others are used in construction equipment, crushers, electric motors, blowers and fans, gears and drives, plastics machinery, machine tools and traction motors and pumps.

F&Q

Q:How long es cycle of bearing life?

A:According to international standards, at least a year and a half , up tu 2 years

Q:How to maintenance bearing

A:Add to lubricantes on time

Q:Have diagram for bearing

- Q: How much is the shaft shoulder height of the 81105 cylindrical roller bearings with inner diameter 25mm?

- The shoulder height (diameter) shall be smaller than the big diameter of the bearing (less than 42), mainly for easy unloading.

- Q: Double row full cylindrical roller bearings, NNCF5008 installation, we need to pay attention to the direction of it?

- Double row cylindrical roller bearings have no directionality, so they do not need to pay attention to the direction! However, it should be noted that the inner ring and outer ring should be positioned separately to prevent axial movement!

- Q: How to check the thrust cylindrical roller bearings?

- This data is the minimum axial load, not the maximum axial load.

- Q: Can the Nu and N type NJ NUP cylindrical roller bearings bear axial force?

- The answer upstairs is clear. Such bearings can not be designed with axial force. In use, the inner and outer rings of the bearing can have larger axial displacement, and the aim is to compensate the length change caused by the rotating part of the two bearing due to the temperature rise.

- Q: cylindrical roller bearings N210 20Deep groove ball bearings 6120, self-aligning ball bearings 1210, cylindrical roller bearings N210 in the same radial force conditions, the life expectancy of the three levels and how to compare? What is the cause of the high and low?

- The cylindrical roller bearings are in line contact with the outer ring of the bearing, and have the largest contact surface with the outer ring of the bearing. And the large contact surface means that in the same radial force, the same speed, friction, and thus generate more heat, and thus affect the life.

- Q: Why cylindrical roller bearings can not bear axial load?.

- Bearing bearing axial force or radial force is determined by the structure of the bearing, thrust ball bearings are also called plane bearings, which are mainly used to bear axial force; cylindrical roller bearings can bear radial forces and are not suitable to bear axial force.

- Q: How should I find the concentricity of cylindrical roller bearings after installation?

- Any form of assembly, adjustment center is a very troublesome thing, but also in the measuring installation is not very complete, the usual method is to in the base below (or below) thin copper with different thickness, until you feel better, but each installation to re adjust. So, in the machining process, try to use special fixtures and parts drawing in tol and other measures to avoid such a remedy".

- Q: What does "cylindrical roller bearing" ENV mean?

- Cylindrical roller bearings, the basic model suffix ENV meaning:E: enhanced design with improved bearing load capacityN: the outer ring of the bearing is provided with a stopping grooveV: full installed roller (no cage)

- Q: Why are there no double row cylindrical roller bearings in the mechanical design manual?

- Normally, the inner diameter of the bearing should be in interference fit with the shaft (for some light loads, too, with a transition fit).

- Q: Thrust cylindrical roller bearings, the main use?

- Thrust cylindrical roller bearings, the main use? Thrust cylindrical roller bearings are mainly used in oil rigs, iron, steel, machinery and so on. Our factory uses the bearings of Changzhou Enke Bearing Co., Ltd., they have many kinds of bearings and meet various demands.

Send your message to us

Cylindrical Roller Bearing Manufacturer China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords