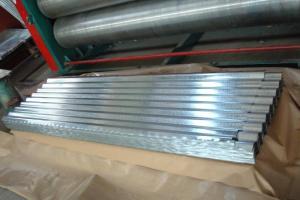

Steel Specification:

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Technical

Specification Clear step on gray scale 3rd step, clear

Dot reproduction(%) 2-98%

Micro-line(impression) 6-12

Pressrun(impression) ≥50,000

Storage condition Temp:10-30℃, RH:Rh≤65%,

2years

Recommended

Processing

Conditions Dilution ratio GD-II : water=1:4(machine)

1:6(hand)

EXPLOSURE(UNIT) 35-50

Developing Temp(℃) 21-25

LIGHT SOURCE 3000W (LODINE GALLIUM LIGHT:100-120 SECONDS)

1METER(FOR DISTANCE)

Developing Time(S) 30-45

Contamination removal Retouching paste: 40s

Retouching solution: 10s

Gumming A even, thin coating, 20ml/㎡

Baking Normally unnecessary, if need

Oven-type: 240℃,4-5mins

Moving-type: 260℃,3-4mins

- Q: How are steel coils used in the production of agricultural systems?

- Due to their durability and strength, steel coils are frequently employed in the production of agricultural systems. Specifically, these coils are commonly utilized in the creation of machinery and equipment essential for agricultural operations. One prevalent use of steel coils lies in the manufacture of farming machinery such as tractors, plows, and cultivators. These machines necessitate robust components capable of enduring the challenging conditions present in the agricultural environment. Steel coils are employed to fabricate the frames, chassis, and other structural parts of these machines, providing the necessary strength and support. Additionally, steel coils are employed in the creation of irrigation systems, which play a crucial role in efficient water management within agriculture. These coils are employed in the construction of pipes, valves, and fittings, ensuring the durability and long-lasting nature of the irrigation system. Furthermore, steel coils are employed to fabricate storage tanks and silos, which serve as vital tools for storing and preserving agricultural products like grains, seeds, and fertilizers. Moreover, steel coils find application in the construction of greenhouses and agricultural buildings. These coils are used to fabricate the structural framework, providing stability and resistance against environmental factors. Steel coils are also employed in the production of fencing and enclosures to safeguard crops and livestock from external threats. In conclusion, steel coils play a significant role in the production of agricultural systems by delivering the necessary strength, durability, and stability required for farming machinery, irrigation systems, storage facilities, and agricultural structures. Their utilization ensures that these systems can withstand the demanding conditions of the agricultural industry and contribute to efficient and sustainable farming practices.

- Q: How are steel coils used in the manufacturing of electrical transformers?

- Steel coils are used in the manufacturing of electrical transformers as they provide structural support and act as a core for the transformer. The steel coils are wound with copper wire to create the primary and secondary windings, which help in transferring electrical energy efficiently.

- Q: What are the different types of surface defects in steel coils?

- Some common types of surface defects in steel coils include scratches, pits, rust, scaling, laminations, and waviness.

- Q: What are the safety precautions when working with steel coils?

- Some safety precautions when working with steel coils include wearing appropriate personal protective equipment (PPE) such as gloves, safety glasses, and steel-toed boots, ensuring proper lifting techniques to prevent musculoskeletal injuries, maintaining a clear and organized work area to avoid tripping hazards, using proper machinery and equipment to handle and transport the coils safely, and following established safety protocols and procedures. It is also important to receive proper training and supervision to handle steel coils effectively and minimize potential risks.

- Q: What is the purpose of steel coils?

- The purpose of steel coils is to efficiently store and transport large quantities of steel in a compact and organized manner.

- Q: Can steel coils be used in the manufacturing of machinery and equipment?

- Yes, steel coils can be used in the manufacturing of machinery and equipment. Steel coils are versatile components that provide strength, durability, and stability to various industrial applications. They can be shaped, cut, and formed into different parts and components necessary for the machinery and equipment manufacturing process. Steel coils are commonly used in the production of gears, shafts, frames, brackets, and other structural elements. Additionally, they can be processed further to create specialized components such as springs or fasteners. The use of steel coils in machinery and equipment manufacturing ensures that the end products are of high quality, capable of withstanding heavy loads, and have a long lifespan.

- Q: How are steel coils used in the manufacturing of agricultural trailers?

- Steel coils are used in the manufacturing of agricultural trailers to provide strength, durability, and stability to the trailer's frame, ensuring it can withstand heavy loads and harsh working conditions. These coils are typically shaped and welded to create the trailer's structural components, such as the chassis, sidewalls, and flooring. Additionally, steel coils can be cut and formed into various parts, including axles, suspension systems, and hitch assemblies, to further enhance the trailer's performance and functionality in agricultural operations.

- Q: What are the main factors that affect the flatness of steel coils?

- The main factors that affect the flatness of steel coils are the quality and thickness of the steel material, the tension and speed of the rolling process, the temperature and cooling rate during the cooling process, and any potential defects or imperfections in the machinery used for rolling and cooling the steel coils.

- Q: How do steel coils compare to aluminum coils?

- Steel coils are generally stronger and more durable than aluminum coils. They have a higher tensile strength and better resistance to impact and abrasion. However, aluminum coils are lighter, more corrosion-resistant, and have better thermal conductivity. The choice between steel and aluminum coils depends on the specific application and the desired characteristics such as strength, weight, and corrosion resistance.

- Q: What are the pros and cons of non-stick and stainless steel pots and pans ?Thanks

- NEVER cook eggs in anything other than a nonstick pan. They stick real good! Though nonstick surface does wear off eventually and you have to get new ones..

Send your message to us

Steel Specification:

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords