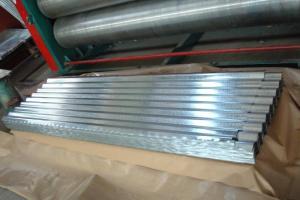

GALVANIZED CORRUGATED STEEL

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

product information:

1)Operate Standard: ASTM A653M-04/JIS G3302/DIN EN10143/GBT 2518-2008

2)Grade : SGCD,SGCH, Q195,DX51D

3)Galvanized steel sheet /coil features:

4)Zinc coating :40-180g( as required)

5)width:914-1250mm(914mm, 1215mm,1250mm,1000mm the most common)

6)coil id:508mm/610mm

7)coil weight: 4-10 MT(as required)

8)surface: regular/mini/zero spangle, chromated, skin pass, dry etc.

9)application: Structural use ,roofing, commercial use, household appliance, industry, family;

special application: Wear resistant steel, high- strength - steel plate

Technical data :

Chemical Composition | ||||||

GRADE | C | Si | Mn | P | S | Ti |

SGCC/DX51D+Z | ≤0.10 | ≤0.50 | ≤0.60 | ≤0.10 | ≤0.030 | ≤0.020 |

DX52D+Z | ≤0.10 | ≤0.50 | ≤0.60 | ≤0.10 | ≤0.030 | ≤0.020 |

SGCD/DX53D+Z | ≤0.10 | ≤0.30 | ≤0.50 | ≤0.05 | ≤0.030 | ≤0.020 |

SGCE/DX54D+Z | ≤0.10 | ≤0.30 | ≤0.30 | ≤0.03 | ≤0.020 | ≤0.020 |

DX56D+Z | ≤0.10 | ≤0.30 | ≤0.30 | ≤0.03 | ≤0.020 | ≤0.020 |

Structural | ≤0.20 | ≤0.60 | ≤1.70 | ≤0.10 | ≤0.045 | |

hot dipped galvanized steel coil Mechanical Properties | |||

GRADE | Yield Strength MPa | Tensile Strength MPa | Elongation % |

SGCC(DX51D+Z) | ≥205 | ≥270 | - |

SGCD(DX53D+Z) | - | ≥270 | 38 |

SGCE(DX54D+Z) | - | ≥270 | 40 |

DX56D+Z | - | ≥270 | 42 |

- Q: I bought this Brinks pad lock and it says boron steel on the lock. I was just wondering what exactly is boron steel and how hard/tough is it?

- Boron steel is rather hard, it is by no means titanium, but certainly better than mild steel. However, as with all metals, hardness is inversely proportional to flexibility, meaning that a good solid whack with a sledge hammer could crack your lock.

- Q: How are steel coils used in the production of oil and gas equipment?

- Steel coils are used in the production of oil and gas equipment as they are shaped and formed into various components such as pipes, tubes, and fittings. These coils provide the necessary strength, durability, and corrosion resistance required for the harsh operating conditions in the oil and gas industry. Additionally, steel coils are often used in the fabrication of storage tanks, pressure vessels, and offshore platforms, ensuring the safe and efficient extraction, processing, and transportation of oil and gas resources.

- Q: What are the different methods of tension leveling for steel coils?

- There are several methods of tension leveling for steel coils, including roller leveling, stretcher leveling, and temper leveling. In roller leveling, the coil passes through a series of rollers that apply pressure to remove the internal stresses and flatten the material. Stretcher leveling involves stretching the coil beyond its yield point to remove the unevenness and then allowing it to spring back to a flat state. Temper leveling uses heat treatment to relieve the internal stresses and bring the coil to a flat condition. These methods provide different ways to achieve a level and flat surface for steel coils.

- Q: What are the common defects found in steel coils?

- Some common defects found in steel coils include surface defects like scratches, indentations, and pits, as well as internal defects such as cracks, lamination, and segregation. Other defects can include edge wave, coil breaks, and coil set.

- Q: How are steel coils used in the manufacturing of industrial machinery?

- Steel coils are used in the manufacturing of industrial machinery as raw material for various components, such as frames, brackets, and supports. The coils are processed by cutting, bending, and shaping to create specific parts that provide stability, strength, and structure to the machinery. Additionally, steel coils are often used for creating gears, shafts, and other moving parts that require high durability and resistance to wear and tear.

- Q: I also heard Stainless holds up better againts rust, blue steel needs more care.

- Stainless steel requires less maintenance, but I've got a K-38 Combat Masterpiece from 1974. Back then SW used the real blueing process, and the blue steel looks like its a foot deep. Probably the best looking gun in the accumulation. Still new in the box, never fired. Its my Vietnam tribute gun, same one I carried as a Security Policeman in the Air Force from 1969-1971.

- Q: what do they use to make stainless steel?and can stainless steel be melted again and again without losing it's Specifications

- Components Of Stainless Steel

- Q: How are steel coils used in the manufacturing of marine equipment?

- Steel coils are commonly used in the manufacturing of marine equipment as they provide a strong and durable material for various applications. These coils are often shaped, cut, and formed into different components such as hulls, propeller shafts, and structural supports. The high tensile strength of steel coils ensures the equipment's ability to withstand the harsh conditions of marine environments, including corrosion and pressure from waves and currents. Additionally, steel coils can be easily welded, making them suitable for constructing larger structures like ship decks and bulkheads.

- Q: Can steel coils be used in marine environments?

- Although steel coils can be utilized in marine environments, it is crucial to take necessary precautions to avoid corrosion. Given that steel is susceptible to corrosion when exposed to moisture and saltwater, which are commonly found in marine environments, it is imperative to employ protective measures on the steel coils. One such method is treating them with protective coatings like galvanization or painting to establish a shield between the steel and the corrosive elements. Moreover, regular maintenance and inspections should be conducted to detect any signs of corrosion and promptly address them to prevent further harm. By implementing these measures, steel coils can be effectively employed in marine environments while minimizing the risk of corrosion and ensuring their durability and performance.

- Q: How are steel coils used in the production of metal bridges?

- Steel coils are used in the production of metal bridges as they are rolled into the desired shape and size to form the structural components of the bridge, such as beams, girders, and support structures. These coils provide the necessary strength and durability to withstand the weight and stress of the bridge, ensuring its long-term stability and safety.

Send your message to us

GALVANIZED CORRUGATED STEEL

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords