All Categories

- - Steel Wire Rod

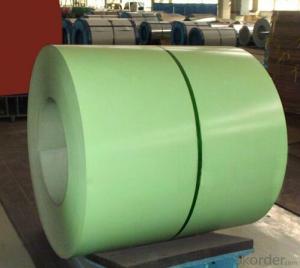

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

How are steel coils prepared for precision cutting in the metalworking industry?

Steel coils are prepared for precision cutting in the metalworking industry through a series of steps. First, the coils are inspected for any defects or imperfections. Then, they are straightened and flattened to ensure uniformity and consistency. Next, the coils are sheared to the desired width and length, followed by cleaning and deburring to remove any impurities or sharp edges. Finally, the coils are properly stacked and securely packaged for storage or transportation, ready for precision cutting processes.

How are steel coils tested for their resistance to abrasion and wear in heavy equipment?

Steel coils can be tested for their resistance to abrasion and wear in heavy equipment through various methods, such as conducting simulated wear tests using abrasive materials, subjecting the coils to continuous or cyclic loading to mimic real-life conditions, and evaluating the resulting wear and damage. Additionally, non-destructive testing techniques like ultrasonic testing can be employed to detect any internal defects that might affect the coil's durability. Overall, these testing procedures help determine the coil's performance and suitability for heavy equipment applications.

What is the significance of coil rolling direction?

The coil rolling direction is significant because it determines the mechanical properties and performance of the metal. It affects the grain structure, strength, ductility, and formability of the material, which in turn impacts its suitability for different applications. Additionally, the rolling direction can also influence the surface finish and appearance of the coil. Therefore, understanding and controlling the coil rolling direction is crucial in achieving desired material properties and ensuring quality in various industries such as automotive, construction, and manufacturing.

Wholesale Steel Coils from supplier in Japan

Our team is highly knowledgeable and experienced in the steel industry, ensuring that we can meet your specific requirements and provide the highest quality products. Whether you need hot-rolled steel coils, cold-rolled steel coils, or any other type of steel coil, we can source and deliver them to you promptly.

In addition to our sales and procurement services, we also offer comprehensive technical support. Our experts can provide guidance on the best steel coil products for your applications, as well as offer assistance with any technical issues or concerns you may have.

We understand the importance of efficiency and convenience in the procurement process. That's why we take pride in our reliable and timely delivery services. With our strong network and logistics capabilities, we can ensure that your steel coils are delivered to you in a timely manner, allowing you to stay on schedule and meet your project deadlines.

Partnering with us means not only receiving top-quality steel coils, but also benefiting from our extensive experience in the Japanese market. We have a proven track record of delivering successful projects in Japan, and we can leverage our expertise to provide valuable insights and recommendations for your projects.

Choose us as your trusted supplier of steel coils in Japan, and experience the efficiency, convenience, and expertise that we bring to every project. Contact us today to discuss your requirements and let us help you achieve success in your steel coil procurement endeavors.

In addition to our sales and procurement services, we also offer comprehensive technical support. Our experts can provide guidance on the best steel coil products for your applications, as well as offer assistance with any technical issues or concerns you may have.

We understand the importance of efficiency and convenience in the procurement process. That's why we take pride in our reliable and timely delivery services. With our strong network and logistics capabilities, we can ensure that your steel coils are delivered to you in a timely manner, allowing you to stay on schedule and meet your project deadlines.

Partnering with us means not only receiving top-quality steel coils, but also benefiting from our extensive experience in the Japanese market. We have a proven track record of delivering successful projects in Japan, and we can leverage our expertise to provide valuable insights and recommendations for your projects.

Choose us as your trusted supplier of steel coils in Japan, and experience the efficiency, convenience, and expertise that we bring to every project. Contact us today to discuss your requirements and let us help you achieve success in your steel coil procurement endeavors.