Stainless Steel Coil /Sheet in Wuxi, China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 6 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

stainless steel coil

1. Standard: ASTM A240, JIS G4304, G4305, GB/T 4237, GB/T 8165, BS 1449, DIN17460, DIN 17441

2. Grade: 200series&300series&400series

3. Thickness: 0.23mm-0.8mm

4. Diameter: 115-560mm

5. Length: according buyer require

6. Surface finish: 2B, BA, 8K, 6K, Mirror Finished, No1, No2, No4, Hair Line with PVC

7. Manufacture technology: cold drawn/cold rolled/hot rolled

1) Product feature:

| 1. Commordity: | stainless steel coil, stainless steel sheet |

| 2. Thickness: | 0.3mm~5.0mm |

| 3. Width: | 6mm~500mm, 1219mm, 1500mm |

| 4. Surface: | Shiny surface, 2B, 2R, BA |

| 5. Standard: | ASTM A240 |

| 6 Finishing: | Cold rolled + annealed |

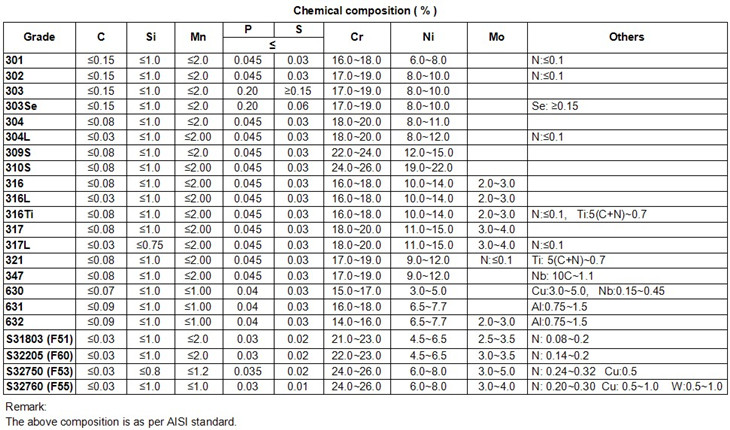

| 7. Materials: | 301, 304, 304L, 316, 316L, 316Ti, 317L, 321, 347, S31803 (F51), S32205 (F60), 32750 (F53), S32760 (F55), 17-7PH ( 631), 904L |

| 8. Material origin: | TISCO, POSCO, LISCO, ZPSS, Bao steel, Krupp etc |

| 9. Application: | Flexible metal hose, air duct, Gasket, tower packing, power cable & oil well, washer, packing, heat exchanger, conveyor belting |

| 10. Coil ID: | 300MM, 400mm, 500mm as per customers’ request |

| 11. Coil weight: | as per client’s requirement. |

| 12. Delivery time | Be ready for shipment within 15~20 days upon receipt PO |

| 12. Package: | Plywood boxes. ( See pictures below ) |

| 13. Certificate: | ISO, BV, SGS, Mill test certificate |

| 14. Product quality: | Good & prime |

| 15. More information: | Contact Vivian (MP/WhatsApp/Viber: 0086-13921352562) skype: vivian.316L |

2) Chemical composition:

3) Product picture display:

- Q: Are 111 stainless steel strips suitable for heat sinks?

- 111 stainless steel strips are unsuitable for heat sinks. Heat sinks are designed to effectively dissipate heat from electronic components and thus require materials with high thermal conductivity. Although stainless steel has numerous desirable properties, it lacks good thermal conductivity, particularly when compared to other metals like aluminum or copper that are commonly used for heat sinks. Consequently, it is advisable to utilize materials with higher thermal conductivity for heat sinks in order to guarantee efficient heat dissipation.

- Q: What is the corrosion resistance of stainless steel strips in different environments?

- Stainless steel strips exhibit an exceptional ability to resist corrosion in diverse environments due to the presence of a protective layer known as chromium oxide on the steel's surface. This layer forms naturally when the steel is exposed to oxygen and acts as a passive barrier, preventing further corrosion. In outdoor settings, stainless steel strips demonstrate high resistance to corrosion in atmospheric conditions. They can endure exposure to moisture, rain, and even saltwater without significant deterioration. Consequently, stainless steel is an excellent choice for marine environments and coastal areas where corrosion is a prevalent concern. Additionally, stainless steel strips possess outstanding resistance to various chemicals and acids. They can withstand exposure to a wide range of organic and inorganic compounds, making them suitable for use in corrosive environments such as chemical processing plants and pharmaceutical industries. However, it is crucial to note that certain concentrations or combinations of chemicals can still cause corrosion in stainless steel. Therefore, selecting the appropriate grade of stainless steel for specific applications is essential. The corrosion resistance of stainless steel strips can vary depending on the specific alloy and surface finish. For example, austenitic stainless steels like grades 304 and 316 offer excellent corrosion resistance in most environments, including acidic and alkaline conditions. On the other hand, ferritic and martensitic stainless steels may have slightly lower corrosion resistance but can still perform well in non-corrosive or mildly corrosive environments. In conclusion, stainless steel strips possess remarkable corrosion resistance in a wide variety of environments. Their ability to resist corrosion makes them highly versatile and suitable for diverse applications, such as construction, automotive, and food processing. However, it is crucial to consider the specific conditions and requirements of the environment when selecting the appropriate grade and finish of stainless steel to ensure optimal corrosion resistance.

- Q: Are 111 stainless steel strips suitable for chemical storage tanks?

- No, 111 stainless steel strips are not suitable for chemical storage tanks. 111 stainless steel is not specifically designed to resist corrosion or withstand the aggressive chemical environments that are typically found in storage tanks. It is important to use stainless steel grades that are specifically designed for chemical storage applications, such as 304 or 316 stainless steel, which have higher resistance to corrosion and chemical attacks.

- Q: Are stainless steel strips suitable for wastewater treatment equipment?

- Indeed, wastewater treatment equipment finds stainless steel strips to be suitable. The reason lies in the fact that stainless steel possesses remarkable resistance against corrosion, a quality that proves indispensable in applications involving wastewater treatment. Given the presence of harsh chemicals and corrosive substances, stainless steel strips can endure the corrosive nature of wastewater, thus rendering them highly suitable for utilization in equipment including tanks, pipes, and pumps. Furthermore, stainless steel also demonstrates resistance to elevated temperatures, enabling it to withstand the demanding conditions commonly encountered in wastewater treatment processes. With its durability and lengthy lifespan, stainless steel strips emerge as a dependable option for wastewater treatment equipment.

- Q: What is the impact resistance of stainless steel strips?

- Stainless steel strips have excellent impact resistance due to their inherent properties and unique manufacturing process. The impact resistance of stainless steel strips is primarily attributed to their high tensile strength and toughness. Stainless steel is an alloy composed of iron, chromium, and other elements such as nickel, molybdenum, and manganese. These elements provide stainless steel with enhanced mechanical properties, including high strength and ductility. These properties allow stainless steel strips to withstand external forces and impacts without deforming or breaking easily. Moreover, stainless steel strips undergo a process called cold rolling during their manufacturing. Cold rolling involves passing the stainless steel through a series of rollers at a low temperature, which increases its strength and hardness. This process further enhances the impact resistance of stainless steel strips. The impact resistance of stainless steel strips makes them suitable for various applications that require durability and resistance to external forces. They are commonly used in industries such as automotive, construction, aerospace, and marine, where they are exposed to harsh conditions and potential impacts. In conclusion, stainless steel strips exhibit excellent impact resistance due to their high tensile strength, toughness, and the cold rolling process they undergo during manufacture. These properties make stainless steel strips a reliable choice for applications that require resistance to external forces and impacts.

- Q: Can stainless steel strips be used for medical instruments?

- Medical instruments can indeed utilize stainless steel strips. The reason behind the popularity of stainless steel in medical instruments is its numerous advantageous properties. Its exceptional resistance to corrosion is of utmost importance in maintaining cleanliness and preventing the transmission of infections. Moreover, stainless steel showcases remarkable durability, enabling it to endure high temperatures and harsh sterilization techniques, thus rendering it an ideal choice for medical purposes. Furthermore, the non-magnetic nature of stainless steel is significant for specific medical imaging procedures. All in all, stainless steel strips are a dependable and widely employed material in the production of diverse medical instruments.

- Q: What are the factors affecting the formability of 111 stainless steel strips?

- 111 stainless steel strips can be affected by various factors: 1. The formability of the stainless steel strip is greatly influenced by its alloy composition. The presence of elements like chromium, nickel, and molybdenum in different proportions can have a significant impact. Increased amounts of certain elements can enhance the strip's ability to be shaped according to desired specifications. 2. The size of the grains within the stainless steel strip also affects its formability. Smaller grain sizes generally result in improved formability due to a more uniform and consistent material structure. 3. Mechanical properties, such as strength, ductility, and hardness, play a crucial role in determining the formability of the stainless steel strip. Strips with higher ductility are generally easier to shape without experiencing cracks or breakages. 4. The surface condition of the stainless steel strip, including roughness and cleanliness, has an impact on its formability. A smooth and clean surface reduces friction and facilitates shaping without defects. 5. The temperature at which the stainless steel strip is formed can also influence its formability. Higher temperatures soften the material, making it more malleable and easier to shape. 6. Lubrication during the forming process is crucial for improving formability. The use of lubricants reduces friction, preventing galling, scratching, or sticking during forming operations. 7. The method used to form the stainless steel strip, such as bending, stretching, or deep drawing, affects its formability. Different forming methods exert varying levels of stress and strain on the material, impacting its ability to be shaped without failure. In conclusion, a range of factors, including alloy composition, grain size, mechanical properties, surface condition, temperature, lubrication, and forming method, all contribute significantly to the formability of 111 stainless steel strips.

- Q: Are stainless steel strips resistant to oxidation?

- Yes, stainless steel strips are resistant to oxidation. This is because stainless steel is an alloy that contains chromium, which reacts with oxygen in the air to form a protective layer on the surface called chromium oxide. This layer acts as a barrier, preventing further oxidation or corrosion of the metal. As a result, stainless steel strips are highly resistant to rust and corrosion, making them ideal for applications where exposure to moisture or harsh environments is a concern.

- Q: Can stainless steel strips be used in the production of medical implants?

- Yes, stainless steel strips can be used in the production of medical implants. Stainless steel is widely used in the medical industry due to its excellent corrosion resistance, durability, and biocompatibility. It can be easily fabricated into strips, which can then be shaped and formed into various medical implant devices such as orthopedic implants, surgical instruments, and dental implants.

- Q: How do stainless steel strips perform in high-temperature environments?

- Stainless steel strips generally perform well in high-temperature environments due to their excellent heat resistance properties. They can withstand elevated temperatures without significant structural changes or loss of strength. Additionally, stainless steel strips have a low thermal expansion coefficient, allowing them to maintain dimensional stability even when exposed to extreme heat.

Send your message to us

Stainless Steel Coil /Sheet in Wuxi, China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 6 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords