Stainless Steel Coil Price in Wuxi, China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Product name:stainless steel Coil

2. Standard: ASTM,AISI,SUS,JIS,EN,DIN,BS,GB

3. Material:201,202,301,303,304,304L,305,316,316L,321,410,416,420,430 etc

4.Width:1000mm,1219mm(4feet),1250mm,1500mm,1524mm(5feet),1800mm,2200mm or we can also help the size as you require

5.Thickness: From 0.25mm to 4mm

6. Surface:NO.1, NO.2D, NO.2B, BA,NO.3, NO.4,NO.240,NO.400,Hairline,NO.8, Brushed,

7. Application:Stainless steel sheet applies to construction field, ships building

industry, petroleum & chemical industries, war and electricity

industries, food processing and medical industry, boiler heatexchanger,

machinery and hardware fields. Stainless steel sheet can be made

accordingto the customers requirements

8.Minimum order qu antity: 10 TONS

Packaging & Shipping

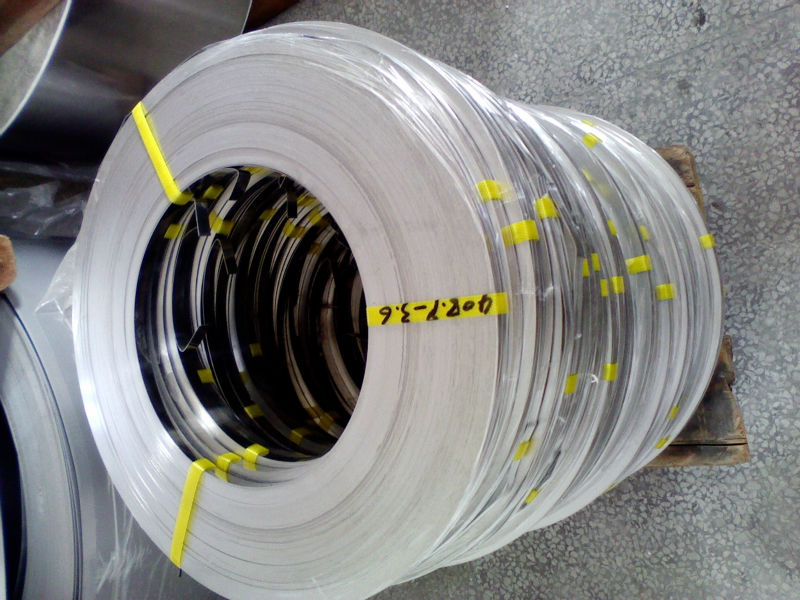

Packaging Detail: Standard seaworthy package(wooden boxes package,pvc package, and other package)

- Q: How does stainless steel strip compare to other types of metal strips?

- Stainless steel strip is known for its exceptional corrosion resistance, high strength, and durability, which sets it apart from other types of metal strips. Unlike carbon steel or aluminum strips, stainless steel strip does not easily rust or stain, even in harsh environments. This property makes it ideal for applications where exposure to moisture, chemicals, or extreme temperatures is a concern. In terms of strength, stainless steel strip is often stronger than other metal strips, allowing it to withstand heavy loads and high stress applications. It also has excellent ductility, which means it can be easily formed and shaped into various configurations without losing its structural integrity. Another advantage of stainless steel strip is its aesthetic appeal. It has a sleek and polished appearance that is often desired in architectural, decorative, and industrial applications. Additionally, stainless steel strip is easy to clean and maintain, making it a popular choice in the food processing and medical industries where hygiene is critical. While stainless steel strip does have numerous advantages, it may not be suitable for every application. It tends to be more expensive compared to other metal strips such as carbon steel or aluminum. Additionally, stainless steel strip may have lower electrical and thermal conductivity compared to copper or other metals. Ultimately, the choice of metal strip material depends on the specific requirements of the application. Stainless steel strip is a preferred choice when corrosion resistance, strength, durability, and aesthetics are of utmost importance, but it is essential to consider other factors such as cost and conductivity when making a decision.

- Q: How do stainless steel strips perform in abrasive environments?

- Stainless steel strips perform exceptionally well in abrasive environments due to their high resistance to corrosion, rust, and wear. The inherent properties of stainless steel, such as its chromium content, form a protective oxide layer that shields the material from abrasive elements. This enables stainless steel strips to withstand harsh conditions, maintain their strength, and retain their aesthetic appeal even in abrasive environments.

- Q: What is the cost of stainless steel strips compared to other materials?

- The cost of stainless steel strips can vary depending on factors such as the grade of stainless steel, the thickness and width of the strips, and the quantity being purchased. In general, stainless steel strips tend to be more expensive compared to other materials such as aluminum or carbon steel. This is primarily due to the higher cost of raw materials and the additional processing required to manufacture stainless steel. However, the durability, corrosion resistance, and aesthetic appeal of stainless steel make it a popular choice in various industries, including construction, automotive, and manufacturing. While stainless steel strips may have a higher upfront cost, they often provide long-term cost savings due to their longevity and low maintenance requirements.

- Q: What is the density of stainless steel strips?

- The density of stainless steel strips can vary depending on the specific grade and composition of the stainless steel. However, on average, stainless steel strips have a density of approximately 7.9 grams per cubic centimeter (g/cm³). This density is relatively high compared to other materials, making stainless steel strips a durable and sturdy choice for various applications in industries such as construction, automotive, and manufacturing.

- Q: What are the common uses of stainless steel strips in the kitchen?

- Due to their unique properties and benefits, stainless steel strips find widespread use in the kitchen. An example of this is their common application for kitchen countertops and backsplashes. With their resistance to stains, heat, and corrosion, stainless steel strips are chosen as a durable and hygienic option for food preparation areas. Another way stainless steel strips are commonly employed in the kitchen is for the construction of kitchen appliances. Manufacturers often utilize stainless steel strips to craft the outer surfaces of refrigerators, dishwashers, ovens, and microwaves. This choice is driven by stainless steel's ease of cleaning, resistance to fingerprints, and ability to lend a sleek and modern appearance to the appliances. Stainless steel strips are also utilized for kitchen utensils and cutlery. The robustness and corrosion resistance of stainless steel make it an ideal material for crafting knives, forks, spoons, and other cooking tools. Stainless steel utensils not only endure for a long time but also resist rust and staining, ensuring their longevity and maintaining their visual appeal. Moreover, stainless steel strips are frequently employed for kitchen sinks. Stainless steel sinks are highly sought after due to their durability, low-maintenance nature, and resistance to staining, heat, and scratches. They offer an easy-to-clean and hygienic surface for washing dishes and engaging in food preparation. In addition to these conventional uses, stainless steel strips can be used for shelving, kitchen cabinets, range hoods, and other kitchen fixtures. Overall, stainless steel strips provide numerous advantages such as durability, resistance to corrosion and heat, ease of cleaning, and an elegant appearance, making them a preferred choice for various kitchen applications.

- Q: Do stainless steel strips require any special handling or storage?

- Special handling and storage are necessary for maintaining the quality and preventing damage of stainless steel strips. Here are some important factors to consider: 1. Careful handling: It is crucial to handle stainless steel strips with caution to prevent any physical damage such as scratches or dents. To avoid contamination from oils, dirt, or fingerprints, it is recommended to wear gloves and protective equipment. 2. Proper storage: To prevent corrosion, stainless steel strips should be stored in a clean, dry, and well-ventilated area. They should be kept away from moisture, chemicals, and other substances that can cause harm. Ideally, the storage location should have controlled temperature and humidity levels. 3. Protection methods: To ensure the longevity of stainless steel strips, it is essential to protect them from contact with other metals or abrasive materials. Storing them separately or using suitable packaging, such as plastic or paper interleaved between the strips, can help prevent scratches and other damages. 4. Appropriate handling equipment: When moving or transporting stainless steel strips, it is advisable to use equipment specifically designed for handling metal products. Lifting devices, slings, or clamps can provide proper support and prevent bending or deformation of the strips. 5. Regular inspections: Regularly inspecting stainless steel strips for any signs of damage, corrosion, or deterioration is crucial. Addressing any issues promptly can prevent further degradation and ensure the quality of the strips. By adhering to these guidelines, stainless steel strips can be stored and handled correctly, maintaining their integrity and enabling their successful use in various industries.

- Q: How do stainless steel strips resist stress corrosion cracking in sulfuric acid?

- Stainless steel strips possess exceptional resistance against stress corrosion cracking in sulfuric acid due to their unique composition and properties. These strips are primarily made of iron, chromium, and nickel, along with other alloying elements. Chromium plays a vital role in providing corrosion resistance by forming a passive oxide layer on the surface of the strip, which acts as a protective barrier against corrosive environments. In the case of sulfuric acid, the presence of chromium in stainless steel strips forms a stable and continuous chromium oxide layer. This oxide layer acts as a protective shield, preventing the acid from directly coming into contact with the underlying metal. The sulfuric acid reacts with the oxide layer, forming a thin layer of metal sulfate on the surface. This layer is highly insoluble and provides an additional barrier against further corrosion. Furthermore, stainless steel strips often contain a higher concentration of nickel, which enhances their resistance to stress corrosion cracking. Nickel improves the ductility and toughness of the material, making it more resistant to the formation and propagation of cracks under stress. It also helps to maintain the integrity of the passive oxide layer, ensuring long-term protection against corrosion. Moreover, the specific composition and manufacturing processes used in the production of stainless steel strips can further enhance their resistance against corrosion. For instance, the addition of molybdenum improves their resistance to pitting and crevice corrosion, which can be particularly troublesome in sulfuric acid environments. Overall, stainless steel strips' ability to resist stress corrosion cracking in sulfuric acid is primarily attributed to the formation of a passive oxide layer, the presence of alloying elements like chromium and nickel, and additional elements like molybdenum. These factors work together to provide excellent corrosion resistance, making stainless steel strips a reliable and durable choice for applications in sulfuric acid environments.

- Q: How do you prevent stress corrosion cracking of stainless steel strips?

- To prevent stress corrosion cracking of stainless steel strips, several measures can be taken: 1. Material selection: Choose the appropriate grade of stainless steel that resists stress corrosion cracking. Austenitic stainless steels, such as 304 and 316, are commonly used due to their high resistance to corrosion. 2. Avoid exposure to corrosive environments: Ensure that the stainless steel strips are not exposed to environments containing corrosive elements such as chlorides, acids, or alkalis. This can be achieved by proper storage and handling, as well as avoiding contact with chemicals that might cause corrosion. 3. Control stress levels: Stress corrosion cracking is more likely to occur when stainless steel is subjected to tensile stress. Minimize stress levels by avoiding excessive bending, forming, or welding of the strips. Proper design and manufacturing techniques, such as using appropriate radii for bends and reducing residual stresses, can help prevent stress corrosion cracking. 4. Surface protection: Apply a protective coating or passivation treatment to the stainless steel strips to create a barrier against corrosive agents. Passivation removes surface contaminants and forms a passive oxide layer, enhancing the material's resistance to corrosion. 5. Regular maintenance and inspection: Regularly inspect the stainless steel strips for signs of corrosion or cracking. This allows early detection and corrective actions to be taken, preventing further damage and ensuring the longevity of the material. By following these preventive measures, stress corrosion cracking can be effectively minimized, ensuring the durability and performance of stainless steel strips in various applications.

- Q: Are 111 stainless steel strips suitable for desalination plants?

- Yes, 111 stainless steel strips are suitable for desalination plants.

- Q: Are stainless steel strips resistant to phosphoric acid?

- Yes, stainless steel strips are generally resistant to phosphoric acid. Stainless steel is known for its corrosion resistance due to the presence of chromium and other alloying elements. Phosphoric acid is a relatively mild acid and does not typically cause significant corrosion or damage to stainless steel. However, it is important to note that prolonged exposure to high concentrations or elevated temperatures of phosphoric acid may still cause some corrosion or pitting on the surface of stainless steel. Therefore, it is recommended to avoid prolonged or excessive contact with phosphoric acid to maintain the longevity and appearance of stainless steel strips.

Send your message to us

Stainless Steel Coil Price in Wuxi, China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords