Stainless Steel Coil Price Per Ton in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Item Details:

1, 2b cold rolled stainless steel coil with thickness 0.25~1.2mm

2, Finishing: 2B

3, Width: 15~600mm

4. Tolerance: -0.01mm~0.01mm

Our advantage

1, High quality: Using lastest automated control equipment to ensure 2b cold rolled stainless steel coil quality, such as AGC system.

2, Best Price: With most automated equipments to cost down.

3, Fast delivery: Since your order placed, ETD will be only 10 days.

4, Best Sevice: We do believe your encouragement is the best support for us.

Shipping information:

1, Payment terms: T/T 30% for depsoit, Balance against the copy of B/L; or L/C at sight

2, ETD: 10-15 days after the receipt of the deposit

3, Ship terms: FOB Ningbo

4, Minimum quantity: 5 tons

Contact and Feedback:

If you are interested in 2b cold rolled stainless steel coil or any question, please feel free to contact us. We will reply you within 24H.

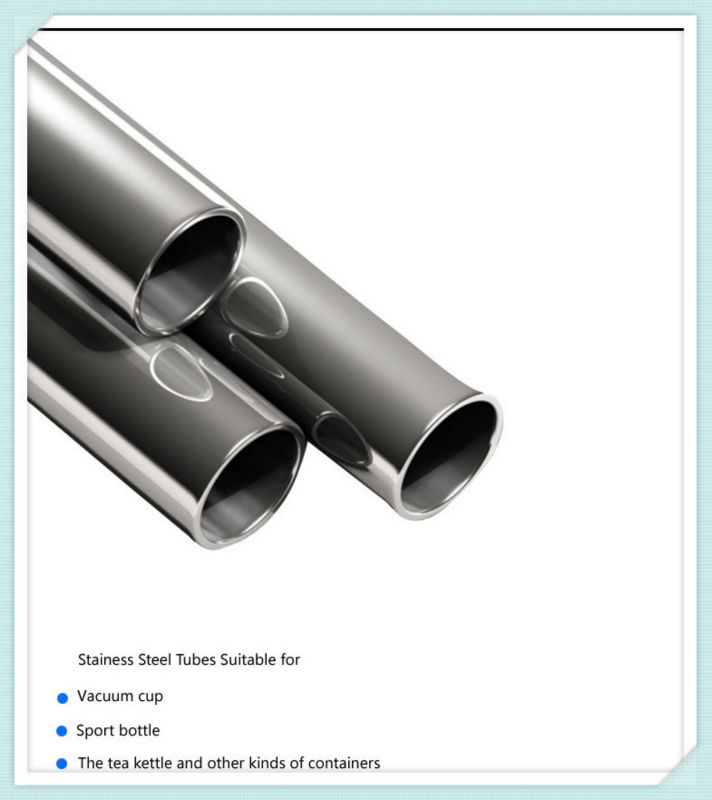

Our Main products:

We are professional manufacturer of 201, 202, 304, 304J1 an 316L stainless steel coil. With 2B finishing, width 20 to 600mm thickness 0.25mm to 1.2mm or width 600mm to 1220mm thickness 0.3mm to 1.5mm.

- Q:How do 111 stainless steel strips perform in acidic environments?

- Stainless steel is generally known for its corrosion resistance and durability, but the performance of 111 stainless steel strips in acidic environments can vary depending on the specific composition of the alloy and the concentration of the acid. In general, stainless steel grades with a higher chromium content, such as 111 stainless steel, exhibit excellent resistance to corrosion in acidic environments. The presence of chromium in stainless steel forms a passive oxide layer on the surface of the material, which acts as a protective barrier against corrosion. This oxide layer, known as the passive film, prevents the acid from reaching the underlying metal and helps maintain the integrity of the stainless steel. However, the performance of 111 stainless steel strips can be influenced by the type and concentration of acid present. Strong acids, such as hydrochloric acid or sulfuric acid, can still pose a risk to stainless steel, even with higher chromium content. The aggressive nature of these acids can lead to localized corrosion or pitting on the surface of the stainless steel. It is important to consider the specific application and concentration of the acid when using 111 stainless steel strips in acidic environments. In some cases, additional measures such as selecting a more corrosion-resistant stainless steel grade or applying protective coatings may be necessary to enhance the performance and longevity of the material. In summary, while 111 stainless steel strips generally offer good corrosion resistance in acidic environments due to their higher chromium content, the specific performance can be influenced by the type and concentration of acid present. Careful consideration of the application and potential risks is essential to ensure optimal performance and durability.

- Q:Are stainless steel strips suitable for decorative etching?

- Indeed, stainless steel strips prove to be fitting for decorative etching purposes. The versatility of stainless steel allows for the etching and engraving of elaborate and intricate designs and patterns. Its polished and smooth surface lends itself perfectly to the creation of detailed and visually captivating decorative etchings. Moreover, stainless steel exhibits exceptional durability and resistance to corrosion, ensuring the longevity of the etched designs. This quality has made stainless steel strips a favored option for a multitude of decorative applications, including signage, jewelry, art pieces, and architectural elements.

- Q:How do stainless steel strips perform in high pressure environments?

- Stainless steel strips boast exceptional performance in high-pressure environments, owing to their unique composition rich in chromium and nickel. As a result, these strips offer excellent resistance against corrosion, oxidation, and scaling, rendering them exceptionally reliable and durable even in high-pressure applications where alternative materials may falter. In environments characterized by high pressure, stainless steel strips uphold their structural integrity and dimensional stability unwaveringly. They possess the ability to withstand extreme pressure without undergoing any deformation or breakage, thereby guaranteeing system safety and efficiency. Moreover, stainless steel strips exhibit remarkable tensile strength, enabling them to endure the forces exerted by high-pressure conditions. Additionally, stainless steel strips demonstrate exceptional heat resistance, enabling them to withstand the elevated temperatures associated with high-pressure environments. They can endure thermal expansion and contraction, thereby preserving their shape and performance even amidst fluctuating temperature circumstances. In the realm of chemical resistance, stainless steel strips prove highly suitable for high-pressure environments where exposure to corrosive substances remains a concern. They exhibit remarkable resistance against acids, alkalis, and diverse chemicals, thereby preventing degradation and upholding strip performance over time. Furthermore, stainless steel strips are effortless to clean and maintain, a crucial feature in high-pressure environments where hygiene and sanitation are of utmost importance. Their non-porous nature prevents the accumulation of bacteria or other contaminants that could potentially compromise strip performance. In conclusion, stainless steel strips represent the optimal choice for high-pressure environments. Their corrosion resistance, high strength, heat resistance, and chemical resistance properties make them remarkably reliable and durable in such conditions.

- Q:Can stainless steel strips be used in the production of HVAC grilles?

- Yes, stainless steel strips can be used in the production of HVAC grilles. Stainless steel is a popular material choice for HVAC grilles due to its durability, corrosion resistance, and aesthetic appeal. The use of stainless steel strips in the production of HVAC grilles ensures that the grilles will be able to withstand the harsh conditions of heating, ventilation, and air conditioning systems without rusting or deteriorating over time. Additionally, stainless steel strips offer a sleek and modern appearance, making them an ideal choice for architectural and design purposes. Overall, stainless steel strips are a suitable and reliable option for manufacturing HVAC grilles.

- Q:Can stainless steel strips be used for medical implants?

- Yes, stainless steel strips can be used for medical implants. Stainless steel is a commonly used material in the medical field due to its excellent mechanical properties, corrosion resistance, and biocompatibility. It can be easily shaped into strips or other desired forms to meet the specific requirements of medical implants. Stainless steel strips are often used in orthopedic implants such as plates, screws, and wires, as well as in cardiovascular implants like stents and pacemakers. The material's ability to withstand sterilization processes and its long-term durability make it a suitable choice for medical implants. However, it is important to note that the specific grade of stainless steel used, as well as the design and surface finish of the strips, should be carefully considered to ensure compatibility with the human body and minimize the risk of adverse reactions or complications.

- Q:Are stainless steel strips suitable for dairy equipment?

- Yes, stainless steel strips are suitable for dairy equipment. Stainless steel is a commonly used material in the dairy industry due to its excellent corrosion resistance, hygienic properties, and durability. It is easy to clean, resistant to bacteria growth, and can withstand the harsh conditions typically found in dairy processing. Additionally, stainless steel strips can be easily formed into various shapes and sizes, making them versatile for different dairy equipment applications.

- Q:Are stainless steel strips suitable for medical applications?

- Stainless steel strips are indeed appropriate for medical purposes. They are highly favored in the medical field because of their exceptional resistance to corrosion, durability, and ease of sterilization. The notable levels of chromium found in stainless steel strips make them extremely resistant to corrosion, a crucial factor in maintaining a sterile environment for medical uses. Furthermore, stainless steel strips can endure the high temperatures and pressures typically encountered during the sterilization process. The material is also robust and long-lasting, enabling it to withstand the demands of medical procedures and equipment. In addition, stainless steel is biocompatible, ensuring that it does not react with bodily tissues or fluids, thus making it safe for implantable medical devices like surgical instruments, orthopedic implants, and prosthetics. All in all, stainless steel strips are a dependable and extensively utilized material in various medical applications due to their cleanliness, functionality, and compatibility with the human body.

- Q:What are the typical dimensions of stainless steel strips?

- The typical dimensions of stainless steel strips vary depending on the specific application, but they commonly range from 0.1mm to 6mm in thickness and 10mm to 600mm in width. The length can vary as per customer requirements or industry standards.

- Q:Can stainless steel strips be used in the construction industry?

- Yes, stainless steel strips are commonly used in the construction industry. They are versatile, durable, and resistant to corrosion, making them suitable for various applications such as structural support, cladding, roofing, and interior finishes.

- Q:What are the maximum temperatures stainless steel strips can withstand?

- The maximum temperatures stainless steel strips can withstand depend on the specific grade of stainless steel. However, in general, stainless steel can typically withstand temperatures ranging from 1200°F (649°C) to 1600°F (871°C) without significant loss of strength or corrosion resistance.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Stainless Steel Coil Price Per Ton in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords