Stainless Steel Coil Price inWuxi China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 6 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

304/310/316/430/202/201 stainless steel coil | ||

General Info | ||

Products: | Stainless Steel Coil | |

Grade: | 201/304/430/316/316L | |

Steel type: | Cold rolled or Hot rolled stainless steel | |

Thickness: | 0.3-12.0MM | |

standard size | 4'*8ft'(1219*2438mm), 4*10ft(1219*3048mm), 1000*2000mm,1500*3000 or customed size | |

Brand: | TISCO,JISCO,LISCO,BAO STEEL | |

Material Standard: | ASTM/JIS/GB/BV | |

Surface Protection: | Paper or PVC | |

Application: | Interior decoration, elveator, appliance… | |

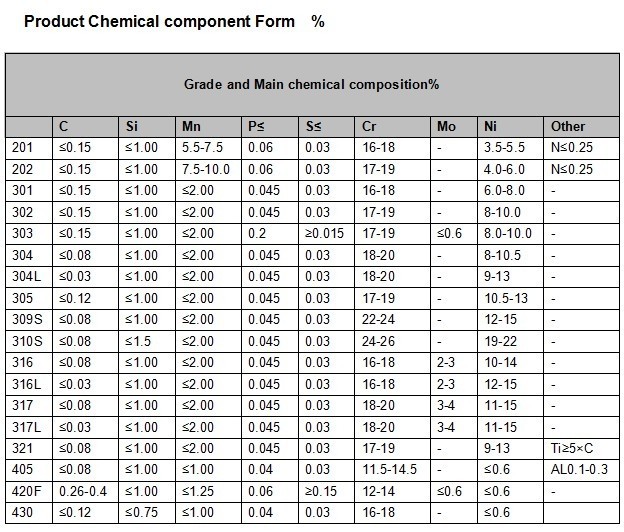

Chemical Composition

Core-competitiveness | ||

1. Leading Manufactures in the local market and exporting area | ||

2. Fast spead for the shipment with good quality and packing. | ||

3. One of the biggest stainless steel sheets stock holder in jiangsu province | ||

4.Flexible payment options such as:TT/ LC and Sale on credit for regular buyers |

Surface

| Definition | Application

|

No.1 | The surface finished by heat treatment and pickling or processes corresponding there to after hot rolling.

| Chemical tank, pipe.

|

2B(No.2B) | Those finished, after cold rolling, by heat treatment, pickling or other equivalent treatment and lastly by cold rolling to given appropriate luster.

| Medical equipment, Food industry, Construction material, Kitchen utensils.

|

NO.3

| Those finished by polishing with No.100 to No.120 abrasives specified in JIS R6001.

| Kitchen utensils, Building construction.

|

NO.4

| Those finished by polishing with No.150 to No.180 abrasives specified in JIS R6001.

| Kitchen utensils, Building construction, Medical equipment.

|

HL

| Those finished polishing so as to give continuous polishing streaks by using abrasive of suitable grain size | Building Construction. |

BA(No.6) | Those processed with bright heat treatment after cold rolling.

| Kitchen utensils, Electric equipment, Building construction.

|

Mirror(No.8) | shinning like a mirror | Building construction decoration |

Packaging & Shipping

We will packing as the factory ,and reach the stander of export . Or as the customer request.In addition,We will make the products with good surface protection.

Factory & Warehouse

- Q: What are the different types of surface finishes available for stainless steel strips?

- There are several different types of surface finishes available for stainless steel strips, each offering unique properties and aesthetic appeal. Some of the most common types include: 1. No. 1 Finish: This is a hot-rolled, annealed, and pickled finish that exhibits a rough and dull appearance. It is commonly used for applications where a rough texture is desired or for further processing. 2. No. 2B Finish: This finish is achieved by cold-rolling stainless steel strips and subsequently annealing them in a controlled atmosphere. It results in a smooth, reflective surface that is suitable for general applications requiring a bright and uniform appearance. 3. No. 2D Finish: Similar to the No. 2B finish, this surface finish is achieved by cold-rolling stainless steel strips and annealing them in a hydrogen atmosphere. It provides a slightly duller and less reflective surface compared to the No. 2B finish. 4. No. 3 Finish: Also known as a ground finish, it is achieved by mechanically polishing the surface of stainless steel strips using abrasive belts or brushes. This finish creates a semi-reflective appearance with a linear grain pattern. 5. No. 4 Finish: This is a popular finish for decorative applications, achieved through the use of polishing belts or brushes. It produces a brushed appearance with a consistent grain pattern, providing a satin-like finish. 6. No. 6 Finish: This is a high-gloss finish that is obtained through polishing stainless steel strips with successively finer abrasives. It offers a reflective and mirror-like appearance, making it suitable for decorative applications. 7. No. 7 Finish: Similar to the No. 6 finish, this is achieved by polishing stainless steel strips with successively finer abrasives. However, it is then buffed to create a highly reflective finish with enhanced clarity and depth. 8. No. 8 Finish: Often referred to as a mirror finish, this is the highest level of polish available for stainless steel strips. It is achieved through polishing with extremely fine abrasives, resulting in a flawless, highly reflective, and mirror-like surface. 9. Bead Blasting Finish: This finish is achieved by propelling small glass beads or steel shots at the surface of stainless steel strips. It creates a uniform matte appearance with a slightly rough texture. 10. Electropolished Finish: This is a specialized finish that involves the use of an electrolytic bath to remove a controlled amount of metal from the surface of stainless steel strips. It results in a smooth, bright, and clean finish with enhanced corrosion resistance. These various surface finishes offer a range of appearances and functional properties, allowing stainless steel strips to be utilized in a wide array of applications, from architectural and decorative to industrial and sanitary.

- Q: Which stainless steel belt has better elasticity?

- SUS301 is the highest hardness, can be HV590 degrees, is less than SUS304. If you want to use the materials required materials SUS301 HV480.

- Q: How do stainless steel strips resist pitting?

- Stainless steel strips resist pitting due to the presence of chromium in the alloy, which forms a passive oxide layer on the surface. This oxide layer acts as a protective barrier, preventing the penetration of corrosive agents and thus reducing the risk of pitting corrosion.

- Q: What are the benefits of using 111 stainless steel strips over other materials?

- There are several benefits of using 111 stainless steel strips over other materials. Firstly, 111 stainless steel is highly resistant to corrosion and oxidation, making it suitable for use in various environments, including ones with high humidity or exposure to chemicals. This resistance ensures that the stainless steel strips have a longer lifespan compared to other materials, reducing the need for frequent replacements and saving costs in the long run. Secondly, 111 stainless steel strips have excellent strength and durability. They can withstand heavy loads and are highly resistant to wear and tear. This makes them ideal for applications that require high strength and reliability, such as construction, automotive, and industrial sectors. Additionally, 111 stainless steel strips offer superior heat resistance. They can withstand high temperatures without losing their structural integrity, making them suitable for applications in extreme temperature conditions, such as in furnaces or industrial ovens. Furthermore, stainless steel is a hygienic material that is easy to clean and maintain. It is non-porous, preventing the growth of bacteria, making it suitable for applications in the food and medical industries. It is also resistant to staining, which ensures a clean and aesthetically pleasing appearance. Lastly, 111 stainless steel strips are versatile and can be easily fabricated into various shapes and sizes, allowing for customization to meet specific project requirements. This versatility makes them suitable for a wide range of applications, from architectural and decorative purposes to structural components. In conclusion, the benefits of using 111 stainless steel strips over other materials include corrosion resistance, strength and durability, heat resistance, hygiene, and versatility. These properties make them a preferred choice in various industries, ensuring longevity, reliability, and cost-effectiveness.

- Q: What is the melting point of stainless steel strips?

- The melting point of stainless steel strips is subject to variation based on the specific alloy employed. Typically, the melting point of stainless steel strips falls within the range of 2,500 to 2,800 degrees Fahrenheit (1,370 to 1,540 degrees Celsius). Nevertheless, it should be emphasized that dissimilar grades or compositions of stainless steel might possess marginally diverse melting points.

- Q: Can stainless steel strips be painted or coated?

- Yes, stainless steel strips can be painted or coated.

- Q: How do stainless steel strips perform in high-temperature steam?

- Stainless steel strips perform exceptionally well in high-temperature steam due to their excellent resistance to corrosion and oxidation. They exhibit high strength, durability, and stability even under extreme heat and pressure conditions, making them suitable for various applications in steam-based industries such as power generation, chemical processing, and food production.

- Q: How do you clean stainless steel strips?

- To clean stainless steel strips, you can start by wiping them down with a soft cloth or sponge soaked in warm soapy water. For tougher stains or dirt buildup, you can use a non-abrasive cleaner specifically formulated for stainless steel. It's important to avoid using abrasive materials or harsh chemicals as they can damage the surface. After cleaning, make sure to rinse the strips thoroughly with water and dry them with a clean cloth to prevent water spots or streaks.

- Q: Can 111 stainless steel strips be used in high-temperature applications?

- 111 stainless steel strips are not suitable for high-temperature applications. It is a type of stainless steel with low carbon content, commonly used for general purposes. Its maximum operating temperature is approximately 400-450 degrees Celsius (750-840 degrees Fahrenheit). To ensure adequate heat resistance and oxidation resistance at elevated temperatures, it is advisable to utilize stainless steel grades like 310, 316, or 321, which possess higher levels of chromium and nickel.

- Q: Are stainless steel strips heat resistant?

- Yes, stainless steel strips are heat resistant. Stainless steel is known for its ability to withstand high temperatures without deformation or damage. It has a high melting point and can retain its strength even at elevated temperatures. This makes stainless steel strips suitable for various applications that involve exposure to heat, such as in industrial processes, cooking utensils, and automotive components. Stainless steel's heat resistance also contributes to its durability and longevity, as it can withstand thermal stress and maintain its structural integrity over time.

Send your message to us

Stainless Steel Coil Price inWuxi China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 6 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords