Stainless Steel Coil Price in Wuxi China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specifications about stainless steel coils

Item Name | Stainless steel coils |

Grade Steel | 201/202/301/304/304L/310S/316/316L/316Ti/321/410/420 |

Technique | old Rolled, Cold Drawn, Hot Rolled |

Brand | TISCO,BAOSTEEL,LISCO,JISCO,ZPSS,POSCO |

Standard | ASTM,AISI,JIS,GB,DIN,EN |

Thickness | 0.3mm-100mm or as your requirement |

Width | 100mm-3000mm or as your requirement |

Length | 1000mm-10000mm or as your requirement |

Surface Treatment | BA,2B,No.1,No.4,No.8,HL,8K,Brush,Mirror,Polish ect |

Packing | 1.Export sea worthy package + water proof paper + wooden pallet 2. Max Loading 26.5mt for each 20Gp container 3.Safe loading and fixing Professiona teams 4. Professional shipping line |

MOQ | 1 TON |

Delivery | 5 days after received the 30% deposit of T/T or L/C |

Payment | T/T,30%payment in advance,70%T/T after the copy of B/L or L/c at sight |

Application | Stainless Steel Sheets are widely used in below fields: 1: Construction field, shipping building industry 2: Petroleum and Chemical Industries 3: Food and Mechanical Industries |

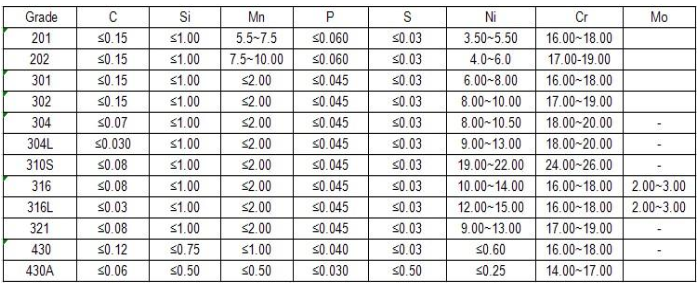

2. Chemical Composition about stainless steel coils

3. Surface--stainless steel coils

Surface Finish | Definition | Application |

2B | Those finished, after cold rolling, by heat treatment, pickling or other equivalent treatment and lastly by cold rolling to given appropriate luster. | Medical equipment, Food industry, Construction material, Kitchen utensils. |

BA | Those processed with bright heat treatment after cold rolling. | Kitchen utensils, Electric equipment, Building construction. |

NO.3 | Those finished by polishing with No.100 to No.120 abrasives specified in JIS R6001. | Kitchen utensils, Building construction. |

NO.4 | Those finished by polishing with No.150 to No.180 abrasives specified in JIS R6001. | Kitchen utensils, Building construction, Medical equipment. |

HL | Those finished polishing so as to give continuous polishing streaks by using abrasive of suitable grain size. | Building Construction. |

NO.1 | The surface finished by heat treatment and pickling or processes corresponding there to after hot rolling. | Chemical tank, pipe |

4.Product Photos

Packaging & Shipping

5.Packaging--stainless steel coils

Our Services

6.Manufacturing Process of Stainless Steel Sheet/Plate:

Raw materials are sending to hot rolling units for rolling into different sizes.

→Hot rolled material is annealing in cold rolled annealing furnace and pickling in acid.

→All mill rolls are grinded on precision grinding machine with proper chamfering after first shift operation.

→All sheets are pickled in different tanks and dried on brush roll machine before dispatched.

→These sheets are again annealing and are sent to straighten machine for straightening.

→Inspections are done at various stages. Keep proper control overall internal process via rolling, annealing and pickling by our experienced staff.

8.Application--stainless steel sheet/plate

Stainless steels of various kinds are used in thousands of applications. The following gives a flavour of the full range:

1.Domestic – cutlery, sinks, saucepans, washing machine drums, microwave oven liners, razor blades

2.Transport – exhaust systems, car trim/grilles, road tankers, ship containers, ships chemical tankers, refuse vehicles

3.Oil and Gas – platform accommodation, cable trays, subsea pipelines.

4.Medical – Surgical instruments, surgical implants, MRI scanners.

5.Food and Drink – Catering equipment, brewing, distilling, food processing.

6.Water – Water and sewage treatment, water tubing, hot water tanks.

7.General – springs, fasteners (bolts, nuts and washers), wire.

8.Chemical/Pharmaceutical – pressure vessels, process piping.

9.Architectural/Civil Engineering – cladding, handrails, door and window fittings, street furniture, structural sections,reinforcement bar, lighting columns, lintels, masonry supports

- Q: Can stainless steel strips be used in chemical processing?

- Indeed, chemical processing can incorporate stainless steel strips. Renowned for its impressive resistance to corrosion, stainless steel proves to be an ideal material for a multitude of applications within the chemical industry. With its ability to withstand a wide range of aggressive chemicals, acids, and bases, as well as its capacity to endure high temperatures and pressures, stainless steel emerges as a commonly utilized component in chemical processing machinery, including reactors, heat exchangers, storage tanks, and piping systems. Offering durability, dependability, and an extensive lifespan, stainless steel strips are the favored choice for handling corrosive chemicals and upholding product purity during chemical processing operations.

- Q: What are the common thickness tolerances for stainless steel strips?

- The common thickness tolerances for stainless steel strips can vary depending on the specific industry standards and requirements. However, in general, the common thickness tolerances for stainless steel strips range from ±0.0015 inches to ±0.005 inches. These tolerances ensure that the stainless steel strips meet the desired thickness specifications and maintain consistent quality throughout the manufacturing process. It is important to note that these tolerances may vary depending on the specific grade of stainless steel and the intended application of the strips. Manufacturers and customers often communicate and agree upon the specific tolerances needed to meet their unique requirements.

- Q: What are the recommended storage and transportation conditions for 111 stainless steel strips?

- The recommended storage and transportation conditions for 111 stainless steel strips include keeping them in a clean and dry environment to prevent corrosion. It is advisable to store them in a covered area that is well-ventilated and free from moisture and excessive humidity. The strips should be stored in a horizontal position to prevent warping or bending. Additionally, it is important to protect the strips from exposure to chemicals, acids, and other corrosive substances. During transportation, the strips should be packaged securely using appropriate materials such as wooden crates or cardboard boxes. They should be properly wrapped or padded to prevent damage from vibration or impact during transit. It is also recommended to use moisture-resistant packaging to prevent any moisture absorption during transportation. Following these recommended storage and transportation conditions will help ensure the quality and integrity of the 111 stainless steel strips.

- Q: What are the typical hardness values of stainless steel strips?

- The typical hardness values of stainless steel strips can vary depending on the specific grade and type of stainless steel being used. However, stainless steel strips generally have a hardness range between 150 and 250 on the Vickers hardness scale (HV). Some grades of stainless steel may have higher hardness values, reaching up to 300 HV or more, while others may have lower hardness values, closer to the lower end of the range. It is important to note that the hardness of stainless steel strips can also be influenced by factors such as the heat treatment process and the thickness of the strip.

- Q: How do stainless steel strips perform in corrosive marine environments?

- Stainless steel strips perform exceptionally well in corrosive marine environments due to their inherent resistance to corrosion. The chromium content in stainless steel forms a passive protective layer, preventing the strips from rusting and maintaining their structural integrity even in highly corrosive conditions.

- Q: What are the different thicknesses available for stainless steel strips?

- Stainless steel strips are available in various thicknesses to suit different applications and requirements. Typically, the thickness options for stainless steel strips range from 0.0015 inches (0.0381 mm) to 0.125 inches (3.175 mm) or even thicker, depending on the specific project needs. These thicknesses are commonly measured in gauge, with 22 gauge (0.030 inches) and 16 gauge (0.0625 inches) being the most prevalent. Nonetheless, it should be noted that stainless steel strips can be tailored to meet specific thickness requirements if necessary. The choice of thickness will be influenced by factors such as the intended usage of the strips, the desired level of durability and strength, and any applicable industry standards or regulations that must be adhered to.

- Q: What are the common uses of stainless steel strips in the pharmaceutical industry?

- Stainless steel strips are commonly used in the pharmaceutical industry for various purposes such as constructing equipment and machinery, manufacturing packaging materials, and ensuring hygiene and cleanliness in the production process. They are also utilized in the fabrication of storage and transportation containers, as well as in the construction of cleanrooms and controlled environments. Overall, stainless steel strips serve as a versatile and reliable material that meets the stringent requirements of the pharmaceutical industry.

- Q: What is the coefficient of thermal expansion of stainless steel strips?

- The coefficient of thermal expansion of stainless steel strips typically ranges between 10-17 x 10^-6 per degree Celsius.

- Q: How do stainless steel strips resist stress corrosion cracking in chloride environments?

- Stainless steel strips are highly resistant to stress corrosion cracking in chloride environments due to their inherent properties and specific alloy composition. The primary factors that contribute to this resistance include the presence of chromium, molybdenum, and nickel in the stainless steel alloy. Chromium is the main component responsible for the corrosion resistance of stainless steel. When exposed to chloride ions in the environment, a passive oxide layer of chromium oxide forms on the surface of the stainless steel strips. This oxide layer acts as a protective barrier, preventing the penetration of chloride ions and reducing the likelihood of stress corrosion cracking. Molybdenum is another crucial element in stainless steel alloys that enhances their resistance to stress corrosion cracking in chloride environments. It provides additional protection by increasing the material's resistance to pitting and crevice corrosion, which can be precursors to stress corrosion cracking. The presence of molybdenum also improves the overall strength and durability of the stainless steel strips. Nickel is an alloying element that further enhances the resistance of stainless steel strips to stress corrosion cracking. It increases the material's ability to withstand the corrosive effects of chloride ions, thereby minimizing the risk of crack initiation and propagation. In addition to these alloying elements, the specific composition and microstructure of the stainless steel strips play a crucial role in their resistance to stress corrosion cracking. The selection of an appropriate stainless steel grade, such as 316 or 904L, with a higher content of chromium, molybdenum, and nickel, ensures optimal resistance to chloride-induced corrosion. Furthermore, proper fabrication processes and surface treatments, such as passivation, can help enhance the corrosion resistance of stainless steel strips in chloride environments. Passivation involves the removal of iron contaminants from the surface and the formation of a more uniform and protective chromium oxide layer, further reducing the risk of stress corrosion cracking. Overall, stainless steel strips resist stress corrosion cracking in chloride environments due to the synergistic effects of chromium, molybdenum, and nickel, as well as their specific alloy composition, microstructure, and surface treatments. These factors collectively contribute to the exceptional corrosion resistance of stainless steel, making it a preferred choice for various industries, including marine, chemical, and oil and gas.

- Q: Can stainless steel strips be used in harsh weather conditions?

- Stainless steel strips are capable of withstanding even the harshest weather conditions. Renowned for its outstanding resistance to corrosion, stainless steel is highly impervious to rust and other forms of deterioration caused by exposure to moisture, humidity, and extreme temperatures. Consequently, stainless steel strips prove to be a dependable and long-lasting choice for various applications that experience adverse weather, such as outdoor structures, building facades, roofing, and marine environments. The corrosion resistance of stainless steel can be attributed to the presence of chromium within its composition, which creates a protective layer on the metal's surface, preventing it from reacting with the surrounding environment. Moreover, stainless steel also possesses resistance to UV radiation and can endure strong winds, making it a suitable option for regions prone to storms and hurricanes. In conclusion, stainless steel strips offer an outstanding solution for applications that necessitate strength, durability, and the ability to withstand harsh weather conditions.

Send your message to us

Stainless Steel Coil Price in Wuxi China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords