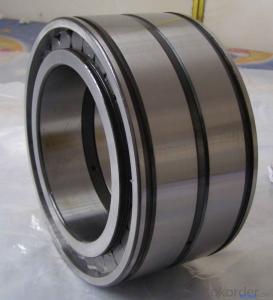

self-lubricated sliding bearing with high quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

self-lubricated sliding bearing

1, low wear, low friction , with long life

2,low vibration, low noise and non-pollution

self-lubricated sliding bearing

Material

1.PTFE with fibre 0.01~0.03mm

2.Porous bronze 0.2~0.3mm

3.Steel backing 0.7~2.3mm

4.Tin-plating 0.005mm or copper plating 0.008mm

Technical

Load capacity 140N/mm2

Temperature -195°C ~ +280°C

Speed limit 5m/s

Friction coef(u) 0.04~0.20

PV Limit(Dry) 3.6N/mm2 .m/s

Application

1.PTFE and fibre can protect the shaft while in operation.

2.It is suitable for the machine required harmless to people because

of Lead-free.

3.Goodload capacity and anti-wear.

4.Bronze and steel have good thermal conductivity.

5.Anti-corrosion because of surface plating.

6.It is widely used in general machines,and suitable for food machine,pharmaceutical

machine,tobacco machine etc.It will subsitute SF-1 series bushings in future because of environment protection.

- Q: The unit has to take out a review question and answer questionHow should emergency handling of engine pump sliding bearings cause heating and smoke?Who knows how to answer one of the troubles?,Then ask a question, generally speaking, sliding bearings, heating, smoke, what are the ways to deal with it, there are known to say, I sum up, good answer

- Brother, I did 14 years of mechanical maintenance, sliding bearings, heating, smoke, the most urgent treatment: 1. emergency shutdown. The sliding bearing heating smoke indicates that the clearance between the sliding bearing and the shaft is too tight, or that the grease / grease has impurities (metal scraps) and other things, and that it may be that the bearings have reached the service life and damaged. Maintenance may cause damage to the shaft if it is not shut down, so maintenance costs will be higher. 2. disassemble and repair the pump. Check what causes heat, smoke, cooling is a temporary solution, not only the pump will also heat, and may damage the whole pump. For example, check the running of the bearings, whether there is a deep scratch, or whether the shaft is worn, whether there is a foreign body. After confirming the cause, proceed "the right remedy"".

- Q: Why are the bearings rolling separately?

- According to the number of rolling columns, it is divided into single row bearings, double row bearings and multi row bearings.According to its components (rings) can be divided into separable bearings and non separable bearings.According to its structural shape (if there is no loading groove, whether there are inner, outer ring and ring shape, edge structure, or even cage, etc.), it can be divided into a variety of structural types.According to the diameter size divided into miniature bearings (<26mm), small bearings (28-55mm), small and medium-sized bearings (60-115), large bearing (120-190mm), large bearing (200-430mm) and oversize bearing (>440mm).According to the application field, it is divided into motor bearings, mill bearings, main bearings and so on.According to the material is divided into ceramic bearings, plastic bearings, etc..

- Q: How many kinds of bearings are there in sliding bearings? What's the function of each?

- 1, the gap between bearings and bearings. 2, bearings radial series gapThe first kind of clearance will cause the bearing or bush to be damaged, and the lubrication oil pressure will be reduced. The gap is too small, which will make the bearing or bearing load increase sharply and even burn (tile)The second kind of clearance is too big, the bearing will move back and forth in the radial direction, the whole machine is not stable, the gap is too small, so that the load of the machine increases

- Q: Which one is good for sliding bearings?

- Our company has perfect product research and development system, designed and developed a number of new products and patents.

- Q: Sliding bearings relative clearance 0.001 what?

- The so-called relative clearance, refers to the sliding bearings of the Bush and bushings, nominal size tolerances can be large or small, but the gap between each other can only be 0.001.

- Q: Is the bushing or roller in the sliding bearing? TwentyIs the bush or roller in the plain bearing? How do I search the "sliding bearing" in the Baidu picture, and some of the sliding bearings also have cylindrical roller, which is not cylindrical roller bearings?

- Therefore, it is essential to know the base oil viscosity at the operating temperature. The manufacturer usually specifies the use of some kind of grease, and most of the scale grease can be used in a wide range. The following is a number of important factors in selecting grease: - Mechanical variety - working conditions, such as vibration and axis horizontal or vertical - bearing type and size - temperature - cooling case - work load - sealing effect - speed range of peripheral equipment - machine environment if you want to play to the best condition of bearing must be to work properly, and prevent the high temperature, moist and polluted environment. Lubrication and covering the appropriate plan, and bearing condition monitoring is the key to play the long-life bearing. When the bearing is damaged, it may cause unexpected equipment to stop. Even an hour of downtime, because the bearing in advance, may cause great loss of production. In order to ensure the healthy operation of the equipment, in addition to relying on high-quality bearings, but also pay attention to operating environment, proper installation and regular protection.

- Q: What structure does the radial sliding bearing adopt?

- The structure of radial sliding bearings is divided into two kinds:1, integralIt consists of a bearing block, a shaft sleeve or a bearing bush. The utility model has the advantages of simple structure and low cost, but the gap caused by abrasion can not be adjusted and can only be loaded and unloaded along the axial direction.

- Q: What is the clearance ratio between the plain bearing and the shaft?

- You have to make sure you use the sliding bearing in what occasions, and then open the "mechanical design manual" volume second, find the bearing this post, there is the bearing and shaft in different occasions with the axis of tolerance, then as long as the "mechanical design manual" the first volume to check the corresponding numerical OK. It's simple

- Q: The sliding bearing consists of several parts. What are the parts?

- I understand that the so-called slip is the relative motion of the two contact surfaces. The contact surface can be flat, spherical, or otherwise.

- Q: For sliding bearing, bearings, bushings, bushing and difference function

- The bushing is mounted on the shaft, with the shaft to rotate together. The Bush is mounted on the seat and does not rotate.There are many large shaft to achieve part of high hardness and high wear resistance with the invention and bearing bushes, but since a high frequency quenching and surface treatment process after these basically eliminated.

Send your message to us

self-lubricated sliding bearing with high quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords