Bearing Bearings 7017 Angular contact ball bearings 7017 Angular contact ball bearing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 500000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Sepcification:

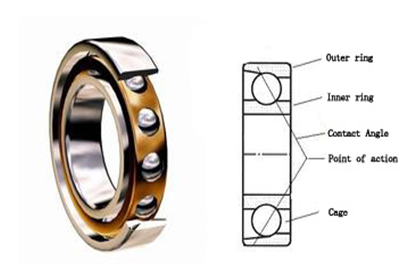

Angular contact ball bearings can bear radial load and axial load at the same time and also can bear pure axial load. Their ability of axial load is determined by contact angle and is increased with contact angle increasing; speed limit is higher; stiffness is big and can be pre-adjusted. They are applicable to high-speed and high-precision site.

Product application:

- spindle and other high speed precision mechanical spindle

- aircraft engine spindle

- high frequency motor

- printing machinery

- air compressor

- gas turbine

- jet engines

- turbines

-pump

| Design ations | Principal dimensions (mm) | 〆15º | 〆25º | ||||

| Limit speed | Limit speed | ||||||

| d | D | B | Basic load rating | Lubrication | Rated load | Lubrication | |

| Cr Cor | Grease Oil | Cr Cor | Grease Oil | ||||

| 70 Series single angular contact ball bearings | |||||||

| 7003 | 17 | 35 | 10 | 6.7 4.9 | 44000 66000 | 6.4 4.7 | 39000 59000 |

| 7004 | 20 | 42 | 12 | 9.6 6.3 | 37000 55000 | 9.2 6.0 | 33000 49000 |

| 7005 | 25 | 47 | 12 | 12.9 8.7 | 33000 49000 | 12.3 | 29000 44000 |

| 7006 | 30 | 55 | 13 | 15.7 11.6 | 27000 42000 | 14.9 10.9 | 23000 37000 |

| 7007 | 35 | 62 | 14 | 19.3 17.5 | 19000 33000 | 10.4 10.3 | 19000 33000 |

| 7008 | 40 | 68 | 15 | 19.9 19.1 | 18000 31000 | 18.9 18.2 | 16000 27000 |

| 7009 | 45 | 75 | 16 | 26.7 25.3 | 16000 27000 | 25.4 24.1 | 15000 25000 |

| 7010 | 50 | 80 | 16 | 27.6 27.5 | 15000 25000 | 26.2 26.2 | 14000 23000 |

| 7011 | 55 | 90 | 18 | 36.7 37.1 | 13000 21000 | 34.8 35.3 | 12000 19000 |

| 7012 | 60 | 95 | 18 | 37.8 | 13000 21000 | 35.8 38.0 | 11000 18000 |

| 7013 | 65 | 100 | 18 | 38.9 42.9 | 12000 19000 | 36.8 40.7 | 10000 17000 |

| 7014 | 70 | 110 | 20 | 49.9 55.5 | 11000 18000 | 47.2 52.7 | 9000 16000 |

| 7015 | 75 | 115 | 20 | 51.3 59.2 | 10000 17000 | 48.5 56.2 | 8500 15000 |

| 7016 | 80 | 125 | 22 | 61.6 70.4 | 9000 16000 | 58.3 66.9 | 8000 14000 |

| 7017 | 85 | 130 | 22 | 63.6 | 8500 15000 | 59.9 71.3 | 7500 13000 |

| 7018 | 90 | 140 | 24 | 66.9 | 8000 14000 | 63.2 79.7 | 7000 12000 |

| 7019 | 95 | 145 | 24 | 79.1 97.6 | 7500 13000 | 74.8 | 6500 11000 |

| 7020 | 100 | 150 | 24 | 81.2 103.3 | 7000 12000 | 76.7 | 6000 10000 |

| 7021 | 105 | 160 | 26 | 93.9 118.2 | 6500 11000 | 88.8 | 6000 10000 |

| 7022 | 110 | 170 | 28 | 110.4 139.8 | 6000 10000 | 104.4 132.8 | 5700 9000 |

| 7024 | 120 | 180 | 28 | 112.7 148.7 | 6000 10000 | 106.3 141.1 | 5700 9000 |

| 7026 | 130 | 200 | 33 | 144.8 190.8 | 5700 9000 | 136.8 181.0 | 5000 8000 |

| 7028 | 140 | 210 | 33 | 148.7 202.6 | 5000 8000 | 140.4 192.2 | 4600 7500 |

| 7030 | 150 | 225 | 35 | 168.4 232.5 | 4600 7500 | 159.1 220.6 | 4000 6500 |

| 7032 | 160 | 240 | 38 | 189.1 264.5 | 4000 6500 | 178.6 251.0 | 3800 6000 |

| 7034 | 170 | 260 | 42 | 205.6 299.3 | 3800 6000 | 194.2 284.0 | 3300 5300 |

| 7036 | 180 | 280 | 46 | 229.5 352.1 | 3500 5700 | 216.8 334.1 | 3000 5000 |

- Q: One hundred and twentyAttention is the reason and purpose, the postgraduate entrance examination urgent need, thank you answer, after the exam will be re points, thank you!

- If the average temperature of the oil exceeds the value set when calculating the carrying capacity, then the bearing capacity will decline or even fail, so the thermal balance calculation of the sliding bearing must be carried out.

- Q: Material and allowable line speed of plain bearings?

- Bushings in oil lubrication and oil-free lubrication, large load, and load hours allowed line speed is not the same. As the first floor said, the design of such bearings, not only depends on the V value (line speed), but also depends on the P value (load), and the PV value. Generally, the wire speed of copper alloy is about 0.5M/S.

- Q: When calculating non liquid friction sliding bearings, what is the purpose of checking P, PV, v?

- Because for non liquid friction sliding bearings, in order to make the bearing area fully lubricated, sometimes it is better to sacrifice part of the bearing area, and extend the oil tank to or directly into the load area.

- Q: Establishment of oil film bearing capacity of dynamic sliding bearing and several conditions to ensure full liquid lubrication

- Establish three conditions: relative speed, reasonable wedge, adequate lubrication. This is a necessary condition.

- Q: What are the ways to flush bearings?

- 2. shaft and bearing housings, holes and other parts of the cleaning, first with gasoline or kerosene cleaning, dry cloth clean, and then coated with a small amount of oil in order to install. These parts after cleaning, should pay attention to where the casting sand is to completely remove all burrs and sharp edges; bearing parts, must be removed, to avoid residual sand and metal debris when installed into the inner part of the bearing, affecting the quality of assembly. 1., attention to the internal, outer ring separable bearings, do not change the outer ring each other wrong, so as not to affect the quality of contact. On the ball and roller bearings, roller bearings shall be arbitrarily put out in the mix, so as not to affect the accuracy of the installation position. When installing the bearing, in order to easily observe the bearing code number, not to be wrong, the bearing rings should be typed outside and installed. The shell hole 2. bearing and bearing seat heating for a large amount of surplus and large bearing, in order to facilitate the installation, must be installed before heating; for light metal bearing shell hole tight fit (such as aluminum bearing), due to very low hardness, surface to prevent bearing outer ring press bearing shell hole the scratch and galling, should also be heating installation. Heating method, usually bearing or separate bearing ring into the tank with clean oil, so that oil flooded bearings, uniform heating. When the temperature reaches 80 - 90 degrees, remove the heat and install it while the heat is hot. The tank made available 2 3mm thick plate, from the bottom 50 70mm height with a porous plate, bearing in porous plate heating. The aim is to prevent the precipitation of impurities in the oil into the bearings. However, for both bearings with a dust cover or seal ring, the lubricant cannot be heated at the beginning of the installation because of the lubricant used in the manufacture.

- Q: What are the methods of casting plain bearings?

- According to the actual conditions: sand casting, centrifugal casting, casting bar material. There are usually special requirements, such as aircraft use, the use of super large engines, will be based on the use of the effect of casting process. Usually to the metal materials company purchased bearings, bearing bronze (or called Babbitt), many are scrap copper, the use of crucibles, casting sand.

- Q: 250 kilowatts of motors, replacement of new bearings, after driving bearing fever, the bearings inside the grease all thrown out What's the matter? Expert answer!

- I think there may be three reasons1 may make you grease too much2 may be higher bearing temperature, more than the upper limit of the grease, the use of temperature caused oxidation deterioration of the oil, it is recommended to replace high temperature grease...3, you may use the brand of grease is not correct, change cone penetration of grease is betterIn addition, the consistency of grease and temperature are also related, in general, the higher the temperature, the thicker the grease

- Q: Is it good for rolling bearings of single cylinder diesel engines or for sliding bearings?

- sliding bearing can be conveniently and the diesel engine oil lubrication system integrated with lubrication oil through the transmission oil inside the cylinder body.

- Q: What are the technical requirements and precautions for the assembly of plain bearings?

- When the shaft rotates at a high speed, the shaft to the bearing with periodically varying load, sometimes accompanied by shock.

- Q: What are the lubrication methods of plain bearings?

- Many types of sliding bearing, manufacturing materials, credit conditions and the important degree of difference, so the lubricant requirements vary, the Chongqing auto parts of sliding bearings commonly used lubricants are briefly reviewed. (1) lubricating oil. Lubricating oil is the most widely used lubricant in sliding bearings, and most of the lubricants currently used are mineral oils. The main indexes of lubricating oil are viscosity, oiliness, extreme pressure, chemical stability, etc. when selecting lubricating oil, speed, load and working condition should be taken into account. For large load, high temperature bearings, it is better to choose lubricating oil with high viscosity, small load and high speed bearing, it is better to choose less viscous lubricating oil. (2) grease. Grease is a mixture of lubricating oils and various thickening agents (such as calcium, sodium, aluminum and other metal soaps). Grease is used to form a film that separates the sliding surface. Grease seal is simple, do not need to add often, not easy to drain. But grease is easy to change, friction loss, no cooling effect, it is often used for those who are not demanding, difficult to often oil, or low speed, heavy load and not often used.

Send your message to us

Bearing Bearings 7017 Angular contact ball bearings 7017 Angular contact ball bearing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 500000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords