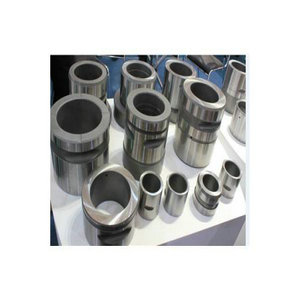

Hydraulic Cylinder bushing of chinese manufacturer

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Hydraulic Cylinder bushing (SF-1D)

1.steel backing,sintered porous bronze,PTFE layer

2.oilless,self-lubricating

3.low wear

Hydraulic Cylinder bushing (SF-1D) introduction:

1. Hydraulic special bearings is a new type op material, which in basis of SF-1P and designed in principles of oil and shock absorber. it become more wear-resisting under breaking off the lubricating oil .these products also particularly suitable for the frequent reciprocating motion besides having the advantages of SF-1P.

2. Its properties is similar to that of the foreign product designated as DP4,Currently the product gradually replace SF-1P,applying to auto shock absorber, hydraulic cylinders and other various fields.

Load capacity 120N/mm2

Max Speed 2m/s

Friction Coefficient 0.04~0.20

PV Limit (dry) 3.6N/mm2 m/s

PV Limti (oil) 50N/mm2 m/s

Temperature Limit -195oC ~+270oC

Why use Cast brass Bearing?

long service life and maintenance-free

High load capacity

High wear resistence

low coefficients of friction

Good heat conductivity

High corrosion resistence

- Q: Sliding bearings can be used for structural requirements on opposite occasions

- A) the types and characteristics of sliding bearing sliding bearing according to the 1. loads are divided into: (1) sliding bearings (radial sliding bearing); mainly bear radial load; (2) the thrust bearing, main bearing axial load. 2. sliding bearings are suitable for low speed, high precision, heavy load and structural requirements. It is also used at low speed and impact.

- Q: Maintenance method of plain bearing

- Bearing repair, installation quality is not high, 1, improve installation quality, reduce bearing vibration2, to prevent partial load and overload3 、 adopt suitable Babbitt and new bearing structure4, strictly control the bearing temperature riseBecause the grease dirt nap of large particles into the bearing gap, and embedded in the bearing bushings, bearing and shaft neck (or thrust plate) contact, hard callus formation on the surface, it will seriously scratch the shaft, bearing oil picking attention clean, especially in maintenance, should pay attention to the metal chips or clean dirtWear and tear due to impurities in the lubricating oil, foreign matter and dirt.

- Q: Factors determining the stability of plain bearings

- 2. in the working conditions of heavy load or impact load, the big oil, the viscosity of the lubricating oil, the lubricating film forming stable; 3. static or dynamic static pressure sliding bearing lubrication can be selected the oil viscosity is small; the 4. surface roughness or surface without running should choose the lubricating oil with high viscosity. Sliding bearing grease shaft speed less than 1m/s~2m/s can be used to grease, grease is agent with mineral oil, all kinds of thick (such as calcium, sodium, lithium, aluminum and other metal soap) and water to reconcile, grease consistency (penetration), large bearing capacity, but the physical and chemical property is not stable, should not be used in large temperature variation conditions for low speed and heavy load or the swing bearing. Solid lubricants and gas lubricants, solid lubricants are graphite, molybdenum disulfide (MoS2) and PTFE (PTFE) and other varieties. Usually used under heavy loads or under high temperature conditions. A gas lubricant, usually air, used for high speed and lubricating or grease free applications. Method to provide lubrication bearing lubricant is a necessary condition for the formation of the lubricating film, hydrostatic bearing and bearing through the oil pump, the throttle and the bearing oil groove to continuous supply of sliding bearing, the formation of oil film bearing and shaft neck surface makes separate.

- Q: How does a sliding bearing move at work?

- Plain bearings work smoothly, reliably and without noise. Under the condition of liquid lubrication, the sliding surface is separated by the lubricant without direct contact, and the friction loss and surface wear can be greatly reduced. The oil film also has a certain vibration absorption capacity. But the starting friction resistance is larger. The shaft supported by the bearing is called the journal, and the part that matches the journal is called the bush.

- Q: How to determine the axial clearance and expansion clearance of plain bearings?

- Hello, these are the coordination, generally refers to the hole and shaft coordination.1. "fit" refers to the relation of the same size, the combination of holes and the tolerance zone of the shaft. According to the requirements of the use of different, the hole and shaft between the coordination of loose and tight, the national standard provides that there are three categories: gap fit, interference fit and transition coordination.

- Q: What are the differences between rolling bearings and plain bearings?

- Two, compared with the sliding bearing, deep groove ball bearings shortcomings:1, vibration and noise;2. Radial dimensions larger than plain bearings;3 、 poor ability to withstand impact loading;4 、 under high speed and heavy load, the bearing life is low.

- Q: What are the commonly used sliding bearing bushing materials

- (1) grey cast iron. It is used in low speed, light load and no impact load. HT15-33 and HT20-40 are often used.(2) steel base bearing alloy. ZQSn10-1 bronze and ZQA19-4 aluminum bronze are commonly used, suitable for medium speed, high turbidity and impact loading.

- Q: Deep groove ball bearings are better than plain bearings Which one is better?

- Advantages and disadvantages of deep groove ball bearings and plain bearingsThe bearing capacity of deep groove ball bearings is not as good as that of Rongchang plain bearings, and the bearing capacity of sliding bearings is highDeep groove ball bearings, temperature Rongchang plain bearings, sliding bearings, high temperature resistance.

- Q: The difference between rolling bearings and plain bearings in ball mill

- But according to my personal inference, establishes first should be the production process - rotary grinding method, then in order to solve the problem of rotary bearing will lead to bearing hollow ball mill, but at the time of the machining level and the production process of hollow bearing cooling considerations, and ultimately selected the sliding bearing. This inference is based on technological transformation and upgrading as a clue. So it's for reference only. Secondly, compare the advantages and disadvantages of bearing and bearing the problem itself is wrong, bearing and bearing you concept is not clear, take the two kinds of commonly used ball mill bearing is divided into sliding bearing and rolling bearing, what you said is referred to as sliding bearing bush (or known).

- Q: In the design of imperfect liquid lubricated sliding bearings, what should be done to check the bearings?

- PV is the product of a certain bearing and bearing in line speed conditions and the PV value is inversely proportional to the service life of the bearing;

Send your message to us

Hydraulic Cylinder bushing of chinese manufacturer

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords