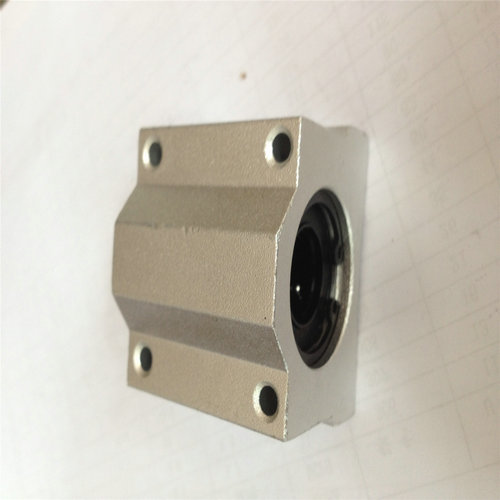

slide bearing absorber bushing plain bearing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specifications

plain bearing, slide bearing, absorber bushing

1.Good load capacity and anti-wear.

2.Widely used in the Lead-free field.

Plain bearing, slide bearing, absorber bushing

We CHANGSHEG BEARING is a direct manufacturer specialized in producing bushings with more than 10 years . We believe that we can provide you the best products and services!

du bush, pump bush, shock absorber bushings

| Max.Load | Static | 250N/mm2 |

| Dynamic | 140N/mm2 | |

| Oscillating | 60N/mm2 | |

| PV limit | Dry | 3.6N/mm2.m/s |

| Oil | 50N/mm2.m/s | |

| Temp.limit | -195°C~+280°C | |

| Friction Coeff. | 0.03~0.20μ | |

| Speed limit | Dry | 2m/s |

| Oil | 5m/s | |

| Thermal conductivity | 2.41Kcal/M.br.c | |

| Coeff. Of linear expansion | 27×10-6per°C | |

- Q: Why are the bearings on the crankshaft of the engine sliding bearings? So high speed, sliding bearings friction is not great?? Fever will not be great? Please prawns in detail, thank you

- The reasons are as follows:The main reason is that the sliding bearing sleeve is two pieces, so it can be installed on the crankshaft. The rolling bearing can not be installed on the crankshaft.The utility model has the advantages of simple structure, low cost, easy lubrication, convenient installation, easy sealing, low noise and high precision. As long as the material pass, wear little.In addition, for a precision problem, nor is it suitable for other bearings.As for other places, both work speed, noise, work conditions, rotation accuracy, withstand shock, vibration ability, maintenance is not the same. The sliding bearing has the characteristics of high bearing capacity, good seismic resistance, low noise, long service life, etc. the rolling bearing has the characteristics of shock, vibration, noise and sealing. Rolling bearings are standard parts, easy to change. Plain bearings consume nonferrous metals.

- Q: Which one is good for sliding bearings?

- ZQFYT series radial thrust bearing, VZB series vertical thrust bearing manufacturers; is the production base of professional production of large gas turbine bearing, turbine, blower, compressor, oxygen making machine, rolling machine, ball mill, rotary kiln and so on.

- Q: On what occasions are plain bearings used?

- 6, small size occasions must be used;7 、 bearings under special working conditions.

- Q: What effect does the sliding bearing have on the top gap?

- There must be a gap between the clearances.The fit between the sliding bearing and the shaft is clearance fit. The top gap is normally pressed by lead. The top clearance is 1/1000 or 1/1000 of the axle neck, and five of the gap is 1/2 of the top clearance.

- Q: In general, what kind of sliding bearing material is used in the case of large load?

- The material selection of sliding bearing is related to load, speed, lubrication conditions, and the self-lubricating materials chosen in different working conditions are different.

- Q: Bearing is the bearing?

- No, that's the combination of the bearings and the sockets.

- Q: What is the bearing force value, how to determine, how to adjust, what is the effect?

- Bearing preload value of the end is lower level put a root diameter of 1mm length 100mm wire (A1, A2), motor or pump mechanical corresponding middle bearing upper same diameter and length of wire (B1), and then fasten the bearing shell and lid, with a screw tightening, then open remove the flat wire, so the bearing force value of s=b1- (a1+a2) /2, mm.

- Q: How many times does the clearance of the sliding bearing take the diameter of the axle?

- The range of sliding bearing clearance according to the use of precision parts to determine, for example: grinder and lathe dividing head main bearing with the accuracy of H7/g6, agricultural machinery bearings with accuracy of H11/d11.

- Q: In the design of imperfect liquid lubricated sliding bearings, what should be done to check the bearings?

- PV is the product of a certain bearing and bearing in line speed conditions and the PV value is inversely proportional to the service life of the bearing;

- Q: 250 kilowatts of motors, replacement of new bearings, after driving bearing fever, the bearings inside the grease all thrown out What's the matter? Expert answer!

- Bearing heating causes:(1) the temperature of motor bearings is high. It is suspected that the gap between the couplings of the equipment is not adjusted properly, and a little vibration causes the excessive temperature rise of the bearings.(2) the rationality of the motor design, manufacturing quality, installation quality, etc..(3) bearing quality problems caused by heating, bearing gap.Bearing (Bearing) is an important component of modern mechanical equipment. Its main function is to support the mechanical rotating body, reduce its friction coefficient (friction, coefficient) during movement, and guarantee its rotary accuracy (accuracy).According to the friction property of the moving element, the bearings can be divided into two kinds: rolling bearing and sliding bearing. Among them, the rolling bearing has been standardized and serialized, but compared with the sliding bearing, its radial dimensions, vibration and noise are relatively large, and the price is higher.Generally, the rolling bearings are composed of four parts, namely, outer ring, inner ring, roller and cage. Strictly speaking, the rolling bearings are composed of six big parts, namely, outer ring, inner ring, rolling body, cage, seal and lubricating oil. Mainly with the outer ring, inner ring, rolling body can be defined as rolling bearings. According to the shape of the rolling element, the rolling bearings are divided into two major categories: ball bearings and roller bearings.

Send your message to us

slide bearing absorber bushing plain bearing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords