scaffolding forged swivel coupler

- Loading Port:

- Nanjing

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 30000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

German style drop forged swivel coupler

1.size:48.3mm

2.weight:1.3kg

3.Material: Q235/225/345

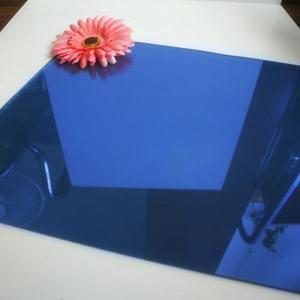

4.surface :self-color / zinc plate / electro galvanized / HDG or painted

5.Standard: EN74 ,BS1139

6.Anti-rust ,skidproof ,high breaking strength

7.Durable finish, reliability, low maintenance, corrosion resistance, robust construction and high tensile strength

8. OEM serice is available

SPECIFICATIONS:

1 MATERIAL:Q235

2 SWIVEL AND DOULE RIGHT ANGLE COUPLER

3 DROP FORGED AND PRESSED

4 BS1139 AND EN74 STANDARD

5 SIZE:48.3*48.3MM

6 PRESSED AND DROP FORED SWIVEL AND FIXED COUPLER/PUTLOG COUPLER/SLEEVE COUPLER/INNER CONNECTOR/BEAM COUPLER ETC.

Pressed swivel coupler 1.02kg galvanized/ hot dipped galvanized

- Q:I had my scaffold pierced sometime last year but it went all dodged + got infected so i had to take it out. I want to get it redone this summer holiday in the same place. So will it hurt anymore than it would usually if its going through scar tissue?Answers much appreciated!xx

- The tragus isn't painful in any respect. It has no nerve endings so which you sense much less discomfort with that than you may with the different cartilage piercing. i could think of that it hurts much less to heal than a scaffold simply by fact this is out of ways. What I propose is, a scaffold piercing gets interior the way of having dressed, brushing hair, drowsing and so on. yet a tragus isn't that undesirable simply by fact this is closer on your head. with a bit of luck that made experience haha.

- Q:Are steel tube couplers suitable for scaffolding applications in extreme weather conditions?

- Yes, steel tube couplers are suitable for scaffolding applications in extreme weather conditions. Steel is known for its strength and durability, making it highly reliable even in harsh weather conditions such as heavy rain, strong winds, or extreme temperatures. Steel tube couplers provide a secure and stable connection between scaffold tubes, ensuring the safety and stability of the scaffolding structure even in challenging weather conditions.

- Q:A 115 kg scaffold is 6 m long. It is hanging with two wires, one from each end. A 540 kg box sits 1.8 m from the left end. What is the tension in the right hand side wire?(g = 9.8 m/s2)

- this is a torque question with two unknowns i.e. the two tension forces in the wires. to find the tension in the right one, let the pivot point be at the connection of the wire (the left one) and the scaffold. Then the following calculation: let T=tension in right wire r=the lever arm length the angle is 90 so no need to worry about the angle as sin90=1 sum of the anticlockwise moments=sum of the clockwise moments 6T=540x9.8x1.8+3x115x9.8 T=2151.1N (upwards) draw a diagram it helps you to see the question more clearly

- Q:so i got my scaffolding pierced 10 days ago, yesterday i went to the piercer and they said i was able to change from two seperate smaller bars to the long barbell. which is what i did last night, but now it is really painful but only on the bottom piercing, the top one is only painful to touch whereas the bottom one has a throbbing pain and is really swollen and red. ive been cleaning it but is this normal? im not taking it out or changing it as that will irritate it more and i don't want that so. any ideas? thanks

- You're not supposed to change jewelry until the piercing has healed. It can irritate and infect the piercing. I'd say it's just irritated right now. But I'd keep a close eye on it. If there's any puss, go to a doctor. Not back to your piercer. Your piercer should know that you can't change jewelry until it's healed, and they might've really screwed up your piercing. So if there's puss, definitely see a doctor. But right now just take some anti-inflammatories and do sea salt soaks and antibacterial soap washes. You can also buy tea tree oil and add a few drops to the sea salt soak. Tea tree oil is great with helping the healing process, and it can be found at any drug store or walmart! Just clean it, and keep a close eye on it. Industrials need to be babyed during the healing process since they're one of the most difficult healers. Good luck!

- Q:Are steel tube couplers compatible with different scaffolding materials, such as wood or bamboo?

- Steel tube couplers are primarily intended for use with steel scaffolding materials, as they are engineered to securely connect steel tubes and provide stability and strength to the scaffolding structure. However, it is important to note that these couplers may not be fully compatible with alternative scaffolding materials like wood or bamboo. This is because wood and bamboo have distinct properties and dimensions compared to steel, and thus require specific types of connectors or fasteners to ensure proper attachment and structural integrity. Using steel tube couplers with wood or bamboo scaffolding materials may not offer the necessary strength and stability required for a safe and reliable scaffolding system. Therefore, it is crucial to select connectors or fasteners that are specifically designed for wood or bamboo scaffolding, in order to guarantee a secure and sturdy structure. To summarize, although steel tube couplers are designed to be compatible with steel scaffolding materials, they may not be suitable for use with different materials such as wood or bamboo. It is essential to consult with experts or refer to manufacturer guidelines to ensure proper and safe compatibility between the scaffolding materials and connectors.

- Q:How do steel tube couplers affect the stability and integrity of a scaffolding structure?

- The stability and integrity of a scaffolding structure greatly depend on steel tube couplers. These couplers play a crucial role in connecting and securing the steel tubes, creating a strong and stable framework for the scaffold. To begin with, steel tube couplers establish a dependable and robust connection between the steel tubes. This connection ensures that all the components of the scaffolding remain firmly attached, preventing any movement or displacement. This stability is vital for the safety of workers who rely on the scaffold for support while working at heights. Additionally, steel tube couplers distribute the load evenly across the structure. When weight is applied to the scaffold, such as workers, tools, or materials, the couplers help to evenly distribute this load throughout the framework. This distribution minimizes stress concentrations on any specific section, thus enhancing the overall stability and integrity of the scaffolding structure. Consequently, the risk of collapse or failure is reduced. Moreover, steel tube couplers enhance the rigidity of the scaffolding. By connecting the steel tubes at various angles and joints, the couplers resist lateral or horizontal forces that may act on the scaffold, such as wind or vibrations. This increased rigidity ensures that the scaffolding remains stable and secure, even when subjected to external forces or environmental conditions, thus providing a safe working platform for workers. It is important to note that the quality and strength of the steel tube couplers are crucial for the stability and integrity of the scaffolding structure. It is essential to use couplers made from high-quality materials and meeting industry standards. Regular inspections and maintenance of the couplers are also necessary to identify any signs of wear, damage, or corrosion that may compromise the stability of the scaffold. In conclusion, steel tube couplers are vital components that significantly impact the stability and integrity of a scaffolding structure. They establish a secure connection between steel tubes, distribute the load evenly, and enhance the rigidity of the scaffold. Ensuring the quality and proper maintenance of these couplers is essential for maintaining a safe and reliable scaffolding system.

- Q:How do steel tube couplers ensure a secure connection without damaging the tubes?

- The secure connection between tubes is guaranteed by steel tube couplers, which combine design features and material properties to prevent any damage. To begin, steel tube couplers are meticulously engineered to fit the tubes perfectly, ensuring a tight and secure fit. This precise design eliminates any play or movement when the tubes are inserted into the couplers. Consequently, the risk of slippage or misalignment is minimized, resulting in a secure connection. Furthermore, steel tube couplers often incorporate internal gripping mechanisms or teeth that enhance the connection's strength and stability. These features create an interlocking effect between the coupler and the tube, evenly distributing the load across the tube surface. By doing so, any localized stress concentration that could potentially damage the tubes is minimized. In addition, steel possesses exceptional strength and durability properties, making it an ideal material for tube couplers. Its high tensile strength and resistance to deformation allow the couplers to withstand significant loads without yielding or deforming. As a result, the tubes are securely held in place without suffering any damage, even under extreme conditions or heavy loads. Moreover, steel tube couplers often incorporate protective measures, such as coatings or galvanization, to prevent corrosion. These protective layers safeguard the coupler from rust and corrosion, which could weaken the connection and potentially damage the tubes over time. By preserving the integrity of the couplers, the risk of tube damage is significantly reduced. In conclusion, the combination of precise design, internal gripping features, the strength of steel, and protective coatings ensures a secure connection between tubes without causing any damage. This comprehensive approach creates a dependable and robust connection that can withstand loads and forces without compromising the tubes' integrity.

- Q:Can steel tube couplers be used in scaffolding projects with fragile surfaces?

- When working on scaffolding projects with fragile surfaces, it is important to take extra precautions to ensure safety. Steel tube couplers, which provide a secure connection between scaffold tubes, are essential for the stability of the structure. However, fragile surfaces are more susceptible to damage, so specific measures must be taken. One option is to use protective padding or cushions between the steel tube couplers and the fragile surface. This helps distribute weight evenly and reduces the risk of damage. Additionally, using larger base plates or spreader plates under the scaffold feet can further distribute the load and minimize impact. Careful planning and design of the scaffolding system are also crucial. The weight should be evenly distributed, and concentrated loads on the fragile surface should be avoided. Adequate bracing and support should be provided to prevent movement or shifting that could damage the surface. Regular inspections and monitoring of the scaffolding system are important to identify any potential issues or signs of damage. Promptly addressing any stress, movement, or damage is necessary to prevent further harm. In conclusion, while steel tube couplers can be used on scaffolding projects with fragile surfaces, it is essential to take additional precautions such as using protective padding, larger base plates, and careful planning. This will minimize the risk of damage and ensure the safety of the fragile surface.

- Q:How are steel tube couplers attached to scaffolding tubes?

- Scaffolding tubes are typically connected to steel tube couplers using a straightforward and efficient technique. The procedure involves sliding the coupler onto the tube's end and subsequently tightening the bolts or screws on the coupler to firmly secure it. The coupler is engineered with a split sleeve that tightly clings to the tube, guaranteeing a secure linkage. This approach facilitates effortless and rapid coupler installation and removal, eliminating the requirement for any specialized equipment. The attachment of steel tube couplers to scaffolding tubes holds immense significance as it establishes the scaffolding system's structural framework, delivering stability and support to workers and materials present at the site.

- Q:Can steel tube couplers be used in scaffolding projects with multiple work platforms?

- Steel tube couplers have the capability to be utilized in scaffolding projects that involve multiple work platforms. It is a common practice to employ steel tube couplers in scaffolding as a means to connect and secure the tubes together, thereby ensuring stability and support. These couplers are specifically designed to endure heavy loads and establish a secure connection between the scaffolding tubes. In projects that encompass multiple work platforms, steel tube couplers serve the purpose of linking the various levels of scaffolding, thereby enabling workers to safely access and carry out tasks on each platform. Moreover, steel tube couplers possess versatility and can be easily adjusted and repositioned as required, thereby rendering them well-suited for scaffolding projects involving multiple work platforms.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

scaffolding forged swivel coupler

- Loading Port:

- Nanjing

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 30000 pc/month

Offcanvas right

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches