Frame-Connected Scaffolding with Ideal Materials for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

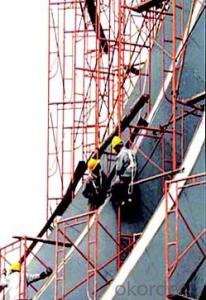

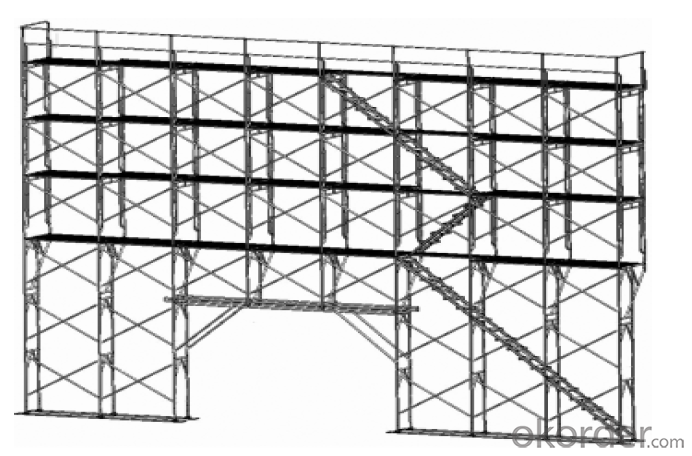

1. Structure of Frame-Connected Scaffolding

Presented like a shape of door , Frame-connected Scaffolding includes main frame, horizontal frame, cross brace, stage board and adjustable base. In order to display frame with couple system enough, good performance of stability ,firm structure of the whole, easy and fast to assemble and dismantle without any tools, safe working at height especially, and it is ideal material for construction engineering.

It can be widely used for industrial and civil construction and maintenance, such as workshop, large gymnasium, conference& exhibition center conversation, billboard, market, dock, tunnel, subways, etc. used for mobile working platform installation of electrical & mechanical engineering, ship repair and other decoration engineering, for building temporary stand ,with simple roof frame, frame-connected Scaffolding can from temporary dormitory, depot and work shed.

2. Main Features of Frame-Connected Scaffolding

.Reasonable structure, simple assembly, quick operation, safety& reliability.

.Easy to transport and knock down, high efficiently, save massive manpower and resource

.Easy to carry and operate with the weight about 20kg/p

.Assembly& disassembly with hands only to improve the efficiency highly, frame-connected scaffolding of assembly &disassembly saves half of the time than fasten steel-pipe scaffolding, and two third of the time than bamboo scaffolding.

.Widely usage, reasonable and practical, low aggregate cost.

3. Frame-Connected Scaffolding Images

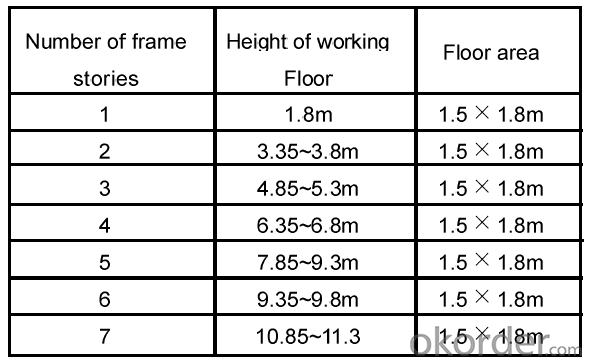

4. Frame-Connected Scaffolding Specification

.Maximum breaking load: 22.2t

.Safe working loads on jack components(safety factor:3.5)

5. FAQ of Frame-Connected Scaffolding

1) What can we do for you?

We can ensure the quality of the vinyl banner and avoid extra expenses for customers.

.We can provide you the professional design team.

.We can provide fashionable and newest styles for you.

.We can design the artwork for you.

. Please feel free to customize.

2) What promises can be done by us?

. If interested in Frame-Connected Scaffolding, please feel free to write us for any QUOTE.

. If printing required, please advise asap because the whole set need much more time to complete.

. Please DO check goods when courier knocks your door and contact us asap if any issue.

3) What about of our after-sale service?

. Response will be carried out in 24hours after receiving any complain or request.

. Frame-Connected Scaffolding cost can be refund after order is confirmed.

. If the products are not based on the requirements, there will be the relevant compensations made for you.

4) What about the package and shipping time?

.Packing: As Customer's Requirements

.Shipping: We have various shipping ways for our customers, such as express which including TNT, DHL, FEDEX, UPS, EMS, etc. ; by air/ sea, and we are VIP of these express.

.Shipping time:

Normally small orders, it just 10-15 business days to arrive your hand; When comes to the customs declaration, it may need 7 days.

Other mass qty of Frame-Connected Scaffolding, we send them out by sea or by air to sea port or air port to save some shipping freight for our customers. By ocean, it may need 45~60days, by air, it may need 25~40days.

- Q: How is a steel tube coupler used in scaffolding?

- The coupling of steel tubes is an indispensable aspect of scaffolding, ensuring the steadfast union of two tubes. This coupling, known as a steel tube coupler, guarantees the stability and safety of the scaffold structure. Comprised of two halves, each possessing threaded holes in alignment with the tubes they connect, the coupler is effectively secured by bolts. These bolts, once tightened, firmly hold the tubes in place. The coupler's design allows for effortless installation and removal, facilitating swift assembly and disassembly of the scaffold. To utilize a steel tube coupler in scaffolding, the initial step involves positioning the tubes to be joined. Subsequently, the coupler is positioned over the two tubes, aligning the threaded holes with the tube ends. Bolts are then inserted through the holes and subsequently tightened using a wrench or spanner, thus establishing a secured connection. One notable advantage of employing steel tube couplers in scaffolding is their versatility. They enable the joining of tubes of varying sizes and shapes, granting flexibility in scaffold design and construction. Moreover, these couplers facilitate the creation of diverse connections, such as right angles, swivel joints, and T-joints, simplifying the construction of scaffolding structures that meet specific project requirements. In conclusion, the steel tube coupler serves as an essential component in scaffolding, ensuring the secure and reliable joining of steel tubes. It guarantees the stability and safety of the scaffold structure while offering remarkable versatility in design and construction.

- Q: Are steel tube couplers resistant to humidity or moisture?

- Steel tube couplers are generally resistant to humidity or moisture. Steel is known for its durability and strength, and when properly coated or galvanized, it becomes even more resistant to moisture. However, prolonged exposure to high levels of humidity or direct contact with water can eventually lead to corrosion. To ensure maximum resistance to moisture, it is advisable to use steel tube couplers with appropriate protective coatings or consider using stainless steel couplers, which are highly resistant to corrosion.

- Q: What is the weight of a typical steel tube coupler?

- The size and specific design of a typical steel tube coupler can cause its weight to vary. In construction and scaffolding applications, steel tube couplers can weigh anywhere from a few ounces to several pounds. To ascertain the precise weight of a particular steel tube coupler, it is imperative to consult the manufacturer's specifications or utilize a scale for weighing.

- Q: What are the common safety certifications for steel tube couplers in scaffolding?

- Steel tube couplers in scaffolding are commonly certified for safety through the British Standard (BS) EN74, the American National Standards Institute (ANSI) A10.8, and the Occupational Safety and Health Administration (OSHA) regulations. In Europe, the widely recognized BS EN74 certification establishes the standards for steel tube couplers used in scaffolding. This certification guarantees that couplers meet specific requirements concerning their material, design, dimensions, and performance. By obtaining this certification, couplers are deemed safe and capable of withstanding the loads and stresses associated with scaffolding operations. In the United States, the ANSI A10.8 standard provides guidelines for the design, testing, and utilization of couplers in scaffolding. This certification ensures that couplers fulfill the safety requirements outlined by ANSI, which align with OSHA regulations. ANSI A10.8 outlines the minimum criteria for coupler performance, encompassing strength, durability, and resistance to corrosion. Furthermore, OSHA regulations play a vital role in ensuring the safety of steel tube couplers in scaffolding. Employers are obligated to create a safe working environment, including the use of appropriately certified scaffolding components. Compliance with OSHA regulations, particularly 29 CFR Part 1926 Subpart L, which focuses on scaffolding safety, is mandatory for employers. For scaffolding companies and workers, it is crucial to verify that the steel tube couplers they employ possess the necessary certifications to guarantee safety. By adhering to these prevalent safety certifications, companies can ensure that their scaffolding structures are dependable and capable of supporting the weight and forces exerted during construction or maintenance activities.

- Q: What are the load-bearing capacities of steel tube couplers?

- The load-bearing capacities of steel tube couplers vary depending on various factors such as the size, type, and specific design of the coupler. It is crucial to refer to the manufacturer's specifications and guidelines for accurate information on load-bearing capacities.

- Q: Can steel tube couplers be used for scaffolding projects that involve working in confined spaces?

- Scaffolding projects involving work in confined spaces can utilize steel tube couplers. These couplers are frequently employed in scaffolding systems to securely connect steel tubes, resulting in a sturdy and stable structure. Their versatility allows them to be used in various scaffolding applications, including those in confined spaces. When operating within confined spaces, it is essential to guarantee the security, stability, and appropriate design of the scaffolding system to fit within the limited area. Steel tube couplers are specifically designed to establish a dependable connection between tubes, ensuring the scaffolding structure remains stable and safe, even in tight spaces. Additionally, steel tube couplers are compact and lightweight, making them suitable for use in tight areas with limited space. Their small size enables easier maneuverability and assembly in confined spaces without compromising the integrity and strength of the scaffolding structure. Moreover, steel tube couplers are renowned for their durability and resistance to environmental factors, making them suitable for various working conditions, including confined spaces. They can endure heavy loads, vibrations, and exposure to harsh weather conditions, ensuring the scaffolding system remains safe and reliable. However, it is important to note that when working in confined spaces, additional safety measures must be considered. This may involve proper ventilation, regular inspections, and adherence to safety regulations specific to working in confined spaces. It is advisable to consult with a professional scaffolding engineer or supervisor to ensure the correct design and implementation of the scaffolding system for the confined space project at hand.

- Q: How do steel tube couplers prevent tubes from separating due to lateral forces?

- Steel tube couplers prevent tubes from separating due to lateral forces by providing a secure and reliable connection between the tubes. These couplers are designed to maintain the structural integrity of the joint, ensuring that the tubes remain firmly connected even under significant lateral forces. One way these couplers achieve this is through their strong and durable construction. Steel tube couplers are typically made from high-quality steel which offers excellent strength and resistance to external forces. These couplers are designed to withstand lateral forces, such as bending or twisting, without compromising the connection between the tubes. Furthermore, steel tube couplers often utilize mechanical or friction-based connection systems. These systems are designed to create a tight and secure fit between the tubes, preventing any movement or separation. For example, some couplers feature threaded connections that require the tubes to be tightly screwed together, creating a strong bond. Other couplers may use friction-based systems that rely on frictional forces to hold the tubes together. In addition, steel tube couplers often incorporate additional features to enhance their resistance to lateral forces. These may include internal or external reinforcement elements, such as fins or grooves, which increase the contact area between the coupler and the tubes, further improving the connection strength. It is worth noting that the specific design and mechanism of steel tube couplers can vary depending on the application and required load capacity. Different types of couplers, such as mechanical couplers or welded couplers, may be used depending on the specific needs of the project. Overall, steel tube couplers prevent tubes from separating due to lateral forces by providing a robust and stable connection between the tubes. Their strong construction, mechanical or friction-based connection systems, and additional reinforcement elements ensure that the tubes remain securely joined even under significant lateral forces.

- Q: Are there any specific training requirements for using steel tube couplers in scaffolding?

- Yes, there are specific training requirements for using steel tube couplers in scaffolding. Workers must undergo proper training on how to safely and correctly assemble, disassemble, and inspect scaffolding systems that incorporate steel tube couplers. This training helps ensure that scaffolding structures are built to industry standards and that workers can identify and address any potential hazards or issues that may arise during their use.

- Q: Can steel tube couplers be used in scaffolding projects with limited overhead clearance?

- Steel tube couplers are frequently utilized in scaffolding systems to join and secure steel tubes. They establish a robust and dependable connection, guaranteeing the stability and safety of the scaffolding structure. In projects where there is restricted overhead clearance, steel tube couplers offer numerous benefits. Firstly, they possess a compact design and do not necessitate much vertical space, rendering them suitable for such projects. Secondly, they can be effortlessly adjusted and secured in confined areas, enabling the efficient assembly and disassembly of the scaffolding structure. Furthermore, steel tube couplers exhibit exceptional durability and can withstand substantial loads, ensuring the stability and safety of the scaffolding system even under challenging circumstances. Their versatility and user-friendly nature render them a popular choice for scaffolding projects with limited overhead clearance.

- Q: Can steel tube couplers be used for scaffolding projects in seismic areas with high ground motion?

- Yes, steel tube couplers can be used for scaffolding projects in seismic areas with high ground motion. Steel tube couplers are commonly used in scaffolding systems due to their strength and stability. They provide a secure connection between tubes, ensuring the overall stability and safety of the scaffold structure. In seismic areas with high ground motion, it is crucial to use reliable and durable components to withstand the forces generated by earthquakes. Steel tube couplers are designed to handle such dynamic loads and are suitable for scaffolding projects in seismic areas with high ground motion.

Send your message to us

Frame-Connected Scaffolding with Ideal Materials for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords