Frame Connected Economical Efficiency Scaffolding

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

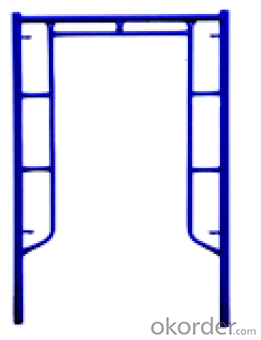

1. Structure of Frame-Connected Scaffolding

Presented like a shape of door , Frame-connected Scaffolding includes main frame, horizontal frame, cross brace, stage board and adjustable base. In order to display frame with couple system enough, good performance of stability ,firm structure of the whole, easy and fast to assemble and dismantle without any tools, safe working at height especially, and it is ideal material for construction engineering.

It can be widely used for industrial and civil construction and maintenance, such as workshop, large gymnasium, conference& exhibition center conversation, billboard, market, dock, tunnel, subways, etc. used for mobile working platform installation of electrical & mechanical engineering, ship repair and other decoration engineering, for building temporary stand ,with simple roof frame, frame-connected Scaffolding can from temporary dormitory, depot and work shed.

2. Main Features of Frame-Connected Scaffolding

.Reasonable structure, simple assembly, quick operation, safety& reliability.

.Easy to transport and knock down, high efficiently, save massive manpower and resource

.Easy to carry and operate with the weight about 20kg/p

.Assembly& disassembly with hands only to improve the efficiency highly, frame-connected scaffolding of assembly &disassembly saves half of the time than fasten steel-pipe scaffolding, and two third of the time than bamboo scaffolding.

.Widely usage, reasonable and practical, low aggregate cost.

3. Images

4. Specification

Maximum breaking load: 22.2t

Safe working loads on jack components(safety factor:3.5)

5. FAQ of Frame-Connected Scaffolding

1) What can we do for you?

We can ensure the quality of the vinyl banner and avoid extra expenses for customers.

.We can provide you the professional design team.

.We can provide fashionable and newest styles for you.

.We can design the artwork for you.

. Please feel free to customize.

2) What promises can be done by us?

. If interested in Frame-Connected Scaffolding, please feel free to write us for any QUOTE.

. If printing required, please advise asap because the whole set need much more time to complete.

. Please DO check goods when courier knocks your door and contact us asap if any issue.

3) What about of our after-sale service?

. Response will be carried out in 24hours after receiving any complain or request.

. Frame-Connected Scaffolding cost can be refund after order is confirmed.

. If the products are not based on the requirements, there will be the relevant compensations made for you.

4) What about the package and shipping time?

.Packing: As Customer's Requirements

.Shipping: We have various shipping ways for our customers, such as express which including TNT, DHL, FEDEX, UPS, EMS, etc. ; by air/ sea, and we are VIP of these express.

.Shipping time:

Normally small orders, it just 10-15 business days to arrive your hand; When comes to the customs declaration, it may need 7 days.

Other mass qty of Frame-Connected Scaffolding, we send them out by sea or by air to sea port or air port to save some shipping freight for our customers. By ocean, it may need 45~60days, by air, it may need 25~40days.

- Q: How do you properly store and transport steel tube couplers?

- To ensure the safety and prevent any damage to steel tube couplers during storage and transportation, it is important to consider the following key factors: 1. Storage: Proper storage of steel tube couplers involves keeping them in a dry and well-ventilated area to avoid moisture accumulation and corrosion. They should be kept away from direct sunlight, extreme temperatures, and chemicals that may cause harm. 2. Handling: When handling steel tube couplers, it is crucial to use appropriate lifting equipment and techniques. Dropping or dragging them should be avoided as it can result in deformation or structural damage. It is recommended to store the couplers in an upright position to prevent any distortion. 3. Packaging: Secure packaging is essential to protect the couplers during transportation. Each coupler should be individually wrapped in suitable protective material, such as bubble wrap or foam, to prevent scratches, dents, or any physical damage. Furthermore, the use of appropriate packaging materials will help prevent contact with objects that may cause corrosion or impact. 4. Transportation: During transportation, it is important to properly secure the couplers to prevent shifting or movement. They should be placed in a suitable container or vehicle with sufficient padding to avoid any impact or vibration damage. Additionally, securing them with straps or restraints will help maintain their position and prevent potential accidents. 5. Consider weight and size: It is crucial to take into account the weight and size of the steel tube couplers when planning transportation. Overloading a vehicle or container beyond its capacity can result in structural damage or accidents. Therefore, it is essential to ensure even weight distribution and stay within the load capacity of the vehicle or container. 6. Compliance with regulations: Always ensure compliance with local, national, and international transportation regulations for steel tube couplers. These regulations may include weight limits, securing requirements, and necessary documentation. By adhering to these guidelines, you can ensure the proper storage and transportation of steel tube couplers, minimizing the risk of damage or accidents and preserving their integrity for future use.

- Q: Do steel tube couplers have any limitations in terms of tube diameter or thickness?

- Yes, steel tube couplers do have limitations in terms of tube diameter and thickness. The size and specifications of the coupler will determine the range of tube sizes that can be connected using the coupler. Generally, steel tube couplers are designed to accommodate a specific range of tube diameters and thicknesses. The coupler's design and construction are based on the intended application and the loads it is expected to handle. If a tube with a diameter or thickness exceeds the specifications of the coupler, it may not fit properly or may compromise the structural integrity of the connection. It is important to consult the manufacturer's specifications and guidelines to ensure that the chosen steel tube coupler is suitable for the specific tube diameter and thickness. Additionally, professional engineering advice may be necessary to determine the appropriate coupler size and compatibility with the desired tube dimensions.

- Q: A 666 N window washer is standing on a scaffold supported by a vertical rope at each end. The scaffold weighs 396 N and is 3.72 m long. Assume the window washer stands 1.2 m from the left end. What is the tension in the rope on the right?

- This is torque problem. Let the pivot point be at the left end. The weight of the scaffold is at its center. ? * 3.72 = 1.86 meters This is the distance from the left end. The weights of the window washer and scaffold will produce clockwise torque. The tension in the on the right will produce counter clockwise torque. For the window washer, torque = 666 * 1.2 = 799.2 For the scaffold, torque = 396 * 1.86 = 736.56 Total = 799.2 + 736.56 = 1535.76 For the rope, torque = T * 3.72 T * 3.72 = 1535.76 T = 1535.76 ÷ 3.72 The tension is approximately 412.84 N

- Q: Can steel tube couplers be used in scaffolding projects with overhead structures?

- Yes, steel tube couplers can be used in scaffolding projects with overhead structures. Steel tube couplers are designed to provide a secure connection between scaffolding tubes, ensuring stability and safety. They can be used to construct scaffolding systems that can support overhead structures, such as roofs or ceilings, effectively.

- Q: How do steel tube couplers affect the overall durability and lifespan of a scaffolding system?

- Steel tube couplers play a crucial role in enhancing the overall durability and lifespan of a scaffolding system. These couplers not only provide a secure connection between the tubes but also ensure structural stability and strength. By securely joining the steel tubes, they prevent any movement or displacement, minimizing the risk of accidents and collapses. Additionally, steel tube couplers are highly resistant to corrosion and weathering, which further enhances the longevity of the scaffolding system.

- Q: Are steel tube couplers adjustable for different heights in suspended scaffolding?

- Steel tube couplers in suspended scaffolding are adjustable for different heights. These couplers are specifically designed to connect and secure the steel tubes used in constructing the scaffolding system. They are available in various types, including swivel couplers, putlog couplers, and sleeve couplers, all of which offer flexibility and the ability to adjust the height. For instance, swivel couplers are designed to connect two scaffolding tubes at any angle, allowing for height and positioning adjustments. Putlog couplers, on the other hand, are used to connect transoms or putlogs to the ledgers, extending the scaffolding horizontally at varying heights. Sleeve couplers, on the contrary, are used to join two scaffolding tubes together, providing additional length and adjustability. By utilizing these different types of steel tube couplers, suspended scaffolding can be easily adjusted to accommodate different heights according to the specific requirements of the construction or maintenance project. This adjustability guarantees the safety and stability of the scaffolding structure, while also providing workers with a comfortable working height.

- Q: Can steel tube couplers be used in scaffolding projects with restricted access or limited space?

- Yes, steel tube couplers can be used in scaffolding projects with restricted access or limited space. Steel tube couplers are versatile and can be used to connect steel tubes in various configurations, making them suitable for scaffolding projects of different sizes and shapes. Additionally, steel tube couplers are compact and do not require much space for installation. They can be easily maneuvered and fitted into tight spaces, making them ideal for scaffolding projects with restricted access or limited space. Furthermore, steel tube couplers provide strong and reliable connections, ensuring the stability and safety of the scaffolding structure. Therefore, utilizing steel tube couplers in scaffolding projects with restricted access or limited space is a practical and efficient solution.

- Q: Can steel tube couplers be used for angled or curved connections in scaffolding?

- Yes, steel tube couplers can be used for angled or curved connections in scaffolding. They are designed to provide a secure and reliable connection between scaffolding tubes, regardless of the angle or curve.

- Q: Exterior scaffolding step, pitch, span, respectively, what is the meaning

- First, the system of excellent expansion Polystyrene board thin plaster Exterior insulation system has excellent thermal insulation properties, good water resistance and compression, impact resistance, can effectively solve the wall cracks and leakage Water problem

- Q: Are steel tube couplers suitable for use in seismic or earthquake-prone areas?

- Steel tube couplers are commonly used in areas prone to seismic activity or earthquakes. These couplers are specifically engineered to establish a sturdy and dependable connection between steel tubes, guaranteeing the structural integrity of the building even when subjected to dynamic loads caused by seismic events. They offer numerous advantages in earthquake-prone regions: 1. Ductility: Steel tube couplers possess the ability to absorb and dissipate energy during an earthquake. They can endure significant deformation without failing, demonstrating a ductile behavior that aids in preventing sudden collapses or structural failures. 2. Strength: Steel tube couplers are manufactured using high-strength materials, ensuring the necessary strength to withstand seismic forces. They can handle lateral loads and displacements that occur during an earthquake without compromising the overall stability of the structure. 3. Flexibility: These couplers allow for flexibility in design and construction. They can be easily installed, adjusted, or replaced, offering an advantage in earthquake-prone areas where retrofitting or repairs may be required. 4. Compatibility: Steel tube couplers are compatible with various construction techniques and materials. They can be used in combination with reinforced concrete, steel, or timber structures, providing versatility in seismic design and construction. 5. Code Compliance: Steel tube couplers are designed and manufactured to meet or surpass international building codes and standards for seismic regions. They undergo thorough testing and quality control to ensure their performance in earthquake-prone areas. However, it is important to emphasize that the suitability of steel tube couplers in seismic or earthquake-prone areas also relies on proper engineering design, installation, and maintenance. Consulting with a qualified structural engineer is crucial to assess the specific project requirements and ensure the correct integration of the couplers into the seismic design of the structure.

Send your message to us

Frame Connected Economical Efficiency Scaffolding

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches