Frame Connected Scaffolding with High Qulity and Competitive Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

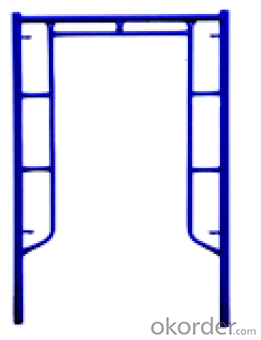

1. Structure of Frame-Connected Scaffolding

Presented like a shape of door , Frame-connected Scaffolding includes main frame, horizontal frame, cross brace, stage board and adjustable base. In order to display frame with couple system enough, good performance of stability ,firm structure of the whole, easy and fast to assemble and dismantle without any tools, safe working at height especially, and it is ideal material for construction engineering.

It can be widely used for industrial and civil construction and maintenance, such as workshop, large gymnasium, conference& exhibition center conversation, billboard, market, dock, tunnel, subways, etc. used for mobile working platform installation of electrical & mechanical engineering, ship repair and other decoration engineering, for building temporary stand ,with simple roof frame, frame-connected Scaffolding can from temporary dormitory, depot and work shed.

2. Main Features of Frame-Connected Scaffolding

.Reasonable structure, simple assembly, quick operation, safety& reliability.

.Easy to transport and knock down, high efficiently, save massive manpower and resource

.Easy to carry and operate with the weight about 20kg/p

.Assembly& disassembly with hands only to improve the efficiency highly, frame-connected scaffolding of assembly &disassembly saves half of the time than fasten steel-pipe scaffolding, and two third of the time than bamboo scaffolding.

.Widely usage, reasonable and practical, low aggregate cost.

3. Images

4. Specification

Maximum breaking load: 22.2t

Safe working loads on jack components(safety factor:3.5)

5. FAQ of Frame-Connected Scaffolding

1) What can we do for you?

We can ensure the quality of the vinyl banner and avoid extra expenses for customers.

.We can provide you the professional design team.

.We can provide fashionable and newest styles for you.

.We can design the artwork for you.

. Please feel free to customize.

2) What promises can be done by us?

. If interested in Frame-Connected Scaffolding, please feel free to write us for any QUOTE.

. If printing required, please advise asap because the whole set need much more time to complete.

. Please DO check goods when courier knocks your door and contact us asap if any issue.

3) What about of our after-sale service?

. Response will be carried out in 24hours after receiving any complain or request.

. Frame-Connected Scaffolding cost can be refund after order is confirmed.

. If the products are not based on the requirements, there will be the relevant compensations made for you.

4) What about the package and shipping time?

.Packing: As Customer's Requirements

.Shipping: We have various shipping ways for our customers, such as express which including TNT, DHL, FEDEX, UPS, EMS, etc. ; by air/ sea, and we are VIP of these express.

.Shipping time:

Normally small orders, it just 10-15 business days to arrive your hand; When comes to the customs declaration, it may need 7 days.

Other mass qty of Frame-Connected Scaffolding, we send them out by sea or by air to sea port or air port to save some shipping freight for our customers. By ocean, it may need 45~60days, by air, it may need 25~40days.

- Q: uses of scaffolding?

- scaffolding is also used as a safety barrier for demolition sites, as a catch or safety precaution for workmen and work platforms on building sites, power stations, refineries, mines, etc

- Q: What are the common warranty terms for steel tube couplers in scaffolding?

- The common warranty terms for steel tube couplers in scaffolding typically include a warranty period of one year from the date of purchase. During this period, the couplers are warranted to be free from defects in material and workmanship. However, the warranty does not cover damage caused by misuse, improper installation, or normal wear and tear. It is important to read and understand the specific warranty terms provided by the manufacturer or supplier of the steel tube couplers.

- Q: How do steel tube couplers contribute to the overall strength of scaffolding structures?

- The overall strength and stability of scaffolding structures are greatly enhanced by steel tube couplers. These couplers play a crucial role in connecting and securing steel tubes together, creating a strong and rigid framework capable of withstanding external forces and supporting heavy loads. To begin with, steel tube couplers ensure a reliable and secure connection between the tubes, keeping the scaffolding structure intact and stable during use. They are designed to tightly grip the tubes, preventing any slippage or movement that could compromise stability. Furthermore, the use of steel tube couplers allows for a versatile and flexible scaffolding system. The couplers can be easily adjusted and repositioned to create different configurations, enabling efficient and effective scaffolding in various construction or maintenance projects. This flexibility also enables scaffolding structures to adapt to different site conditions or load requirements. In addition, steel tube couplers distribute the load evenly across the connected tubes, effectively transferring the weight to the ground. This ensures that the scaffolding structure can handle heavy loads without any weak points or areas of excessive stress, maintaining stability throughout. Moreover, the use of steel tube couplers eliminates the need for welding or other permanent joining methods, making scaffolding structures easier to assemble, disassemble, and transport. This not only saves time and labor but also increases the overall efficiency and cost-effectiveness of scaffolding operations. In conclusion, steel tube couplers contribute significantly to the strength of scaffolding structures by providing secure connections, enhancing stability, distributing loads evenly, allowing for versatility, and increasing efficiency. Their use ensures the safety and reliability of scaffolding systems, making them an essential component in the construction industry.

- Q: What are the site safety regulations for building safety management?

- Polystyrene board (EPS) is a polystyrene resin as the main component, through the foam, molding made of closed-cell structure of the foam

- Q: Can steel tube couplers be used in scaffolding projects with long spans?

- Yes, steel tube couplers can be used in scaffolding projects with long spans. Steel tube couplers are commonly used in scaffolding systems to connect and secure tubes together, providing stability and strength. They are designed to withstand heavy loads and can be used in various configurations to create scaffolding structures with long spans. However, it is important to ensure that the scaffolding design and construction comply with safety regulations and guidelines to ensure the stability and integrity of the structure.

- Q: How often should steel tube couplers be inspected for damage or wear?

- Steel tube couplers should be inspected for damage or wear regularly, ideally on a quarterly basis. However, the frequency of inspections may vary depending on the specific usage and conditions the couplers are exposed to. In high-traffic or harsh environments, more frequent inspections, such as monthly or even weekly, should be considered. It is essential to prioritize safety and ensure that any potential issues with the couplers are detected early on. Regular inspections allow for timely repairs or replacements, minimizing the risk of accidents or failures. Additionally, adhering to manufacturer recommendations and industry standards can provide guidance on the recommended inspection frequency for steel tube couplers.

- Q: Can steel tube couplers be used for scaffolding projects with complex load transfer mechanisms?

- Yes, steel tube couplers can be used for scaffolding projects with complex load transfer mechanisms. Steel tube couplers are widely used in the construction industry for connecting and joining scaffolding tubes. They provide a secure and reliable connection, ensuring the stability and strength of the scaffolding structure. When it comes to complex load transfer mechanisms, steel tube couplers offer several advantages. Firstly, they can handle heavy loads and are designed to distribute the weight evenly, minimizing the risk of structural failure. Additionally, steel tube couplers provide flexibility in terms of adjusting the angles and positioning of scaffolding tubes, allowing for customization and adaptation to different load requirements. Moreover, steel tube couplers are highly durable and resistant to wear and tear, making them suitable for long-term and demanding projects. They are also easy to install and dismantle, making it convenient to modify or reconfigure the scaffolding structure as needed. However, it is important to ensure that the appropriate type and size of steel tube couplers are selected for the specific project requirements. Complex load transfer mechanisms may require specialized couplers that are specifically designed to handle the unique load distribution and transfer characteristics. Consulting with a structural engineer or a scaffolding expert can help determine the most suitable couplers for the project. Overall, steel tube couplers are a reliable and effective solution for scaffolding projects with complex load transfer mechanisms. They provide strength, stability, and versatility, making them an ideal choice for a wide range of construction applications.

- Q: Are there any specific guidelines for the safe use of steel tube couplers on uneven or sloped surfaces?

- Yes, there are specific guidelines for the safe use of steel tube couplers on uneven or sloped surfaces. When working with steel tube couplers on such surfaces, it is important to follow these guidelines to ensure safety: 1. Stability Assessment: Before using steel tube couplers on uneven or sloped surfaces, it is essential to conduct a stability assessment of the area. This assessment should evaluate the ground conditions, including the type of soil, potential for erosion, and presence of any voids or weak spots. 2. Leveling: To ensure a stable and safe setup, it is necessary to level the ground as much as possible. This can be done by filling depressions, removing loose soil, or using leveling equipment. The goal is to create a flat surface that minimizes any potential tilting or shifting of the steel tube couplers. 3. Foundation Support: If the ground is significantly uneven or sloped, additional support may be required to maintain stability. This can be achieved by using foundation supports, such as base plates or concrete footings, to create a solid and level surface for the steel tube couplers. 4. Secure Connections: Properly securing the steel tube couplers is crucial on uneven or sloped surfaces. Ensure that all connections are tightly fastened, and consider using additional measures such as locking pins or safety chains to prevent accidental disconnection. 5. Regular Inspections: Regularly inspect the steel tube couplers and the surrounding area for any signs of movement, instability, or damage. If any issues are detected, take immediate action to rectify the situation or seek professional assistance if necessary. 6. Load Capacity: Always adhere to the load capacity limits specified by the manufacturer of the steel tube couplers. Overloading the couplers can compromise their stability and pose serious safety risks, especially on uneven or sloped surfaces. 7. Communication and Training: It is important to communicate and provide appropriate training to all individuals involved in the use of steel tube couplers on uneven or sloped surfaces. This ensures that everyone understands the specific guidelines, knows how to safely install and use the couplers, and is aware of the potential risks and precautions. By following these specific guidelines, the safe use of steel tube couplers on uneven or sloped surfaces can be ensured, minimizing the risk of accidents or structural failures.

- Q: How should steel tube couplers be inspected and maintained?

- To ensure optimal performance and extend the lifespan of steel tube couplers, it is essential to regularly inspect and maintain them. The following guidelines outline the steps for inspecting and maintaining steel tube couplers: 1. Visual Assessment: Begin by visually examining the couplers for any indications of damage, corrosion, or wear. Check for cracks, deformations, or loose connections. This initial examination provides an overall understanding of the couplers' condition. 2. Lubrication: Regularly apply an appropriate lubricant compatible with the coupler material to reduce friction and prevent the accumulation of dirt and debris. This promotes smooth operation. 3. Cleanliness: Keep the couplers clean by removing dirt, rust, or other contaminants. Use a brush or cloth to cleanse the coupler surface. Avoid abrasive materials or harsh chemicals that could harm the couplers. 4. Tightening: Inspect and tighten the bolts or screws that secure the couplers according to the manufacturer's recommended torque. Loose connections can lead to misalignment and reduced efficiency. 5. Corrosion Prevention: Safeguard the couplers from rust and corrosion by applying an anti-corrosion coating or paint. This is particularly crucial if the couplers are exposed to harsh environmental conditions or moisture. 6. Periodic Inspection: Conduct regular inspections to identify any signs of wear or damage in the couplers. Depending on usage and environmental conditions, this can be done monthly or quarterly. Be attentive to changes in performance or appearance. 7. Replacement: Immediately replace severely damaged, cracked, or worn out couplers. Continuing to use faulty couplers can pose significant safety risks and compromise the structural integrity of the system. 8. Professional Inspection: In addition to regular inspections, it is advisable to periodically engage a certified engineer for a comprehensive assessment of the couplers' condition. They can provide maintenance recommendations or suggest replacements, if necessary. By adhering to these steps, steel tube couplers can be effectively inspected and maintained, ensuring their reliability and prolonged lifespan. Regular maintenance prevents costly repairs, enhances safety, and optimizes coupler performance.

- Q: Can steel tube couplers be used in scaffolding structures with uneven or sloped surfaces?

- Steel tube couplers can be used in scaffolding structures with uneven or sloped surfaces. These couplers are designed to provide a strong and secure connection between steel tubes, allowing for flexibility and adjustability in various construction environments. They can adapt to different angles and uneven surfaces, ensuring stability and safety in scaffolding structures.

Send your message to us

Frame Connected Scaffolding with High Qulity and Competitive Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches