Frame-Connected High Qulity and Convenient Scaffolding

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

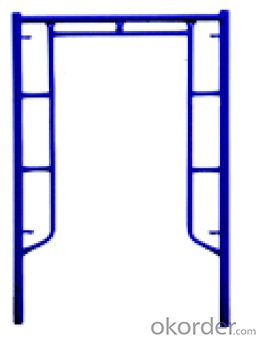

1. Structure of Frame-Connected Scaffolding

Presented like a shape of door , Frame-connected Scaffolding includes main frame, horizontal frame, cross brace, stage board and adjustable base. In order to display frame with couple system enough, good performance of stability ,firm structure of the whole, easy and fast to assemble and dismantle without any tools, safe working at height especially, and it is ideal material for construction engineering.

It can be widely used for industrial and civil construction and maintenance, such as workshop, large gymnasium, conference& exhibition center conversation, billboard, market, dock, tunnel, subways, etc. used for mobile working platform installation of electrical & mechanical engineering, ship repair and other decoration engineering, for building temporary stand ,with simple roof frame, frame-connected Scaffolding can from temporary dormitory, depot and work shed.

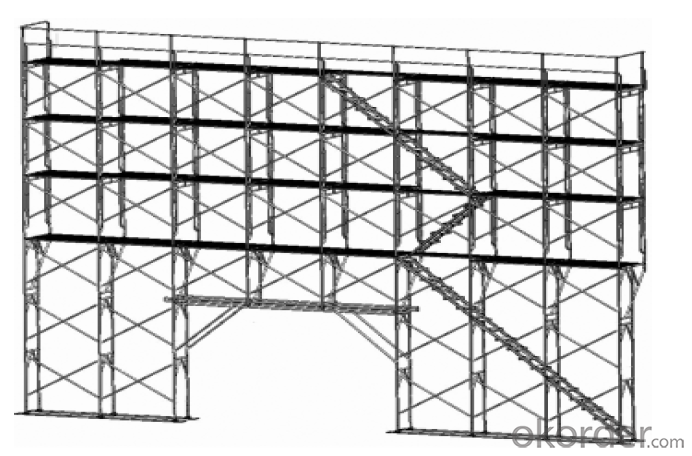

2. Main Features of Frame-Connected Scaffolding

.Reasonable structure, simple assembly, quick operation, safety& reliability.

.Easy to transport and knock down, high efficiently, save massive manpower and resource

.Easy to carry and operate with the weight about 20kg/p

.Assembly& disassembly with hands only to improve the efficiency highly, frame-connected scaffolding of assembly &disassembly saves half of the time than fasten steel-pipe scaffolding, and two third of the time than bamboo scaffolding.

.Widely usage, reasonable and practical, low aggregate cost.

3. Frame-Connected Scaffolding Images

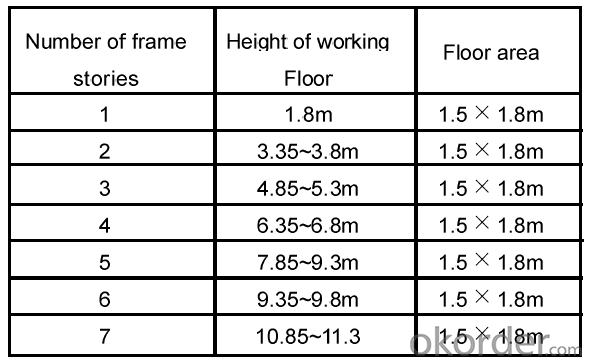

4. Frame-Connected Scaffolding Specification

.Maximum breaking load: 22.2t

.Safe working loads on jack components(safety factor:3.5)

5. FAQ of Frame-Connected Scaffolding

1) What can we do for you?

We can ensure the quality of the vinyl banner and avoid extra expenses for customers.

.We can provide you the professional design team.

.We can provide fashionable and newest styles for you.

.We can design the artwork for you.

. Please feel free to customize.

2) What promises can be done by us?

. If interested in Frame-Connected Scaffolding, please feel free to write us for any QUOTE.

. If printing required, please advise asap because the whole set need much more time to complete.

. Please DO check goods when courier knocks your door and contact us asap if any issue.

3) What about of our after-sale service?

. Response will be carried out in 24hours after receiving any complain or request.

. Frame-Connected Scaffolding cost can be refund after order is confirmed.

. If the products are not based on the requirements, there will be the relevant compensations made for you.

4) What about the package and shipping time?

.Packing: As Customer's Requirements

.Shipping: We have various shipping ways for our customers, such as express which including TNT, DHL, FEDEX, UPS, EMS, etc. ; by air/ sea, and we are VIP of these express.

.Shipping time:

Normally small orders, it just 10-15 business days to arrive your hand; When comes to the customs declaration, it may need 7 days.

Other mass qty of Frame-Connected Scaffolding, we send them out by sea or by air to sea port or air port to save some shipping freight for our customers. By ocean, it may need 45~60days, by air, it may need 25~40days.

- Q: What are the different types of steel tube couplers used in scaffolding?

- There are several different types of steel tube couplers used in scaffolding, each designed to serve a specific purpose. Some of the most common types include: 1. Double Coupler: This is the most commonly used coupler in scaffolding. It is used to connect two steel tubes at right angles to each other, creating a secure joint. Double couplers are often used in the construction of scaffolding structures. 2. Swivel Coupler: This type of coupler allows for a 360-degree rotation, making it ideal for connecting steel tubes at different angles. Swivel couplers are commonly used when scaffolding structures need to be erected on uneven ground or when the angles of the tubes need to be adjusted. 3. Sleeve Coupler: Sleeve couplers are used to connect two steel tubes end-to-end, creating longer lengths of scaffold tubes. They are commonly used when additional length is required for scaffolding structures or when scaffolding needs to be extended. 4. Putlog Coupler: Putlog couplers are specifically designed to connect putlogs or transoms to the ledgers of scaffolding structures. They are used to create a platform for workers to stand on while working on the scaffold. 5. Beam Clamp: Beam clamps are used to attach scaffolding tubes to steel beams or other structural supports. They are commonly used when scaffolding needs to be attached to existing structures, such as in industrial settings or during renovation projects. 6. Gravlock Girder Coupler: Gravlock girder couplers are designed to securely connect scaffolding tubes to steel girders or I-beams. They are commonly used in heavy-duty applications, such as in large-scale construction projects or when scaffolding needs to support heavy loads. These are just a few examples of the different types of steel tube couplers used in scaffolding. The type of coupler used will depend on the specific requirements of the scaffolding structure and the tasks being performed. It is important to choose the appropriate coupler for each application to ensure the safety and stability of the scaffold.

- Q: Can steel tube couplers be used in both temporary and permanent scaffolding structures?

- Yes, steel tube couplers can be used in both temporary and permanent scaffolding structures. They provide a secure and reliable connection between tubes, ensuring the stability and strength of the scaffolding system.

- Q: How do steel tube couplers attach to scaffolding tubes?

- Scaffolding tubes are connected using steel tube couplers, which are slid onto the end of the tube and secured in place with a tightening mechanism. The coupler consists of a sleeve and a wedge. The sleeve is a hollow cylindrical metal component that fits tightly over the tube, while the wedge is a wedge-shaped piece inserted into the sleeve. To attach the coupler, first, place the sleeve onto the tube, ensuring proper positioning and alignment. Then, insert the wedge into the sleeve with the angled side facing towards the tube. Push the wedge into the sleeve, creating a strong grip on the tube and effectively locking the coupler. Once attached, the coupler provides a secure connection between two scaffolding tubes, allowing them to be joined to form the desired structure. The tight grip ensures stability and strength, enabling the scaffolding to safely support the weight of workers and materials. It's crucial to note that trained and experienced scaffolders should handle the installation of steel tube couplers. They should have a thorough understanding of correct procedures and safety regulations. Proper installation and regular inspections are essential to maintain the integrity of the scaffolding structure and prevent accidents or failures.

- Q: a house. How far can the painter walk to the right hand side of the board before it tips? The mass of the painter is 80kg and the mass of the board is 30kg.

- Cannot be answered: insufficient data supplied. We need to know where the scaffold poles are in relation to the board.

- Q: Are steel tube couplers adjustable for different angles?

- No, steel tube couplers are not adjustable for different angles. They are designed to connect steel tubes in a straight line and cannot be adjusted to accommodate angles.

- Q: Can steel tube couplers be used in scaffolding projects with limited ground anchoring options?

- In scaffolding projects where there are limited options for anchoring to the ground, steel tube couplers can be utilized. These couplers are specifically designed to securely join scaffold tubes together, resulting in a stable and robust structure. When circumstances prevent the use of traditional ground anchoring methods, steel tube couplers provide a dependable alternative for establishing a safe scaffolding system. Manufactured from high-quality steel, these couplers are built to withstand heavy loads and ensure longevity. By creating a secure connection between scaffold tubes, they prove suitable for scaffolding projects where ground anchoring options may be scarce or impractical. Moreover, steel tube couplers offer versatility in scaffolding design and assembly. They allow for the creation of various configurations and can adapt to diverse project requirements. Consequently, scaffolding can be constructed in areas where traditional ground anchoring methods, such as base plates or anchors, may not be viable. Nevertheless, it is imperative to emphasize that employing steel tube couplers in scaffolding projects with limited ground anchoring options must be carried out in adherence to pertinent safety regulations and guidelines. Thorough planning, design, and installation are essential to guarantee the stability and safety of the scaffold structure. To summarize, steel tube couplers are a highly effective solution for scaffolding projects with limited ground anchoring options. Their durability, strength, and adaptability make them a reliable choice for establishing stable scaffolding structures in various scenarios.

- Q: How do steel tube couplers contribute to the overall versatility of a scaffolding structure?

- Steel tube couplers play a crucial role in enhancing the overall versatility of a scaffolding structure. These couplers are used to connect different steel tubes together, creating a strong and stable framework that can withstand heavy loads and provide a safe working environment. One of the primary ways in which steel tube couplers contribute to versatility is through their ability to create various configurations and shapes. Couplers allow scaffolding tubes to be connected at different angles, enabling the construction of scaffolding structures in complex and challenging environments. This adaptability allows workers to reach different heights, work around obstacles, and access hard-to-reach areas, making scaffolding structures incredibly versatile. Furthermore, steel tube couplers are easily adjustable and reusable. Unlike traditional fixed scaffolding systems, couplers can be easily detached and repositioned, allowing for quick and efficient adjustments on the job site. This flexibility is particularly valuable in situations where the scaffolding structure needs to be modified or extended during the construction process. Additionally, steel tube couplers provide a high degree of stability and strength, ensuring the safety of workers and the integrity of the scaffolding structure. The tight connection created by these couplers eliminates any wobbling or movement in the scaffolding, making it a reliable platform for workers to carry out their tasks. This stability is especially important when working at great heights or in challenging weather conditions. Moreover, steel tube couplers are compatible with a wide range of scaffolding accessories and components. This compatibility allows for the integration of additional features such as guardrails, walkways, and stairs, further enhancing the versatility and functionality of the scaffolding structure. These accessories can be easily attached or detached using the couplers, providing flexibility to adapt the scaffolding system to specific project requirements. In conclusion, steel tube couplers contribute significantly to the overall versatility of a scaffolding structure. Their ability to create various configurations, easy adjustability, stability, and compatibility with other scaffolding components make them an essential element in constructing safe, efficient, and adaptable scaffolding systems.

- Q: Can steel tube couplers be used in scaffolding structures with specialized requirements, such as protection against electromagnetic interference?

- Steel tube couplers are not suitable for scaffolding structures that require specialized protection against electromagnetic interference. This is because steel acts as a conductor of electricity and can readily transmit electromagnetic waves. Consequently, it cannot offer any defense against electromagnetic interference. In such instances, it is advisable to explore alternative materials that are non-conductive to electricity, such as fiberglass or plastic, for the couplers. This will guarantee the desired protection against electromagnetic interference.

- Q: Are steel tube couplers adjustable for different widths in scaffolding?

- Yes, steel tube couplers are adjustable for different widths in scaffolding. They are designed to accommodate various sizes of steel tubes and can be tightened or loosened to fit the desired width, providing flexibility and adaptability in scaffolding construction.

- Q: What are the common installation procedures for steel tube couplers?

- The common installation procedures for steel tube couplers typically involve the following steps: 1. Prepare the steel tubes: Ensure that the steel tubes are clean and free from any dirt, debris, or rust. This can be done by wiping them with a clean cloth and using a wire brush if necessary. 2. Measure and mark: Measure the length of the steel tubes and mark the desired location for the coupler. This will help ensure accurate placement and alignment. 3. Apply lubricant: Apply a suitable lubricant or anti-seize compound on the internal surface of the coupler. This will help facilitate a smoother installation process and prevent the coupler from seizing or getting stuck. 4. Insert the coupler: Gently insert the coupler into one end of the steel tube, ensuring that it goes in straight and fits snugly. Use a rubber mallet or a hammer with a wooden block to tap the coupler if needed. Avoid using excessive force to prevent damage. 5. Tighten the coupler: Once the coupler is fully inserted, use a wrench or a suitable tool to tighten the coupler. Follow the manufacturer's instructions or recommended torque specifications to ensure proper tightening. 6. Repeat the process: Repeat the above steps for the other end of the steel tube if necessary, depending on the specific application or project requirements. 7. Inspect and test: After installation, visually inspect the coupler and the connection to ensure proper alignment and a secure fit. If applicable, perform any necessary pressure or load testing to ensure the integrity and strength of the joint. It is important to note that the specific installation procedures may vary depending on the type of steel tube couplers being used and the specific project requirements. Therefore, it is always recommended to refer to the manufacturer's instructions or consult with a professional for specific guidance.

Send your message to us

Frame-Connected High Qulity and Convenient Scaffolding

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches