Frame Connected Scaffolding of Easy and Fast Operation

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

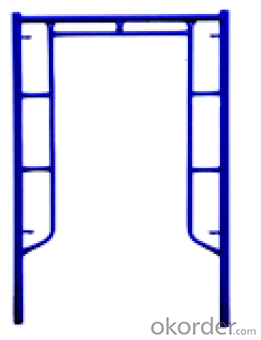

1. Structure of Frame-Connected Scaffolding

Presented like a shape of door , Frame-connected Scaffolding includes main frame, horizontal frame, cross brace, stage board and adjustable base. In order to display frame with couple system enough, good performance of stability ,firm structure of the whole, easy and fast to assemble and dismantle without any tools, safe working at height especially, and it is ideal material for construction engineering.

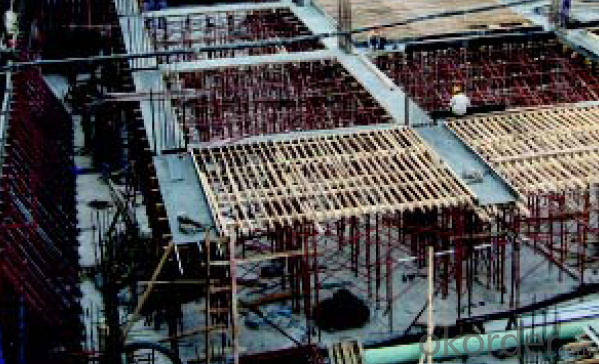

It can be widely used for industrial and civil construction and maintenance, such as workshop, large gymnasium, conference& exhibition center conversation, billboard, market, dock, tunnel, subways, etc. used for mobile working platform installation of electrical & mechanical engineering, ship repair and other decoration engineering, for building temporary stand ,with simple roof frame, frame-connected Scaffolding can from temporary dormitory, depot and work shed.

2. Main Features of Frame-Connected Scaffolding

.Reasonable structure, simple assembly, quick operation, safety& reliability.

.Easy to transport and knock down, high efficiently, save massive manpower and resource

.Easy to carry and operate with the weight about 20kg/p

.Assembly& disassembly with hands only to improve the efficiency highly, frame-connected scaffolding of assembly &disassembly saves half of the time than fasten steel-pipe scaffolding, and two third of the time than bamboo scaffolding.

.Widely usage, reasonable and practical, low aggregate cost.

3. Images

4. Specification

Maximum breaking load: 22.2t

Safe working loads on jack components(safety factor:3.5)

5. FAQ of Frame-Connected Scaffolding

1) What can we do for you?

We can ensure the quality of the vinyl banner and avoid extra expenses for customers.

.We can provide you the professional design team.

.We can provide fashionable and newest styles for you.

.We can design the artwork for you.

. Please feel free to customize.

2) What promises can be done by us?

. If interested in Frame-Connected Scaffolding, please feel free to write us for any QUOTE.

. If printing required, please advise asap because the whole set need much more time to complete.

. Please DO check goods when courier knocks your door and contact us asap if any issue.

3) What about of our after-sale service?

. Response will be carried out in 24hours after receiving any complain or request.

. Frame-Connected Scaffolding cost can be refund after order is confirmed.

. If the products are not based on the requirements, there will be the relevant compensations made for you.

4) What about the package and shipping time?

.Packing: As Customer's Requirements

.Shipping: We have various shipping ways for our customers, such as express which including TNT, DHL, FEDEX, UPS, EMS, etc. ; by air/ sea, and we are VIP of these express.

.Shipping time:

Normally small orders, it just 10-15 business days to arrive your hand; When comes to the customs declaration, it may need 7 days.

Other mass qty of Frame-Connected Scaffolding, we send them out by sea or by air to sea port or air port to save some shipping freight for our customers. By ocean, it may need 45~60days, by air, it may need 25~40days.

- Q: Are steel tube couplers compatible with different scaffold bracing systems?

- Steel tube couplers have a general compatibility with diverse scaffold bracing systems. They possess versatility, allowing them to connect various scaffold system components, including different bracing systems. Whether it be diagonal, horizontal, or any other type of bracing system, steel tube couplers ensure secure connections between tubes, resulting in a stable and safe scaffold structure. The adaptability and compatibility of steel tube couplers with different scaffold bracing systems guarantee flexibility and ease of use in construction projects.

- Q: Are steel tube couplers adjustable for different heights in scaffolding with restricted access?

- No, steel tube couplers are not adjustable for different heights in scaffolding with restricted access.

- Q: What are the common installation procedures for steel tube couplers?

- The common installation procedures for steel tube couplers typically involve the following steps: 1. Prepare the steel tubes: Ensure that the steel tubes are clean and free from any dirt, debris, or rust. This can be done by wiping them with a clean cloth and using a wire brush if necessary. 2. Measure and mark: Measure the length of the steel tubes and mark the desired location for the coupler. This will help ensure accurate placement and alignment. 3. Apply lubricant: Apply a suitable lubricant or anti-seize compound on the internal surface of the coupler. This will help facilitate a smoother installation process and prevent the coupler from seizing or getting stuck. 4. Insert the coupler: Gently insert the coupler into one end of the steel tube, ensuring that it goes in straight and fits snugly. Use a rubber mallet or a hammer with a wooden block to tap the coupler if needed. Avoid using excessive force to prevent damage. 5. Tighten the coupler: Once the coupler is fully inserted, use a wrench or a suitable tool to tighten the coupler. Follow the manufacturer's instructions or recommended torque specifications to ensure proper tightening. 6. Repeat the process: Repeat the above steps for the other end of the steel tube if necessary, depending on the specific application or project requirements. 7. Inspect and test: After installation, visually inspect the coupler and the connection to ensure proper alignment and a secure fit. If applicable, perform any necessary pressure or load testing to ensure the integrity and strength of the joint. It is important to note that the specific installation procedures may vary depending on the type of steel tube couplers being used and the specific project requirements. Therefore, it is always recommended to refer to the manufacturer's instructions or consult with a professional for specific guidance.

- Q: Are there any limitations or restrictions on the use of steel tube couplers in scaffolding?

- The use of steel tube couplers in scaffolding is subject to limitations and restrictions imposed by regulatory bodies and industry standards to ensure safety and prevent accidents. One of the primary limitations concerns the load-bearing capacity of steel tube couplers. Each coupler has a specific weight limit, and surpassing this limit can result in structural failure and potential scaffolding collapse. Distributing and calculating the load on the couplers carefully is essential to avoid overloading them. Another limitation involves the proper installation and connection of steel tube couplers. It is crucial to follow the manufacturer's instructions and guidelines for correct installation techniques. Improperly installed couplers pose a significant risk to the stability and integrity of the scaffolding structure. Moreover, certain environments or specific applications may impose restrictions on the use of steel tube couplers. For instance, corrosive or high-temperature environments can cause deterioration or weakening of the couplers over time. Similarly, industrial or hazardous work sites may require specialized couplers capable of withstanding extreme weather conditions or chemical exposure. Additionally, regulatory bodies and industry standards often require regular inspections, maintenance, and testing of scaffolding systems, including the couplers. This ensures the timely identification and resolution of potential issues or wear and tear, thereby maintaining the safety and stability of the scaffolding structure. It is crucial to familiarize oneself with local regulations and industry standards governing the use of steel tube couplers in scaffolding. Adhering to these limitations and restrictions helps prevent accidents, injuries, and potential legal liabilities.

- Q: Are there any specific guidelines for the safe use of steel tube couplers in scaffolding near overhead power lines?

- Steel tube couplers used in scaffolding near overhead power lines have specific guidelines for safe use. To prevent accidents and ensure the well-being of workers, it is crucial to adhere to safety regulations. Consider the following guidelines: 1. Prioritize a thorough risk assessment: Conducting a comprehensive risk assessment is essential before beginning work near overhead power lines. This assessment should identify potential hazards and determine necessary precautions to minimize risk. 2. Maintain a safe distance: Ensuring a safe distance between the scaffolding and overhead power lines is vital. The specific distance may vary based on local regulations, but typically a minimum of 3 meters (10 feet) is recommended. 3. Employ insulating materials: Using insulating materials when working near power lines can provide an additional layer of protection. Insulating sleeves or caps should be utilized on steel tube couplers that come into close proximity to power lines. 4. Provide adequate training for workers: It is crucial that all workers involved in scaffolding near overhead power lines receive proper training on potential risks and safety procedures. They should be familiar with safe practices and understand the importance of adhering to guidelines. 5. Establish a safe system of work: Implementing a safe system of work is necessary, including clear instructions and procedures for working near power lines. This system should be communicated to all workers and regularly reviewed to ensure everyone understands their responsibilities. 6. Utilize warning signs and barriers: Erecting warning signs and physical barriers in the scaffolding area can effectively alert workers and the public about the presence of overhead power lines. These barriers should be easily visible and prevent unauthorized access to the work area. 7. Coordinate with power companies: Coordinating with local power companies before beginning work near overhead power lines is crucial. They can provide valuable information regarding line voltage, safety requirements, and additional precautions that must be taken. 8. Conduct regular inspections: Regular inspections of the scaffolding, steel tube couplers, and other equipment should be carried out to ensure they remain in good working condition. Any signs of damage or wear should be promptly addressed to maintain safety. By following these specific guidelines, workers can minimize the risks associated with scaffolding near overhead power lines and create a safe working environment. It is important to note that local regulations and guidelines may vary, so consulting relevant authorities or safety experts for precise information is advisable.

- Q: Can steel tube couplers be used in overhead scaffolding applications?

- Yes, steel tube couplers can be used in overhead scaffolding applications. Steel tube couplers are commonly used in scaffolding systems to connect and secure steel tubes together to create a stable and sturdy structure. These couplers are designed to provide a strong and reliable connection, making them suitable for use in overhead scaffolding applications where safety and stability are paramount. Whether it is for supporting platforms, walkways, or other components of the scaffolding, steel tube couplers can effectively and securely join the steel tubes together to create a robust overhead scaffolding system.

- Q: How do steel tube couplers prevent accidental dislodging or separation of scaffolding components?

- Steel tube couplers prevent accidental dislodging or separation of scaffolding components by securely connecting and interlocking the tubes together, providing a strong and stable structure. These couplers are designed to withstand heavy loads and external forces, ensuring that the scaffolding remains intact and safe during use.

- Q: What are the common safety features or mechanisms of steel tube couplers?

- Steel tube couplers, also known as pipe couplings or pipe connectors, are commonly used in various industries for joining two or more steel tubes together. These couplers are designed to ensure the safety and reliability of the connections, and they incorporate several safety features and mechanisms. One of the most important safety features of steel tube couplers is their ability to provide a strong and secure connection. These couplers are typically made from high-quality steel, which ensures their strength and durability. They are designed to withstand heavy loads, vibrations, and external forces without compromising the integrity of the joint. This feature ensures that the connection remains intact and prevents any potential accidents or failures. Another safety mechanism of steel tube couplers is their ability to resist corrosion. Corrosion can weaken the structural integrity of a joint and increase the risk of failure. To mitigate this risk, many steel tube couplers are coated with anti-corrosion materials, such as zinc or epoxy, to protect them from rust and corrosion. This coating helps prolong the lifespan of the couplers and ensures the safety of the connection. In addition, many steel tube couplers feature a locking mechanism to enhance the safety of the joint. This mechanism typically involves bolts, nuts, or clamps that are tightened to securely hold the tubes together. The locking mechanism ensures that the connection remains tight and stable, even under high-pressure or dynamic conditions. It prevents any unintentional disconnection or separation, reducing the risk of accidents or injuries. Furthermore, some steel tube couplers incorporate additional safety features such as gaskets or seals. These components help create a watertight or airtight connection, depending on the application. By preventing the entry of water, dust, or other contaminants, these gaskets or seals help maintain the integrity of the joint and prevent any potential damage or degradation. Overall, the common safety features and mechanisms of steel tube couplers include strong and durable construction, corrosion resistance, locking mechanisms, and gaskets or seals. These features ensure the reliability and safety of the connections, making steel tube couplers a preferred choice in various industries.

- Q: How do steel tube couplers affect the overall cost of scaffolding projects?

- Steel tube couplers can have a significant impact on the overall cost of scaffolding projects. These couplers are essential components that connect the steel tubes, forming a sturdy and reliable structure. The cost of steel tube couplers can vary depending on factors such as the type and quality of the couplers, the quantity needed, and the supplier. One aspect that affects the cost is the type of steel tube couplers used. There are various types available, including swivel couplers, sleeve couplers, putlog couplers, and beam clamps. Each type has its own specifications, applications, and cost. For example, swivel couplers are typically more expensive than sleeve couplers due to their added flexibility and adjustable features. The quality of the steel tube couplers also plays a role in the overall cost. High-quality couplers are typically more expensive but offer better durability, strength, and resistance to corrosion. Investing in superior quality couplers can lead to longer-lasting scaffolding structures, reducing the need for frequent replacements and maintenance, thus potentially lowering overall costs in the long run. The quantity of steel tube couplers needed for a particular project directly affects the cost. Large-scale projects that require a significant amount of scaffolding will naturally require a greater number of couplers, resulting in higher costs. It is essential to accurately estimate the quantity needed to avoid over-purchasing and unnecessary expenses. Lastly, the choice of supplier can impact the cost of steel tube couplers. Different suppliers may offer varying prices for identical or similar products. It is crucial to research and compare prices from multiple suppliers to ensure that the best value for money is obtained. Overall, steel tube couplers can significantly affect the cost of scaffolding projects. Factors such as the type, quality, quantity, and supplier of the couplers should be carefully considered to optimize costs while maintaining the required safety and reliability of the scaffolding structure.

- Q: Are steel tube couplers compatible with scaffolding access gates and openings?

- Indeed, scaffolding access gates and openings can be paired with steel tube couplers. These couplers are widely employed in scaffolding systems for the purpose of joining steel tubes and constructing the framework. They are specifically engineered to firmly secure the tubes, guaranteeing stability and safety. By utilizing these couplers, one can affix scaffolding access gates and openings to the primary scaffolding structure, creating a dependable and steady passage for entering and exiting. It is crucial to ensure the appropriate installation of the couplers and their compatibility with the precise dimensions and type of steel tubes employed in the scaffolding system.

Send your message to us

Frame Connected Scaffolding of Easy and Fast Operation

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords