Quick Assembly Slab Formwork System with Ring Lock Scaffolding

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

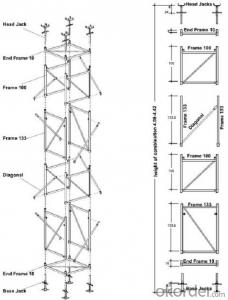

1. Brief introduction

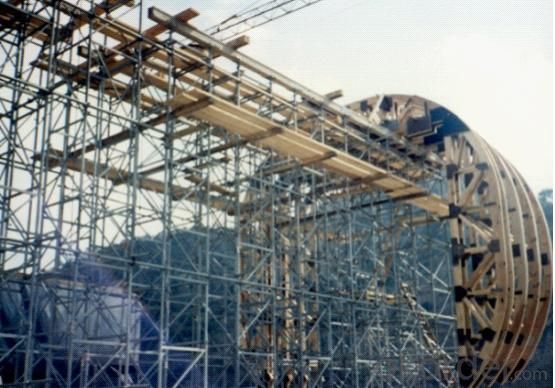

FA-TNOR system is widely used for pouring slab concrete, especially for the building which has higher story height that only using props can’t meet requirements. The system guarantees quick assembly, simple structure and easily operation, it is good choice for slab construction.

2. About the infill areas

Like RA-INST system, infill materials are necessary for small space or same special area. They are usually composed of timber beam, head-jack, scaffold support, and plywood as the below picture shown.

3. Competitive advantage

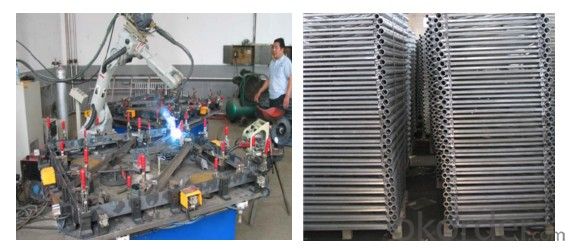

① Fast construction

The table formwork is pre-assembled; all the structural elements are connected by specific fastenings, so it is easily to move and turnover.

②Easy operation

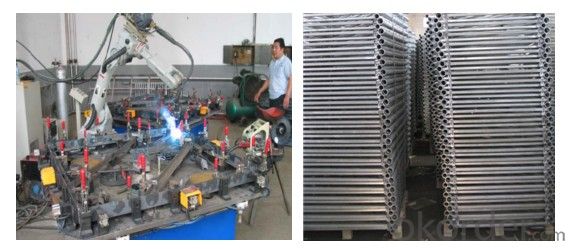

The formwork is composed of plywood, timber beam, channel beam, connectors and ring-lock scaffolding support system. It’s easy to assemble for labors with simple structure. Special skill train is no needed.

③Height of scaffolding is adjustable

Table formwork is supported with adjustable scaffoldings; the scaffoldings can be pivoted in two directions for meeting the demand of different height with adjustable head jack and adjustable foot jack.

④Mature system with specific tools for removing.

We afford trolley for FA-TNOR system, trolley is especially for shifting table formwork from the slab, it guarantees easy operation and safe removing.

4. Applications

- Q: book regarding scaffolding?

- are u refering to the scarlet letter? where the scaffold appears many times?

- Q: What are the common safety guidelines for using steel tube couplers in scaffolding?

- To ensure a safe working environment while using steel tube couplers in scaffolding, it is crucial to adhere to several standard safety guidelines. These guidelines encompass: 1. Inspection: Before employing steel tube couplers, it is imperative to thoroughly inspect them for any signs of damage or wear. If any couplers are found to be damaged, immediate replacement is necessary. 2. Proper Installation: The installation of couplers should strictly adhere to the instructions provided by the manufacturer. This entails ensuring that they are fully tightened and securely fastened to the scaffolding tubes. 3. Load Capacity: Steel tube couplers possess a specific load capacity that must not be exceeded. Hence, it is vital to be aware of the load capacity of the couplers being utilized and ensure that the scaffolding is not overloaded. 4. Alignment: Proper alignment of the couplers with the scaffolding tubes is essential to maximize strength and stability. Misalignment can weaken the structure and heighten the risk of collapse. 5. Regular Inspections: Consistent inspections should be conducted to detect any signs of damage, wear, or loosening of couplers. Regular inspections aid in identifying potential issues before they become hazardous. 6. Use of Quality Materials: Employing high-quality steel tube couplers that conform to industry standards is crucial. The utilization of substandard or counterfeit couplers can compromise the safety and stability of the scaffolding. 7. Training and Competence: Individuals involved in the assembly, disassembly, and use of scaffolding with steel tube couplers should receive proper training and possess competence in their usage. This encompasses understanding the correct techniques for erecting and dismantling the scaffolding, as well as the ability to identify and address any safety concerns. By adhering to these standard safety guidelines, the risk of accidents, collapses, or injuries associated with the utilization of steel tube couplers in scaffolding can be significantly minimized. Prioritizing safety and implementing all necessary precautions are imperative to safeguard workers and prevent accidents.

- Q: i was forced to take the bar out for school. the studs are far smaller than the bar, but if i push, i can get the bar through my earlobe piercing with no pain, so will I be able to get it through my scaffolding in the christmas holidays?I had it done for 1 week and 2 days before i had to take it out.It's 5 days til the holidays, and i've had the studs in a week.

- Did it hurt? You should be able to get the bar back thru, I know I personally make the hole in my helix bigger than the earring I usually wear in it. Its tender for a few days then its fine.

- Q: as you can see, it's kind of like that of regular scaffold bar, however, it goes out at the end and wraps around the front side of the ear, as you can see in the poorly made picturemy question is, does this sort of bar exist or am i imaging things?if it really exists, may i get the name of the type of bar it is?thank you for your help.

- Well for the piercing, you'd just get a normal industrial piercing and change to that type of bar when it has healed (fully!). As for the bar... I have never seen one like that, so you'd have to get it custom made - that could be expensive. You'd have to get in contact with a manufacturer of body jewellery and see what they can do. Good luck :) Edit: That bar, however, looks like it would be very hard to get in, so you'd definitely have to check with a piercer to make sure the piercings are healed well before you put the new jewelry in.

- Q: Can steel tube couplers be used for scaffolding applications in marine environments?

- Scaffolding applications in marine environments can utilize steel tube couplers. These couplers are widely used in construction and scaffolding projects because of their strength and durability. They are specifically designed to securely connect two steel tubes, creating a stable structure. In marine environments, where exposure to saltwater, humidity, and other corrosive elements is present, it is crucial to select materials that can withstand these conditions. Steel tube couplers are typically made from high-quality steel that is resistant to corrosion. They are often galvanized or coated with protective layers to further enhance their resistance to rust and corrosion. Furthermore, extensive testing has been conducted on steel tube couplers, proving their reliability in various environments, including marine applications. They have been successfully utilized in the construction of docks, piers, and other marine structures, where they endure constant contact with saltwater and harsh weather conditions. It is important to emphasize that regular maintenance and inspections are necessary to ensure the integrity of the scaffolding system in marine environments. This includes regularly checking for signs of corrosion, damage, or wear and tear on the steel tube couplers and promptly replacing them if needed. Overall, steel tube couplers are an appropriate choice for scaffolding applications in marine environments due to their strength, durability, and resistance to corrosion.

- Q: Can steel tube couplers be used in scaffolding applications with curved or irregular shapes?

- Steel tube couplers can be used in scaffolding applications with curved or irregular shapes, but it may require additional measures and expertise to ensure proper installation and stability. The primary purpose of steel tube couplers in scaffolding is to connect and secure the tubes together to form a stable structure. While they are commonly used in straight, vertical or horizontal configurations, they can also be utilized for scaffolding structures with curved or irregular shapes. However, when working with curved or irregular shapes, it is important to consider the specific requirements and limitations of the steel tube couplers being used. The design and specifications of the couplers should be assessed to ensure they can accommodate the varying angles and shapes of the scaffolding structure. In some cases, additional components or specialized couplers may be necessary to create the desired curved or irregular shape. These could include swivel couplers, adjustable couplers, or other specialized connectors that allow for flexibility and adjustment. Furthermore, it is crucial to consult with experienced scaffolding professionals or engineers who can provide guidance and expertise in designing and constructing scaffolding systems with curved or irregular shapes. They can analyze the specific requirements of the project and recommend the appropriate couplers and techniques to ensure the stability and safety of the scaffolding structure. Overall, while steel tube couplers can be used in scaffolding applications with curved or irregular shapes, it is essential to carefully consider the specific requirements and seek professional advice to ensure proper installation and structural integrity.

- Q: Can steel tube couplers be used for scaffolding structures that need to be assembled or disassembled quickly?

- Scaffolding structures requiring swift assembly or disassembly can indeed utilize steel tube couplers. These couplers are widely employed within the construction industry due to their adaptability, durability, and user-friendliness. Their purpose is to securely connect steel tubes, facilitating efficient and speedy assembly and disassembly of scaffolding structures. By ensuring a dependable and stable connection, they uphold safety and stability during scaffolding use. Moreover, steel tube couplers can be reused, making them a cost-effective and pragmatic option for projects necessitating frequent assembly and disassembly. All in all, when it comes to scaffolding structures demanding prompt assembly or disassembly, steel tube couplers are an outstanding choice.

- Q: Can steel tube couplers be used in scaffolding structures with specialized requirements, such as access for disabled individuals?

- Yes, steel tube couplers can be used in scaffolding structures with specialized requirements, including access for disabled individuals. The use of steel tube couplers allows for flexibility in designing scaffolding structures to meet specific accessibility requirements, such as installing ramps or wider platforms to accommodate wheelchairs. Additionally, steel tube couplers provide the necessary strength and stability to ensure the safety of the scaffolding structure for all users, including disabled individuals.

- Q: What is the typical weight of steel tube couplers used in scaffolding?

- The typical weight of steel tube couplers used in scaffolding can vary depending on the specific type and size of the coupler. However, on average, steel tube couplers used in scaffolding typically weigh between 0.5 to 2 pounds (0.23 to 0.91 kilograms). It is important to note that the weight can also be influenced by factors such as the material thickness and overall design of the coupler.

- Q: How do steel tube couplers ensure the proper alignment of scaffolding tubes?

- Steel tube couplers ensure the proper alignment of scaffolding tubes by securely connecting them together, providing a strong and stable structure. These couplers are designed to fit tightly around the tubes, ensuring a snug fit and preventing any movement or misalignment. This ensures the overall stability and safety of the scaffolding system.

Send your message to us

Quick Assembly Slab Formwork System with Ring Lock Scaffolding

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches