Frame-Connected Adjustable and Safety Scaffolding

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

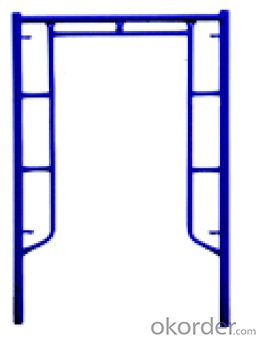

1. Structure of Frame-Connected Scaffolding

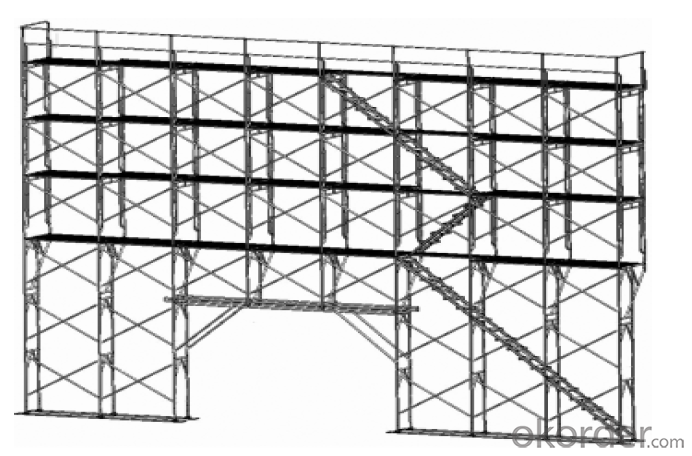

Presented like a shape of door , Frame-connected Scaffolding includes main frame, horizontal frame, cross brace, stage board and adjustable base. In order to display frame with couple system enough, good performance of stability ,firm structure of the whole, easy and fast to assemble and dismantle without any tools, safe working at height especially, and it is ideal material for construction engineering.

It can be widely used for industrial and civil construction and maintenance, such as workshop, large gymnasium, conference& exhibition center conversation, billboard, market, dock, tunnel, subways, etc. used for mobile working platform installation of electrical & mechanical engineering, ship repair and other decoration engineering, for building temporary stand ,with simple roof frame, frame-connected Scaffolding can from temporary dormitory, depot and work shed.

2. Main Features of Frame-Connected Scaffolding

.Reasonable structure, simple assembly, quick operation, safety& reliability.

.Easy to transport and knock down, high efficiently, save massive manpower and resource

.Easy to carry and operate with the weight about 20kg/p

.Assembly& disassembly with hands only to improve the efficiency highly, frame-connected scaffolding of assembly &disassembly saves half of the time than fasten steel-pipe scaffolding, and two third of the time than bamboo scaffolding.

.Widely usage, reasonable and practical, low aggregate cost.

3. Frame-Connected Scaffolding Images

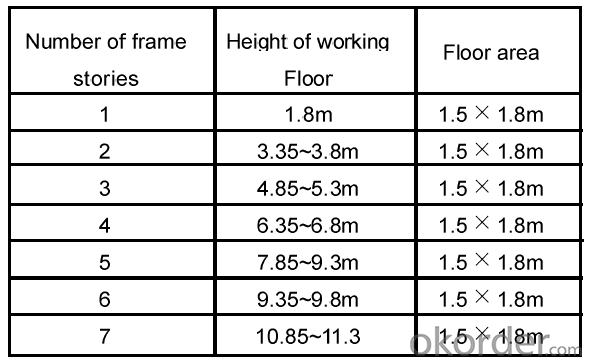

4. Frame-Connected Scaffolding Specification

.Maximum breaking load: 22.2t

.Safe working loads on jack components(safety factor:3.5)

5. FAQ of Frame-Connected Scaffolding

1) What can we do for you?

We can ensure the quality of the vinyl banner and avoid extra expenses for customers.

.We can provide you the professional design team.

.We can provide fashionable and newest styles for you.

.We can design the artwork for you.

. Please feel free to customize.

2) What promises can be done by us?

. If interested in Frame-Connected Scaffolding, please feel free to write us for any QUOTE.

. If printing required, please advise asap because the whole set need much more time to complete.

. Please DO check goods when courier knocks your door and contact us asap if any issue.

3) What about of our after-sale service?

. Response will be carried out in 24hours after receiving any complain or request.

. Frame-Connected Scaffolding cost can be refund after order is confirmed.

. If the products are not based on the requirements, there will be the relevant compensations made for you.

4) What about the package and shipping time?

.Packing: As Customer's Requirements

.Shipping: We have various shipping ways for our customers, such as express which including TNT, DHL, FEDEX, UPS, EMS, etc. ; by air/ sea, and we are VIP of these express.

.Shipping time:

Normally small orders, it just 10-15 business days to arrive your hand; When comes to the customs declaration, it may need 7 days.

Other mass qty of Frame-Connected Scaffolding, we send them out by sea or by air to sea port or air port to save some shipping freight for our customers. By ocean, it may need 45~60days, by air, it may need 25~40days.

- Q: Can steel tube couplers be used in scaffolding projects with limited working space?

- Yes, steel tube couplers can definitely be used in scaffolding projects with limited working space. Steel tube couplers are versatile and can be easily attached to steel tubes to create secure connections in scaffolding structures. They come in various sizes and types, such as swivel couplers, sleeve couplers, and putlog couplers, allowing for flexible configurations in tight spaces. These couplers provide a strong and reliable connection, ensuring the stability and safety of the scaffolding system. Additionally, steel tube couplers are compact and do not require additional space for assembly or disassembly, making them ideal for projects with limited working space.

- Q: How do steel tube couplers compare to other types of scaffolding connectors in terms of cost-effectiveness?

- Steel tube couplers are generally more cost-effective compared to other types of scaffolding connectors. This is because they are durable, reusable, and have a longer lifespan, reducing the need for frequent replacements. Additionally, steel tube couplers are versatile and can be used with various scaffold tube sizes, eliminating the need for multiple connector types. Overall, their durability and flexibility make them a cost-effective choice for scaffolding projects.

- Q: Can steel tube couplers be used to connect different sizes or types of scaffolding tubes?

- Steel tube couplers have the capability to connect scaffolding tubes of varying sizes and types. They are designed to ensure a secure and dependable connection between the tubes, regardless of their size or type. These couplers are specifically manufactured to accommodate different tube diameters, allowing for the connection of tubes with varying sizes, including joining larger diameter tubes with smaller ones or vice versa. Moreover, steel tube couplers possess versatility in connecting tubes made from diverse materials, such as steel, aluminum, or composite materials. This adaptability facilitates the effortless assembly and disassembly of scaffolding structures, making them suitable for a wide range of construction or maintenance projects.

- Q: Can steel tube couplers be used in scaffolding systems that require adjustable height or length?

- Yes, steel tube couplers can be used in scaffolding systems that require adjustable height or length. Steel tube couplers are commonly used in scaffolding systems to connect and secure steel tubes together. They provide a strong and reliable connection, allowing for the creation of stable scaffolding structures. In scaffolding systems that require adjustable height or length, steel tube couplers can be used in conjunction with adjustable components such as telescopic tubes or adjustable base plates. By using these adjustable components, the height or length of the scaffolding system can be easily adjusted to meet the specific requirements of the project. Furthermore, steel tube couplers are designed to be flexible and versatile, allowing for various configurations and angles to be achieved. This flexibility enables scaffolding systems to be easily adapted and modified as needed, making them suitable for projects that require adjustable height or length. Overall, steel tube couplers are a reliable and effective solution for scaffolding systems that require adjustable height or length. They provide a strong connection and can be used in conjunction with adjustable components to create versatile and adaptable scaffolding structures.

- Q: Can steel tube couplers be used for both straight and curved scaffolding designs?

- Steel tube couplers possess the capability to serve both straight and curved scaffolding designs. Their versatility permits the connection of steel tubes or pipes at different angles and arrangements. This results in a robust and reliable linkage, rendering them appropriate for both straight and curved scaffolding designs. Whether the structure is a vertical one or possesses a curved shape, steel tube couplers enable the creation of a stable and secure scaffolding system. The adaptability of steel tube couplers facilitates effortless adjustment and accommodation to diverse scaffolding designs, establishing them as a favored option in the construction sector.

- Q: Can steel tube couplers be used in scaffolding projects that require temporary enclosure or containment?

- Yes, steel tube couplers can be used in scaffolding projects that require temporary enclosure or containment. Steel tube couplers are commonly used in scaffolding as they provide a strong and secure connection between scaffolding tubes. They can be easily used to construct temporary enclosures or containment structures by connecting the necessary scaffolding tubes together.

- Q: What are the common applications of steel tube couplers in scaffolding?

- Steel tube couplers are widely used in scaffolding for various applications. Some of the common applications of steel tube couplers in scaffolding are as follows: 1. Joining tubes: Steel tube couplers are primarily used to connect and join different lengths of steel tubes. They provide a strong and secure connection, ensuring the stability and safety of the scaffolding structure. 2. Creating scaffolding frames: Couplers are used to create scaffolding frames by connecting horizontal and vertical tubes. These frames provide a sturdy platform for workers to access elevated areas safely. 3. Forming bracing and diagonal supports: Steel tube couplers are also used to form bracing and diagonal supports in scaffolding structures. These supports help in distributing the load evenly across the scaffolding system and enhance its stability. 4. Securing scaffold boards: Couplers are used to secure scaffold boards in place, creating a stable working platform for workers. They prevent the boards from moving or slipping, reducing the risk of accidents or injuries. 5. Attaching accessories: Steel tube couplers can be used to attach various accessories to the scaffolding system, such as guardrails, toe boards, and safety nets. These accessories enhance the safety and functionality of the scaffolding structure. 6. Modular assembly: Steel tube couplers allow for modular assembly of scaffolding systems. This means that scaffolding structures can be easily assembled, disassembled, and reconfigured as per the specific requirements of a project. Couplers enable quick and efficient construction, saving time and labor costs. 7. Load distribution: Couplers play a crucial role in distributing the load across the scaffolding structure. They ensure that the weight is evenly distributed, preventing overloading and minimizing the risk of structural failure. 8. Versatility: Steel tube couplers are compatible with various sizes and types of steel tubes, offering versatility in scaffolding applications. They can be used with both standard and non-standard tube sizes, allowing for flexibility in scaffolding design and construction. In summary, steel tube couplers are essential components in scaffolding systems, used for joining tubes, creating frames, forming supports, securing scaffold boards, attaching accessories, enabling modular assembly, ensuring load distribution, and offering versatility. These applications contribute to the safety, stability, and efficiency of scaffolding structures.

- Q: Are steel tube couplers resistant to chemicals and solvents?

- In general, chemicals and solvents do not pose a problem for steel tube couplers due to their resistance. Steel, renowned for its exceptional corrosion resistance, is an ideal material for applications where exposure to diverse chemicals and solvents is expected. Nevertheless, the resistance of steel tube couplers may vary depending on the steel type and the specific chemical or solvent employed. To ensure compatibility with particular chemicals or solvents, it is advisable to refer to the manufacturer's specifications or perform appropriate testing.

- Q: Are steel tube couplers resistant to rust and corrosion?

- Yes, steel tube couplers are typically resistant to rust and corrosion. Steel tube couplers are often made with materials such as stainless steel or galvanized steel, which have natural corrosion-resistant properties. Stainless steel contains chromium, which forms a protective layer on the surface of the coupler, preventing rust and corrosion. Galvanized steel, on the other hand, is coated with a layer of zinc, which acts as a barrier against rust and corrosion. Additionally, steel tube couplers can also be treated with anti-corrosion coatings or paints to further enhance their resistance to rust and corrosion. However, it is important to note that no material is completely immune to rust or corrosion, especially in harsh or corrosive environments. Regular maintenance and inspection are still recommended to ensure the longevity and performance of steel tube couplers.

- Q: Are there any specific guidelines for using steel tube couplers in scaffolding systems that need to accommodate different angles or slopes?

- There exist specific guidelines regarding the use of steel tube couplers in scaffolding systems that must accommodate various angles or slopes. In the case of dealing with angles or slopes in scaffolding, it is of utmost importance to verify that the couplers employed are specifically engineered for this purpose. To begin with, it is advisable to employ adjustable steel tube couplers that allow for angular adjustments. These couplers are designed to connect tubes at different angles, affording flexibility in accommodating slopes or angles in the scaffolding system. Furthermore, it is crucial to adhere to the instructions and guidelines provided by the manufacturer for the installation and utilization of the couplers. This includes ensuring the couplers are correctly tightened to guarantee a secure and stable connection. Over-tightening or under-tightening the couplers can jeopardize the integrity of the scaffolding system, thereby posing a safety hazard. Additionally, it is imperative to take into account the load capacity and weight distribution when employing steel tube couplers in scaffolding systems with angles or slopes. The couplers must be capable of withstanding the weight and stress exerted on the structure, particularly when dealing with uneven terrain. Moreover, it is essential to regularly inspect the couplers and the entire scaffolding system for any indications of damage or wear. Any couplers that are damaged or faulty should be promptly replaced to ensure the structural integrity and safety of the scaffolding system. Lastly, it is highly recommended to seek the advice of a qualified engineer or scaffolding professional to ensure the correct design and installation of the scaffolding system, inclusive of the steel tube couplers, in order to accommodate different angles or slopes. Their expertise will aid in ensuring compliance with pertinent safety regulations and scaffolding best practices.

Send your message to us

Frame-Connected Adjustable and Safety Scaffolding

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches