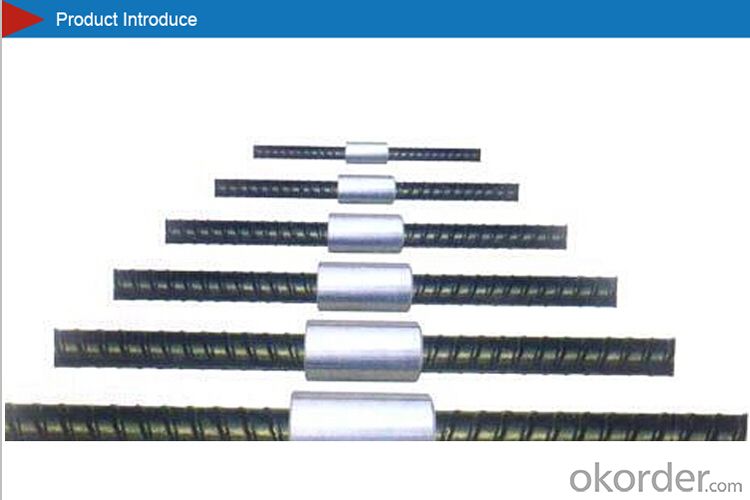

Parallel Thread Rebar Coupler

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Material:45#high quality carbon steel.

2.Application: 12--50mm.

3.High strength,low cost,simple operation.

1#

| Coupler Size | Outer Dia(±0.5mm) | Inner Dia(±0.5mm) | Length(±2mm) | Thread Pitch(mm) | Thread Angle(º) | Weight/Pc(kg) |

| D12 | 19 | 10.28 | 35 | M12*1.75P | 60/75 | 0.036 |

| D14 | 21 | 12.55 | 38 | M14.8*2.5P | 60/75 | 0.068 |

| D16 | 24 | 14.50 | 43 | M16.8*2.5P | 60/75 | 0.099 |

| D18 | 27 | 16.35 | 48 | M18.6*2.5P | 60/75 | 0.125 |

| D20 | 29 | 18.45 | 53 | M20.6*2.5P | 60/75 | 0.180 |

| D22 | 33 | 20.35 | 58 | M22.6*2.5P | 60/75 | 0.205 |

| D25 | 37 | 23.15 | 63 | M26.0*3.0P | 60/75 | 0.317 |

| D28 | 41 | 25.95 | 68 | M28.6*3.0P | 60/75 | 0.399 |

| D32 | 47 | 30.15 | 80 | M32.8*3.0P | 60/75 | 0.640 |

| D36 | 54 | 33.85 | 83 | M36.7*3.5P | 60/75 | 0.900 |

| D40 | 59 | 37.55 | 88 | M40.4*3.5P | 60/75 | 1.099 |

| D50 | 74 | 47.10 | 125 | M50.4*3.5P | 75 | 1.298 |

3#

| Coupler Size | OD(±0.5mm) | Length(±2mm) | Thread Pitch | Thread Angle(º) | G/W(kgs) |

| D14 | 22 | 38 | 2.5 | 75 | 0.068 |

| D16 | 25 | 43 | 2.5 | 75 | 0.099 |

| D18 | 28 | 48 | 2.5 | 75 | 0.125 |

| D20 | 30 | 53 | 2.5 | 75 | 0.180 |

| D22 | 34 | 58 | 2.5 | 75 | 0.205 |

| D25 | 38 | 63 | 3.0 | 75 | 0.317 |

| D28 | 42 | 68 | 3.0 | 75 | 0.399 |

| D32 | 48 | 80 | 3.0 | 75 | 0.640 |

| D36 | 55 | 83 | 3.5 | 75 | 0.900 |

| D40 | 59 | 88 | 3.5 | 75 | 1.099 |

Rebar Coupler Advantages:

----Adopt National Standard 45# igh quality carbon steelas raw meterial.

----High strength, tensile test usually more than 600Mpa,Tensile strength can reach 110%of yiled strength of parent rebar.

----The product has passed ISO9001 International Quality System Certification.

----We can design,produce weldable or other type rebar couper as per customers` requirement.

Tengzhong Machinery Co.,Ltd

A processional manufacture of rebar mechanical splicing equipment,rebar processing machinery,rebar coupler and related products.It is a membership of construction machinery trade of China quality cotrol association.

- Q: Can steel tube couplers be used for both indoor and outdoor scaffolding?

- Steel tube couplers are suitable for both indoor and outdoor scaffolding applications. These couplers are specifically engineered to establish a secure connection between scaffolding tubes, guaranteeing stability and safety. Constructed from durable steel material, they are capable of withstanding diverse weather conditions, rendering them appropriate for both indoor and outdoor deployment. Furthermore, these couplers possess great versatility, allowing for effortless adjustment or dismantling, thus making them an excellent choice for various scaffolding projects in different environments.

- Q: What are the potential risks of using damaged or worn-out steel tube couplers in scaffolding?

- The potential risks of using damaged or worn-out steel tube couplers in scaffolding include compromised structural integrity, increased risk of collapse or instability, potential for accidents and injuries to workers, and failure to comply with safety standards and regulations.

- Q: What is the purpose of a steel tube coupler in scaffolding?

- The main function of a steel tube coupler in scaffolding is to securely and safely connect two steel tubes together. These couplers are commonly utilized in construction projects where scaffolding is necessary to support workers and materials temporarily. Serving as a robust and dependable connection point, the coupler guarantees the stability of the scaffolding structure and enables it to bear the weight and load applied to it. Moreover, it facilitates the easy assembly and disassembly of the scaffolding system, making it a versatile and effective tool for construction projects. Additionally, the steel tube coupler plays a crucial role in maintaining the overall integrity and safety of the scaffolding structure by preventing any movement or separation between the connected tubes. In summary, the purpose of a steel tube coupler in scaffolding is to establish a secure and stable connection that ensures the safety and productivity of construction projects.

- Q: How do steel tube couplers compare to other materials like aluminum or plastic in scaffolding?

- Due to their superior strength and durability in comparison to materials like aluminum or plastic, steel tube couplers are extensively utilized in scaffolding. One of the primary benefits of steel tube couplers lies in their exceptional load-bearing capacity, enabling them to handle heavy weights and provide a stable and secure working platform for laborers. In terms of longevity, steel tube couplers are renowned for their durability. They have a lengthier lifespan when contrasted with aluminum or plastic couplers, making them a cost-effective choice in the long term. Steel resists corrosion, a common concern in scaffolding applications, particularly in outdoor or harsh environments. Furthermore, steel tube couplers offer remarkable stability and safety. They establish a rigid connection between scaffolding tubes, ensuring the structure remains firm and secure. This aspect is particularly vital when operating at significant heights or in areas with substantial wind loads, where a robust and dependable scaffolding system is crucial. Although aluminum and plastic couplers possess their own advantages, such as lighter weight or ease of handling, they often lack the strength and durability provided by steel tube couplers. Aluminum couplers are frequently employed in scenarios where weight is a primary consideration, such as in lightweight scaffolding or for swift assembly and disassembly. Plastic couplers may be suitable for specific applications, but they are generally not recommended for heavy-duty or high-load scenarios. To summarize, steel tube couplers are the favored option in scaffolding due to their exceptional strength, durability, and stability. They offer a dependable and long-lasting solution that ensures the safety of laborers and the efficiency of construction projects.

- Q: Can steel tube couplers be used for scaffolding structures that need to conform to specific architectural or design requirements?

- Yes, steel tube couplers can be used for scaffolding structures that need to conform to specific architectural or design requirements. Steel tube couplers provide a reliable and versatile solution for connecting scaffolding tubes, allowing for various configurations and adaptability to meet specific requirements. Their strength and durability make them suitable for supporting structures in compliance with architectural or design specifications.

- Q: How do steel tube couplers prevent tubes from slipping or rotating?

- By utilizing a combination of mechanical design and friction, steel tube couplers effectively prevent the slipping or rotating of tubes. These couplers have been specifically engineered to establish a secure connection between two steel tubes, guaranteeing their stability under various loads and conditions. The internal gripping mechanism of the coupler is one of its key features in preventing slipping or rotating. This mechanism typically comprises a series of teeth or ridges that are strategically designed to penetrate the surface of the tubes once they are inserted into the coupler. This action creates a robust grip between the coupler and the tubes, effectively preventing any movement or rotation. In addition, the coupler is often fashioned with a snug fit between its inner diameter and the outer diameter of the tubes. This ensures that there is minimal space between the two surfaces, significantly reducing the likelihood of any movement or rotation. Moreover, the coupler is usually crafted from a material with a high coefficient of friction, such as steel. This characteristic means that when the tubes are inserted into the coupler, the friction between the surfaces intensifies, providing enhanced resistance against slipping or rotating. In summary, steel tube couplers are meticulously designed to establish a secure and dependable connection between steel tubes. Through their internal gripping mechanism, snug fit, and high coefficient of friction, they effectively prevent the slipping or rotating of tubes, thus ensuring the stability and integrity of the overall structure.

- Q: Can steel tube couplers be used for connecting scaffolding components other than tubes?

- No, steel tube couplers are specifically designed and engineered for connecting scaffolding tubes. They are not intended for use with any other type of scaffolding components or materials. It is crucial to follow the manufacturer's guidelines and use the appropriate couplers for each specific application to ensure the safety and stability of the scaffolding structure.

- Q: mine just a month old should it still be swollen its only swollen on one bit tho and is antibacterial salt spray ok ive been washing it twice a day since i got it and is it ok that where the bar is theres sum scar tissue im also pushing the bar up and down now not please put my mind at rest!! lol

- My industrial is also about a month old, and it looks perfectly fine. I soak it once a day in a sea salt solution (1/4 teaspoon of SEA salt (no iodine) for 1 cup of warm water) for 5-10 minutes at night. And every morning and night I lather it up with gold dial soap and let it sit there while I brush my teeth, then rinse it clean, and dab it dry with a paper towel - not a cloth towel!! You're also not suppose to move the bar. It can cause an infection and irritation - like the swelling on one bit. Leave the bar alone. Touching it with clean or dirty hands can transfer bad bacterial and really screw up a piercing. Don't sleep on it, keep your hair away from it, and try to keep it out of the sun. It sounds like the scar tissue is the starting of a keloid, which can be from an infection. Clean it as I am, mine has only flared up once in 100+ heat, but it's perfectly fine now. Good luck, don't touch it!

- Q: My cartilage got infected so I wanna take it off, but obv I can't take it off because of he infection, so I was wondering if I can change it to one of those barbells they use to hide your piercings in work and stuff, but that barbell is made of plastic I guess and I have stainless steel on, so I was wondering if Anything could happen or I can just change it

- I had mine accomplished final summer and that they informed me approximately 2 months yet i basically waited 2 weeks, till i had to place a clean one in for artwork...yet once you could dodge doing that do bc the clean ones are particularly extra effective than the orignal and it streches the hollow...and it hurts then gets contaminated

- Q: Are there any specific guidelines for spacing steel tube couplers in scaffolding structures?

- Yes, there are specific guidelines for spacing steel tube couplers in scaffolding structures. The exact spacing will depend on factors such as the load capacity requirements, the type of scaffolding being used, and the specific regulations and standards of the country or region. Generally, couplers should be spaced at regular intervals along the steel tubes to ensure proper stability and structural integrity of the scaffolding system. It is important to consult relevant safety codes, manufacturer's instructions, and qualified professionals to determine the appropriate spacing for steel tube couplers in scaffolding structures.

Send your message to us

Parallel Thread Rebar Coupler

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords