Frame-Connected Scaffolding for Civil Construction and Industrial

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

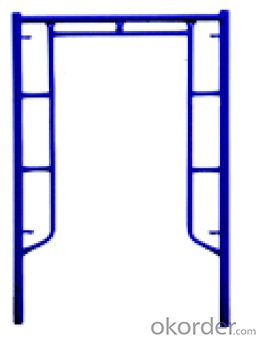

1. Structure of Frame-Connected Scaffolding

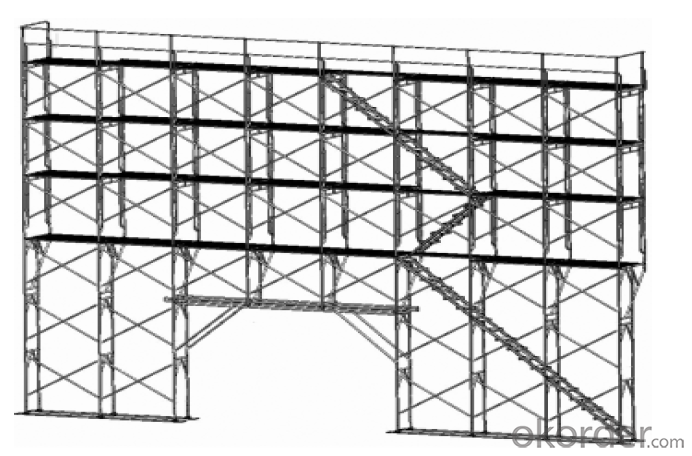

Presented like a shape of door , Frame-connected Scaffolding includes main frame, horizontal frame, cross brace, stage board and adjustable base. In order to display frame with couple system enough, good performance of stability ,firm structure of the whole, easy and fast to assemble and dismantle without any tools, safe working at height especially, and it is ideal material for construction engineering.

It can be widely used for industrial and civil construction and maintenance, such as workshop, large gymnasium, conference& exhibition center conversation, billboard, market, dock, tunnel, subways, etc. used for mobile working platform installation of electrical & mechanical engineering, ship repair and other decoration engineering, for building temporary stand ,with simple roof frame, frame-connected Scaffolding can from temporary dormitory, depot and work shed.

2. Main Features of Frame-Connected Scaffolding

.Reasonable structure, simple assembly, quick operation, safety& reliability.

.Easy to transport and knock down, high efficiently, save massive manpower and resource

.Easy to carry and operate with the weight about 20kg/p

.Assembly& disassembly with hands only to improve the efficiency highly, frame-connected scaffolding of assembly &disassembly saves half of the time than fasten steel-pipe scaffolding, and two third of the time than bamboo scaffolding.

.Widely usage, reasonable and practical, low aggregate cost.

3. Frame-Connected Scaffolding Images

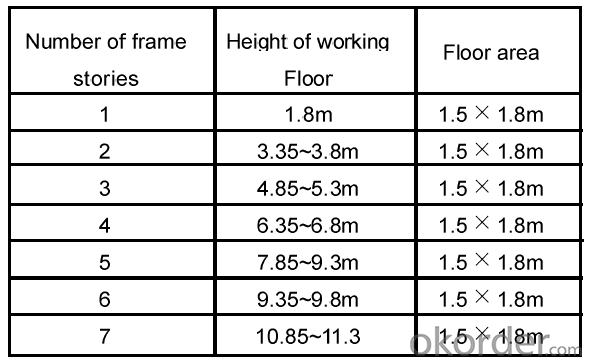

4. Frame-Connected Scaffolding Specification

.Maximum breaking load: 22.2t

.Safe working loads on jack components(safety factor:3.5)

5. FAQ of Frame-Connected Scaffolding

1) What can we do for you?

We can ensure the quality of the vinyl banner and avoid extra expenses for customers.

.We can provide you the professional design team.

.We can provide fashionable and newest styles for you.

.We can design the artwork for you.

. Please feel free to customize.

2) What promises can be done by us?

. If interested in Frame-Connected Scaffolding, please feel free to write us for any QUOTE.

. If printing required, please advise asap because the whole set need much more time to complete.

. Please DO check goods when courier knocks your door and contact us asap if any issue.

3) What about of our after-sale service?

. Response will be carried out in 24hours after receiving any complain or request.

. Frame-Connected Scaffolding cost can be refund after order is confirmed.

. If the products are not based on the requirements, there will be the relevant compensations made for you.

4) What about the package and shipping time?

.Packing: As Customer's Requirements

.Shipping: We have various shipping ways for our customers, such as express which including TNT, DHL, FEDEX, UPS, EMS, etc. ; by air/ sea, and we are VIP of these express.

.Shipping time:

Normally small orders, it just 10-15 business days to arrive your hand; When comes to the customs declaration, it may need 7 days.

Other mass qty of Frame-Connected Scaffolding, we send them out by sea or by air to sea port or air port to save some shipping freight for our customers. By ocean, it may need 45~60days, by air, it may need 25~40days.

- Q: How does a steel tube coupler work in scaffolding?

- A steel tube coupler in scaffolding works by joining two steel tubes together securely, providing a strong and stable connection. It typically consists of two halves with bolts or pins that tighten and hold the tubes in place, ensuring the scaffolding structure remains sturdy and safe for workers.

- Q: What are the common repair or replacement costs associated with steel tube couplers?

- The common repair or replacement costs associated with steel tube couplers may include the cost of purchasing new couplers, labor costs for removing and replacing damaged couplers, transportation costs, and any additional expenses for specialized tools or equipment required for the repair or replacement process. The specific costs can vary depending on factors such as the size and type of couplers, the extent of damage, and the complexity of the installation process.

- Q: How do steel tube couplers ensure proper load distribution and stability in scaffolding structures with irregular or unbalanced loads?

- Steel tube couplers play a crucial role in ensuring proper load distribution and stability in scaffolding structures, even when dealing with irregular or unbalanced loads. These couplers are specifically designed to connect and secure steel tubes, creating a strong and reliable framework. One way steel tube couplers ensure load distribution is by evenly distributing the weight across multiple tubes. Irregular or unbalanced loads can exert different forces on the scaffolding structure, which may cause instability if not properly distributed. By connecting the tubes with couplers, the load is spread out and shared between the tubes, preventing any one tube from bearing an excessive amount of weight. Additionally, steel tube couplers provide stability by effectively transferring forces and loads between the tubes. When irregular or unbalanced loads are applied to the scaffolding structure, there is a risk of twisting or bending that can compromise its stability. However, by using couplers, the forces and loads are transmitted between the tubes, ensuring that the structure remains stable and secure. Moreover, steel tube couplers offer versatility in accommodating different configurations and angles. In scaffolding structures with irregular or unbalanced loads, it may be necessary to connect tubes at various angles or positions. Couplers allow for flexibility in connecting these tubes together, enabling the scaffolding to adapt to the specific load requirements and maintain stability. Lastly, the strength and durability of steel tube couplers play a significant role in ensuring proper load distribution and stability. These couplers are typically made from high-quality steel, which provides the necessary strength and rigidity to withstand heavy loads and maintain structural integrity. The secure connection between the tubes, facilitated by the couplers, prevents any shifting or movement that could compromise the stability of the scaffolding structure. In conclusion, steel tube couplers ensure proper load distribution and stability in scaffolding structures with irregular or unbalanced loads by evenly distributing the weight, transferring forces between tubes, accommodating different configurations, and providing strength and durability. These couplers are essential components that contribute to the safety and reliability of scaffolding systems, allowing them to withstand challenging load conditions.

- Q: Do steel tube couplers provide a secure and stable connection in scaffolding?

- Yes, steel tube couplers provide a secure and stable connection in scaffolding. These couplers are designed to join steel tubes together, creating a strong and rigid structure. They are typically used in construction and industrial applications where stability and safety are paramount. Steel tube couplers are made of high-quality steel, ensuring their strength and durability. They are designed to withstand heavy loads and provide a reliable connection between scaffolding components. The couplers are typically fastened using bolts or pins, which further enhance the stability of the connection. One of the advantages of steel tube couplers is their versatility. They can be used to connect tubes at various angles, allowing for the creation of complex scaffold structures. Additionally, the couplers can be easily adjusted and tightened, ensuring a secure and stable connection. Furthermore, steel tube couplers are commonly used in the construction industry due to their compliance with safety regulations. These couplers are tested and certified to meet specific standards, ensuring that they can withstand the required loads and provide a safe working environment for workers on scaffolding. In summary, steel tube couplers are a reliable and secure method for connecting tubes in scaffolding. They offer stability, strength, and versatility, making them an essential component in constructing safe and sturdy scaffold structures.

- Q: How do steel tube couplers prevent tubes from sliding vertically?

- Steel tube couplers prevent tubes from sliding vertically by providing a secure and tight connection between two or more tubes. These couplers typically consist of a threaded sleeve that is tightened around the tubes, effectively locking them in place and preventing any vertical movement.

- Q: Are steel tube couplers suitable for scaffolding projects involving high winds or seismic activities?

- Yes, steel tube couplers are suitable for scaffolding projects involving high winds or seismic activities. Steel tube couplers are known for their strength and durability, making them a reliable choice for withstanding strong winds and seismic activities. They provide a secure and stable connection between scaffold tubes, ensuring the stability and safety of the scaffolding structure in challenging conditions.

- Q: What are the common warranty terms for steel tube couplers in scaffolding?

- The common warranty terms for steel tube couplers in scaffolding typically include a warranty period of one year from the date of purchase. During this period, the couplers are warranted to be free from defects in material and workmanship. However, the warranty does not cover damage caused by misuse, improper installation, or normal wear and tear. It is important to read and understand the specific warranty terms provided by the manufacturer or supplier of the steel tube couplers.

- Q: What is the typical lifespan of steel tube couplers in scaffolding applications?

- The lifespan of steel tube couplers in scaffolding applications can vary based on multiple factors. Factors such as the quality of the couplers, how often and intensely they are used, and the level of maintenance and care they receive can all impact their lifespan. Typically, when high-quality steel tube couplers are used in standard scaffolding applications, they can last for several years. By regularly inspecting, maintaining, and properly caring for them, they can withstand the demands of construction sites and provide reliable support for extended periods. However, it is important to be aware that certain factors can decrease the lifespan of steel tube couplers. Exposure to harsh environmental conditions, like extreme temperatures, moisture, and corrosive substances, can speed up the deterioration process. Additionally, if the couplers are subjected to excessive loads or misused, their lifespan may be significantly shortened. To ensure that steel tube couplers last a long time, it is crucial to follow the manufacturer's guidelines regarding their usage, storage, and maintenance. Regular inspections should be carried out to identify any signs of wear, damage, or corrosion. If any issues are detected, immediate repairs or replacements should be done to maintain the safety and integrity of the scaffolding system. In conclusion, while there is no set lifespan for steel tube couplers in scaffolding applications, their durability and longevity can be maximized by properly caring for them, conducting regular maintenance, and adhering to safety guidelines.

- Q: How do you ensure proper alignment when connecting steel tube couplers in scaffolding?

- For safety and stability, it is crucial to have proper alignment when connecting steel tube couplers in scaffolding. To achieve this, here are some important steps to follow: 1. Before connecting the steel tube couplers, carefully inspect them to ensure they are in good condition and free from any damage or defects. This will help guarantee a proper fit and alignment. 2. Choose the appropriate type of coupler for the specific connection you are making. There are different types available, such as swivel couplers, sleeve couplers, or putlog couplers, each serving a different purpose. 3. Measure and mark the exact positions where the couplers will be connected on the steel tubes. This will ensure accurate alignment and prevent any errors during the connection process. 4. Clean the surfaces of both the steel tubes and the couplers before connecting them. Removing any dirt, rust, or debris will improve grip and ensure proper alignment. 5. Carefully align the couplers with the marked positions on the steel tubes, making sure to follow the manufacturer's instructions regarding orientation. This will result in a secure and stable connection. 6. Use the appropriate tools to securely tighten the bolts or fasteners once the couplers are aligned. It is important to follow the recommended torque specifications provided by the manufacturer to avoid misalignment and maintain stability. 7. Double-check the alignment after connecting the couplers to ensure they are properly seated and aligned. Look for any signs of misalignment, such as gaps or unevenness, and make necessary adjustments if needed. 8. Regularly inspect the scaffolding structure, including the steel tube couplers, to ensure proper alignment is maintained. Any signs of misalignment, movement, or deterioration should be addressed immediately to prevent accidents or structural failures. By following these steps, you can ensure proper alignment when connecting steel tube couplers in scaffolding, providing a safe and reliable working platform for workers at height.

- Q: Are steel tube couplers compatible with scaffolding systems that require frequent adjustments?

- Yes, steel tube couplers are compatible with scaffolding systems that require frequent adjustments. Steel tube couplers are designed to provide a secure and stable connection between steel tubes in scaffolding structures. They are versatile and allow for easy adjustments as per the specific requirements of the scaffolding system. The couplers can be easily tightened or loosened to accommodate changes in height or position of the scaffolding. This flexibility makes them highly compatible with scaffolding systems that require frequent adjustments to ensure safety, stability, and optimal functionality.

Send your message to us

Frame-Connected Scaffolding for Civil Construction and Industrial

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches