Frame-Connected Scaffolding with Resonable Structure

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

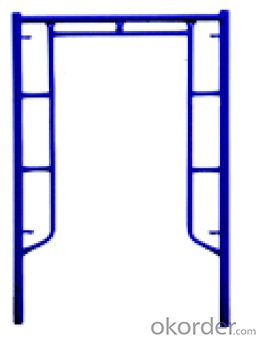

1. Structure of Frame-Connected Scaffolding

Presented like a shape of door , Frame-connected Scaffolding includes main frame, horizontal frame, cross brace, stage board and adjustable base. In order to display frame with couple system enough, good performance of stability ,firm structure of the whole, easy and fast to assemble and dismantle without any tools, safe working at height especially, and it is ideal material for construction engineering.

It can be widely used for industrial and civil construction and maintenance, such as workshop, large gymnasium, conference& exhibition center conversation, billboard, market, dock, tunnel, subways, etc. used for mobile working platform installation of electrical & mechanical engineering, ship repair and other decoration engineering, for building temporary stand ,with simple roof frame, frame-connected Scaffolding can from temporary dormitory, depot and work shed.

2. Main Features of Frame-Connected Scaffolding

.Reasonable structure, simple assembly, quick operation, safety& reliability.

.Easy to transport and knock down, high efficiently, save massive manpower and resource

.Easy to carry and operate with the weight about 20kg/p

.Assembly& disassembly with hands only to improve the efficiency highly, frame-connected scaffolding of assembly &disassembly saves half of the time than fasten steel-pipe scaffolding, and two third of the time than bamboo scaffolding.

.Widely usage, reasonable and practical, low aggregate cost.

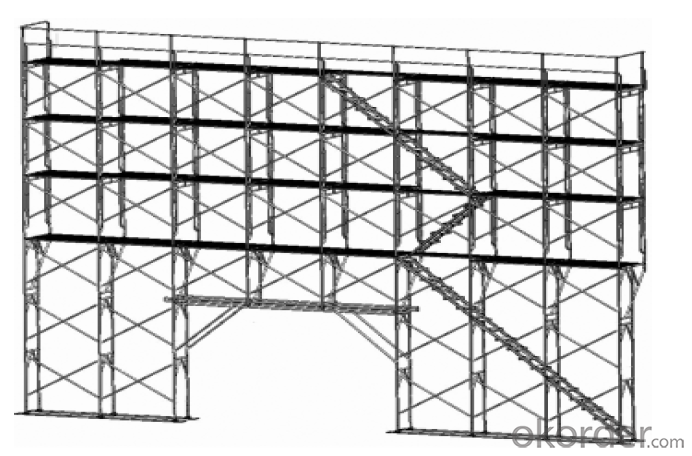

3. Frame-Connected Scaffolding Images

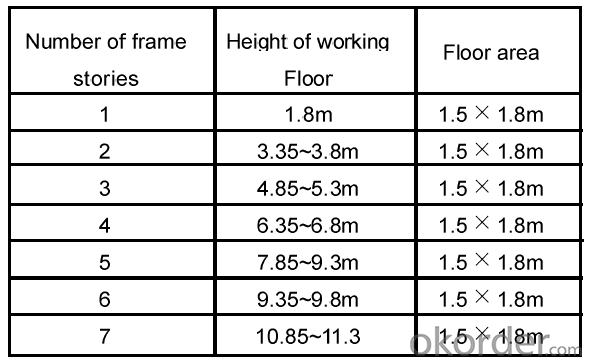

4. Frame-Connected Scaffolding Specification

.Maximum breaking load: 22.2t

.Safe working loads on jack components(safety factor:3.5)

5. FAQ of Frame-Connected Scaffolding

1) What can we do for you?

We can ensure the quality of the vinyl banner and avoid extra expenses for customers.

.We can provide you the professional design team.

.We can provide fashionable and newest styles for you.

.We can design the artwork for you.

. Please feel free to customize.

2) What promises can be done by us?

. If interested in Frame-Connected Scaffolding, please feel free to write us for any QUOTE.

. If printing required, please advise asap because the whole set need much more time to complete.

. Please DO check goods when courier knocks your door and contact us asap if any issue.

3) What about of our after-sale service?

. Response will be carried out in 24hours after receiving any complain or request.

. Frame-Connected Scaffolding cost can be refund after order is confirmed.

. If the products are not based on the requirements, there will be the relevant compensations made for you.

4) What about the package and shipping time?

.Packing: As Customer's Requirements

.Shipping: We have various shipping ways for our customers, such as express which including TNT, DHL, FEDEX, UPS, EMS, etc. ; by air/ sea, and we are VIP of these express.

.Shipping time:

Normally small orders, it just 10-15 business days to arrive your hand; When comes to the customs declaration, it may need 7 days.

Other mass qty of Frame-Connected Scaffolding, we send them out by sea or by air to sea port or air port to save some shipping freight for our customers. By ocean, it may need 45~60days, by air, it may need 25~40days.

- Q: How do steel tube couplers ensure the stability of scaffolding structures?

- Steel tube couplers ensure the stability of scaffolding structures by providing a secure connection between the various components of the scaffolding system. These couplers are typically made of high-quality steel and are designed to withstand heavy loads and forces encountered during construction or maintenance work. One way steel tube couplers ensure stability is by creating a reliable connection between the vertical and horizontal tubes of the scaffolding structure. These couplers are commonly used to join the tubes at right angles, forming a strong and rigid framework. The tight grip of the couplers on the tubes ensures that the structure remains stable and doesn't wobble or sway during use. Moreover, steel tube couplers also allow for flexibility and adjustability in the scaffolding system. They enable the easy assembly and disassembly of scaffolding components, making it possible to customize the structure to fit different job requirements and site conditions. This adjustability ensures that the scaffolding remains stable and secure, regardless of the changes in height, shape, or layout. Additionally, steel tube couplers are designed with safety in mind. They are often equipped with locking mechanisms or bolts to prevent accidental dislodgment or separation of the tubes. This added security minimizes the risk of structural failure and ensures that the scaffolding remains stable throughout the duration of the project. In summary, steel tube couplers play a vital role in ensuring the stability of scaffolding structures. They provide a strong and secure connection between the various components, allowing for flexibility, adjustability, and safety. With the use of these couplers, scaffolding systems can withstand heavy loads, maintain stability, and provide a safe working environment for construction workers.

- Q: Can steel tube couplers be used in different types of scaffolding systems?

- Steel tube couplers have the ability to be utilized in a variety of scaffolding systems. Commonly employed in construction scaffolding, these couplers serve the purpose of connecting and securing steel tubes together. Their design guarantees a dependable and robust connection, thus assuring the stability and safety of the scaffolding structure. Steel tube couplers find application in several scaffolding systems including tube and clamp scaffolding, ringlock scaffolding, cuplock scaffolding, and frame scaffolding. However, it is crucial to ensure that the steel tube couplers employed are compatible with the specific scaffolding system and adhere to the necessary safety standards and regulations.

- Q: Are there any specific weight restrictions or limitations for steel tube couplers?

- Steel tube couplers have specific weight restrictions and limitations. The weight capacity of a coupler depends on its size, design, material, and quality. Manufacturers design and manufacture couplers to meet load requirements and safety standards. Manufacturers provide weight restrictions and limitations in product specifications or guidelines. It is crucial to adhere to these guidelines and not exceed the recommended weight capacity for the coupler to ensure safe and proper functioning. When determining weight restrictions for steel tube couplers, consider factors like the type and application of the coupler, intended load, and overall structural integrity of the system. For specific weight restrictions and limitations based on the application and requirements, consult the manufacturer or a structural engineer.

- Q: How do steel tube couplers compare to other types of scaffolding connectors?

- Scaffolding systems commonly utilize steel tube couplers, which possess several advantages in comparison to other connector types. Firstly, steel tube couplers exhibit exceptional durability, enabling them to withstand heavy loads and harsh weather conditions. Consequently, they prove suitable for prolonged use in construction projects. Furthermore, steel tube couplers offer versatility by facilitating the connection of tubes at various angles. This flexibility allows for adaptable and flexible scaffolding configurations, rendering them particularly ideal for complex or irregular structures. Moreover, steel tube couplers ensure a secure and stable connection. Their design enables them to tightly grip the tubes, thereby guaranteeing the stability and safety of the scaffolding for workers. This feature holds significant importance in high-risk construction environments. Additionally, steel tube couplers boast a relatively easy installation and dismantling process. They do not necessitate specialized tools or skills, leading to time and labor cost savings. Consequently, construction professionals frequently opt for steel tube couplers due to their user-friendly nature. However, it is essential to acknowledge that steel tube couplers may have certain limitations when compared to alternative connector types. For instance, they may not prove suitable for scaffolding systems requiring quick assembly and disassembly. In such cases, more efficient options like pin and ring systems or snap-on clamps may be preferable. In conclusion, steel tube couplers deliver durability, versatility, and stability within scaffolding systems. Though they may not represent the optimal choice for every situation, their benefits make them a favored option within the construction industry.

- Q: Full house scaffolding acceptance should pay attention to what the problem

- Suggested use, near the LED to avoid high temperature, the higher the temperature, LED light fades more serious

- Q: What are the typical installation methods for steel tube couplers?

- Depending on the specific application and requirements, there are various installation methods available for steel tube couplers. One method commonly used is mechanical installation, where the steel tube couplers are simply tightened or screwed onto the ends of the tubes. This method is suitable for temporary installations or situations that require easy dismantling and reassembly. Another option is welding installation, which involves welding the steel tube couplers onto the tubes. This creates a strong and permanent connection, making it ideal for permanent structures or applications that require high load-bearing capacity. Certified welders ensure proper heat distribution and adherence to safety standards during the welding process. In certain cases, adhesive installation methods can be utilized. This entails applying a specialized adhesive or glue to bond the steel tube couplers to the tubes. Adhesive installation methods are typically employed in situations where welding or mechanical installation is not feasible or preferred, such as in sensitive environments or when avoiding heat generation is necessary. It is important to consider that the specific installation method for steel tube couplers may vary depending on factors such as the design of the coupler, the material of the tube, project requirements, and safety regulations. Therefore, it is crucial to consult the manufacturer's instructions and guidelines, and seek professional advice or assistance if necessary, to ensure proper installation and structural integrity.

- Q: Are steel tube couplers compatible with different sizes and types of scaffolding tubes?

- Steel tube couplers can be used with various sizes and types of scaffolding tubes, allowing for a secure and reliable connection. These couplers are specifically designed to create a strong and stable structure by joining scaffolding tubes of different sizes and types. They come in different sizes and configurations to cater to the specific requirements of different scaffolding systems. Whether it involves connecting steel tubes of different diameters or combining steel and aluminum tubes, steel tube couplers offer a versatile and dependable solution. However, to guarantee the safety and durability of the scaffolding system, it is crucial to follow the manufacturer's instructions and adhere to industry standards when using and securing the couplers.

- Q: What are the typical installation methods for steel tube couplers in scaffolding structures?

- Steel tube couplers in scaffolding structures can be installed using different methods. One common approach is the "putlog" or "single coupler" installation. Here, a spanner or wrench is used to tighten the coupler securely onto a single scaffold tube, establishing a connection that contributes to the stability of the scaffold. Alternatively, the "double coupler" installation involves connecting two scaffold tubes with two steel tube couplers, one on each side. By tightening the couplers, a strong connection is formed between the tubes, enhancing the overall stability of the scaffold. The "swivel coupler" installation is another widely used method. This type of coupler permits a 360-degree rotation, allowing the scaffolding to be set up at different angles and configurations. Swivel couplers are particularly useful in situations where adaptability and flexibility are necessary. Lastly, the "sleeve coupler" installation method entails sliding a steel tube through a sleeve coupler, which is then tightened to secure the connection. This method is typically employed when joining two tubes end-to-end to create longer scaffold spans. In summary, the installation of steel tube couplers in scaffolding structures involves securely tightening the couplers onto scaffold tubes to establish strong and stable connections. These methods guarantee the safety and reliability of the scaffolding structure during construction or maintenance projects.

- Q: Can steel tube couplers be used in scaffolding projects with corrosive environments?

- In scaffolding projects with corrosive environments, it is possible to utilize steel tube couplers. However, it is crucial to carefully choose the appropriate steel type and implement proper protective measures. To combat corrosion, stainless steel couplers or galvanized steel couplers are commonly employed due to their superior resistance compared to regular steel. These couplers are specifically designed to endure the corrosive effects of substances like saltwater or chemicals that may exist in the surroundings. Moreover, augmenting the longevity of the couplers can be achieved by applying corrosion-resistant coatings or paints that act as a barrier. Regular inspections and maintenance are also essential to promptly identify any signs of corrosion and take necessary actions to prevent further damage.

- Q: Can steel tube couplers be used in scaffolding projects with limited overhead clearance?

- Steel tube couplers are frequently utilized in scaffolding systems to join and secure steel tubes. They establish a robust and dependable connection, guaranteeing the stability and safety of the scaffolding structure. In projects where there is restricted overhead clearance, steel tube couplers offer numerous benefits. Firstly, they possess a compact design and do not necessitate much vertical space, rendering them suitable for such projects. Secondly, they can be effortlessly adjusted and secured in confined areas, enabling the efficient assembly and disassembly of the scaffolding structure. Furthermore, steel tube couplers exhibit exceptional durability and can withstand substantial loads, ensuring the stability and safety of the scaffolding system even under challenging circumstances. Their versatility and user-friendly nature render them a popular choice for scaffolding projects with limited overhead clearance.

Send your message to us

Frame-Connected Scaffolding with Resonable Structure

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches