Detailed Product Description/

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Detailed Product Description

1.convenient scaffolding system

2.industrial buildings and civil buildings

Convenient Ring - Lock Scaffold Formwork For Industrial, Civil Buildings

Description:

Brief introduction

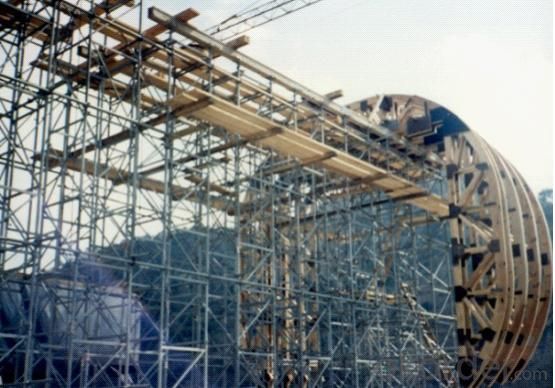

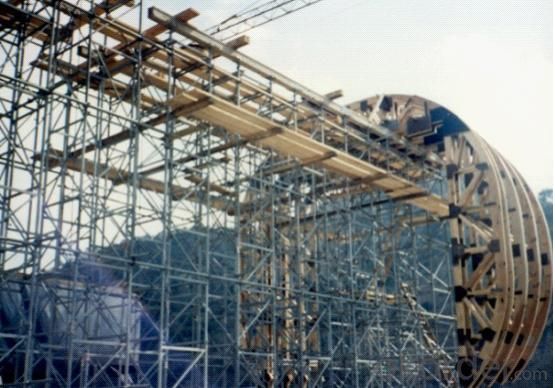

A convenient scaffolding system, especially for load-bearing support, its structure is simple and reasonable, its operation is easy and flexible, and the system is widely used in industrial buildings and civil buildings.

Competitive advantage

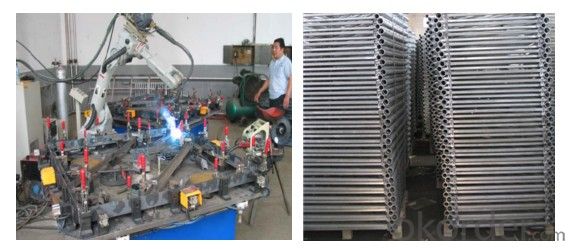

①. Product standardization, produce cost is lowered.

As the picture left shown, the standard is auto-welded; all the distance between cross plates of standards with different length is 500mm, which makes the auto-welded working method be easily achieved.

②. Spatial tower assembly guarantees high load-bearing capacity.

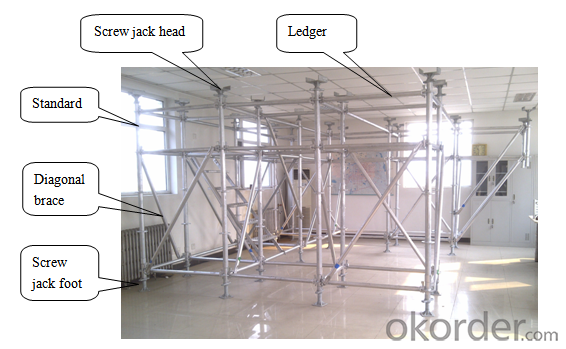

The main body of RL-scaffolding system is consisted of standard, ledger, diagonal ledger, and diagonal brace. The system forms a whole spatial frame structure that guarantees its high load-bearing capacity.

③.Smart joint design guarantees safe application and easy operation.

As the picture below shown, the “connect head” stuck in the position of cross plate with correct hole, then fix the pins tightly with a hammer, after that, you finish the whole connection work. The joint is safe and firmly.

Applications

- Q: PLEASE HELP!!

- Let tension in the futher cable be T, taking moment abt cable nearer to washer T * 5.1 = 50 g * [5.1/2] + 83g * 1.1 T = 1156.62 N ---answer T1 + T = 50g + 83 g T1 = 148.11N answer tension in cable nearer washer

- Q: What are the typical sizes and dimensions of steel tube couplers for scaffolding?

- The typical sizes and dimensions of steel tube couplers for scaffolding vary depending on the specific requirements of the project. However, commonly used sizes include 48.3mm outside diameter and 4mm wall thickness for the main tubes, and 48.6mm outside diameter and 3.2mm wall thickness for the couplers. These dimensions ensure a secure and sturdy connection between the scaffolding tubes, providing stability and safety.

- Q: Can steel tube couplers be used in scaffolding projects with complex geometries?

- Yes, steel tube couplers can be used in scaffolding projects with complex geometries. Steel tube couplers are versatile and can be used to connect tubes at various angles, allowing for the creation of scaffolding structures that can adapt to complex shapes and configurations.

- Q: Chillingworth sees Hester when she is being put on display for the town to see that she is an adulteress. What is Hester on? Is Hester on a scaffold or a pillory, or is there not a difference?

- She is ON a scaffold IN a pillory. A scaffold is a platform. A pillory (also known as the stocks) is a device that has a large hole in the center and two smaller holes off-center. The larger hole is for the person's head and the smaller holes are for the person's hands. When Hester was placed in the pillory, the pillory was sitting atop a scaffold. The pillory is elevated so that the townspeople can get a good view - the entire point of this punishment is public humiliation.

- Q: How do steel tube couplers affect the overall stability and sturdiness of scaffolding towers?

- Steel tube couplers play a crucial role in enhancing the overall stability and sturdiness of scaffolding towers. These couplers are used to connect different tubes and components, ensuring a secure and rigid structure. By effectively distributing the load and providing a tight connection, steel tube couplers prevent any movement or shifting of the scaffolding, which helps maintain its stability and structural integrity. Additionally, their robust construction and reliable grip ensure that the scaffolding tower remains sturdy and can withstand heavy loads and external forces, making them essential for safe and reliable construction projects.

- Q: Are steel tube couplers suitable for outdoor scaffolding applications?

- Yes, steel tube couplers are suitable for outdoor scaffolding applications. Steel tube couplers are designed to provide a secure and stable connection between scaffolding tubes, making them ideal for outdoor construction projects. They are made from high-quality steel that is durable and resistant to environmental conditions such as weathering, corrosion, and UV radiation. Steel tube couplers also have a high load-bearing capacity, ensuring the safety and stability of the scaffolding structure. Additionally, they are easy to install and dismantle, making them convenient for outdoor applications where mobility and flexibility are important. Overall, steel tube couplers are a reliable and suitable choice for outdoor scaffolding applications.

- Q: I had the scaffold piercing done around 8 weeks ago give or take.Im not sure if the piercer done it 100% correct. the upper part is fine - altho I have a small lump inside.But the lower part is in the thickest part of the ear. Its getting a layer of skin (small) over the bar now.Is this right?Also, it has a studio titanuim bar in at the moment, the top is really hurting and a bit swolen so I guess its getting infected? Ive ordered 2 standard rings to fit to try and heal by itsself (I had the bar put in right away)Is it ment to hurt that much after this long?

- Titanium is a good choice...Make sure you keep the area clean. I do not recommend changing the bar until it has completely healed... the piece of skin could a keloid scar forming. go back to the piercer and get tehm to check it and they will let you know.. It's hard to say without looking at it.. good luck..

- Q: In the hands of a few projects, to use steel pipe, fasteners, scaffolding, location in Luotian, open the first project is twenty thousand square, high eight, duration of eight Months, there are other projects to several thousand tons. I think this is a chance. what should I do? Thank you. More

- Need, the fire limit is half an hour, need to apply fire retardant coating.

- Q: Are steel tube couplers compatible with other scaffolding components?

- Yes, steel tube couplers are compatible with other scaffolding components. They are designed to connect tubes and provide a secure and stable connection, allowing for the assembly of various scaffolding structures.

- Q: Can steel tube couplers be easily disassembled from scaffolding structures?

- It is indeed possible to easily disassemble steel tube couplers from scaffolding structures. These couplers are specifically engineered to ensure a secure link between steel tubes in scaffolding systems. Typically, they consist of two components that can be effortlessly connected and disconnected using a straightforward tightening mechanism. As a result, scaffolding structures can be rapidly and efficiently assembled and disassembled. By utilizing basic tools like a wrench or a spanner, the couplers can be conveniently loosened and removed from the steel tubes. This simplicity in disassembly offers the flexibility to adjust or relocate the scaffolding structure as required.

Send your message to us

Detailed Product Description/

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords