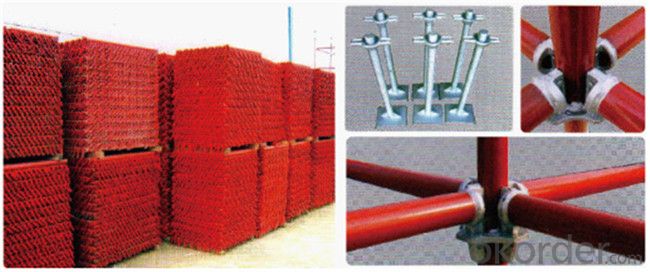

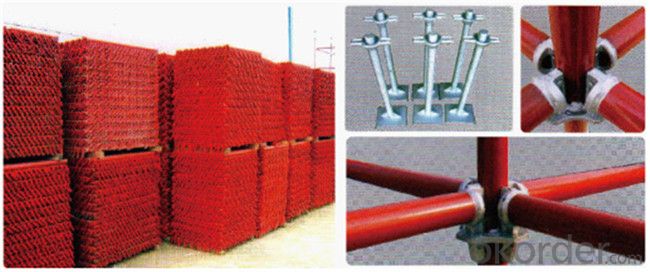

Pulley-clip Scaffolding

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Pulley-clip Scaffolding

Features:

①Safe & Stable The pulley-clip scaffold has perfect mechanical properties:The theoretical data of the eccentric distance of the vertical pole joints of pulley-clip scaffold is zero,which improves the axial compressive strength of the vertical poles,plays the mechanical properties of the material and impressive entire stability.Furthermore,the tensile forces and pressures on each joint of the pulley-clip scaffold in operation are in reasonable distribution state,which ensures the pulley-clip scaffold has perfect rigidity and entire stability.

②Efficient & Economic By the statistics,the connecting and dismounting efficiency of pulley-clip scaffold is 6-8 tines higher than coupler scaffold,5-7 times higher than frame scaffold,3-4 times higher than cup-lock scaffolding.The steel tube scaffold does not have any special locking part structurally, which greatly improves the locking reliability..The connecting and dismounting speed is fast with distinct effect in high rise and high altitude operation.Simple process saves construction time and effort,and reduces labor intensity.

③Ultra-low Loss Realize that the steel scaffold does not have moving spare parts strcturally and solve the easy loss,

Easy damage and uneasy transportation problems of the spare parts of the scaffold. The building and dismounting are safer with more distinct role in high-rise and high altitude operations. The lost and stolen rate is below 0.5%.

④Wide Application It adapts to the technical characteristics and economic characteristics of the engineering, can be used independently and solves the problem of joint use with the cup lock scaffold, which provides convenience in technology and economic benefit for the building site which has used cup lock scaffold in large amount to use pulley-clip scaffold.

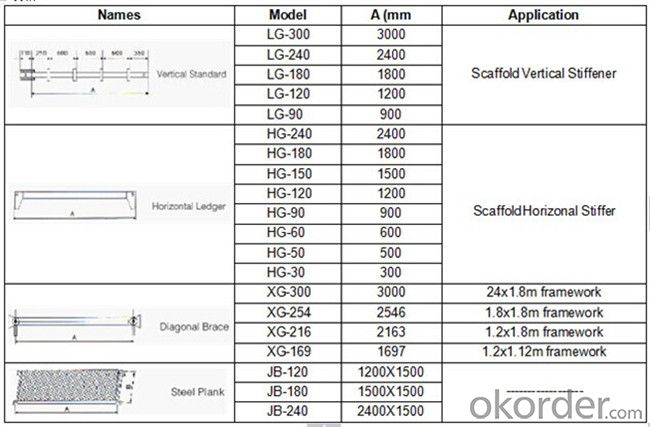

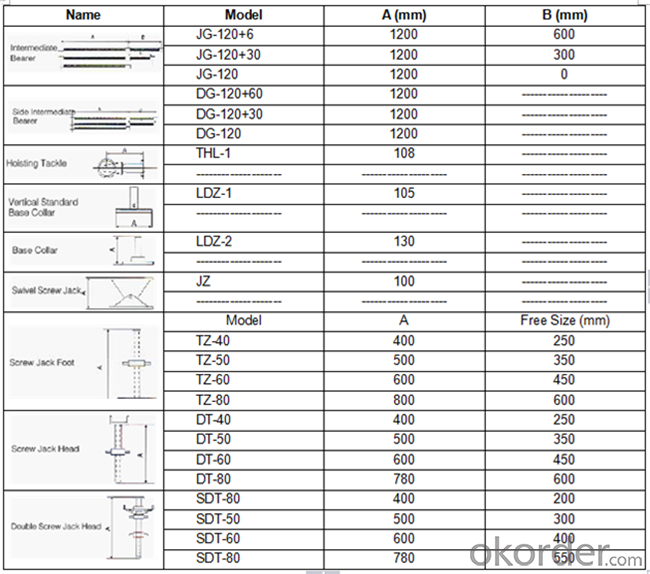

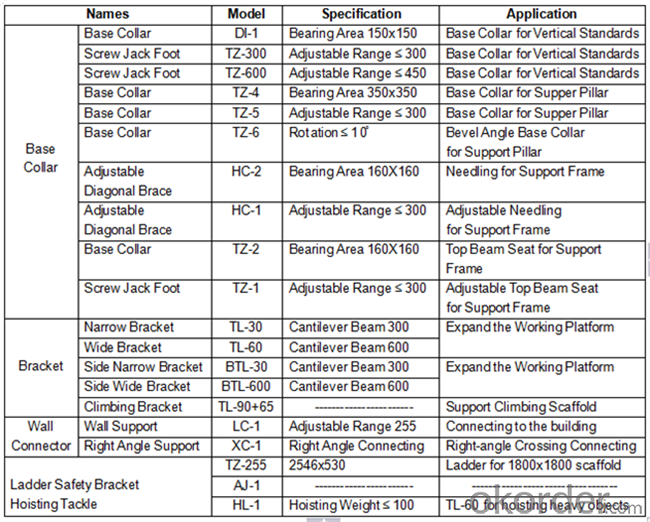

Parameters:

- Q: What safety precautions should be taken when using steel tube couplers?

- To ensure the safety of both workers and the overall structure, it is important to take several safety precautions when using steel tube couplers. Here are some essential safety measures to follow: 1. Personal Protective Equipment (PPE): Workers involved in installing or handling steel tube couplers must wear appropriate PPE, including safety helmets, goggles, gloves, and steel-toe boots. This will protect them from potential hazards such as falling objects, sparks, or accidental contact. 2. Training and Competence: Only trained and competent workers should be engaged in the installation and use of steel tube couplers. They should have a thorough understanding of the couplers' purpose, proper installation techniques, and potential risks associated with their use. 3. Inspections and Maintenance: Regular inspections should be conducted to ensure that the steel tube couplers are in good condition and free from defects or damage. If any issues are identified, the couplers should be immediately replaced or repaired. Proper maintenance should also be performed to prevent deterioration or weakening of the couplers. 4. Load Capacity and Limitations: Understanding the load capacity and limitations of the steel tube couplers being used is crucial. Exceeding the recommended load capacity can result in structural failure, which is extremely dangerous. Therefore, it is important to consult the manufacturer's guidelines and specifications to ensure the couplers are used within their intended limits. 5. Proper Installation: Correct and secure installation of steel tube couplers is essential. This includes ensuring proper tightening of the couplers and fully inserting the tubes into them. Care should be taken to align the tubes correctly to avoid misalignment or weak points. 6. Stability and Bracing: In applications where stability is vital, such as scaffold structures, appropriate bracing and stability measures should be implemented when using steel tube couplers. This will help prevent accidental collapse or movement of the structure during use. 7. Regular Inspections: Regular inspections of the steel tube couplers and the overall structure should be carried out by competent individuals to identify any signs of wear, damage, or structural instability. Prompt action should be taken to address any identified issues. By adhering to these safety precautions, the risk of accidents, injuries, and structural failures associated with the use of steel tube couplers can be significantly reduced. This will ensure a safe working environment and a secure structure.

- Q: ... the two methods are similar

- Scaffolding method is not mathematical method. It's just the way to provide people some knowledge in working on the problem. Well, to use the standard algorithm, see this guide.

- Q: heyi got my scaffold (industrial) piercing done a while ago and it has had enough time to heal but unfortunatley i cant unscrew the balls on the bar help????what can i do?

- i had the same problem. it took me FOREVER, but i finally got them off. trying putting like cloth of something over your hand so it's not as slippery. it'll take a long time, but they will eventually come off.

- Q: Are steel tube couplers resistant to fire?

- Yes, steel tube couplers are generally resistant to fire. The high melting point of steel makes it able to withstand high temperatures for a prolonged period, minimizing the risk of structural failure during a fire. However, it is important to note that the exact fire resistance may vary depending on the specific design, coating, and quality of the steel tube couplers.

- Q: Can steel tube couplers be used in high-load scaffolding applications?

- Yes, steel tube couplers can be used in high-load scaffolding applications. Steel tube couplers are strong and durable, making them suitable for supporting heavy loads in scaffolding structures. They provide a secure and reliable connection between steel tubes, ensuring the stability and safety of the scaffolding system even under high loads.

- Q: Can steel tube couplers be used in scaffolding systems that need to accommodate special access requirements?

- Indeed, steel tube couplers are capable of being utilized in scaffolding systems that necessitate the accommodation of distinctive access prerequisites. These versatile steel tube couplers possess the ability to connect scaffolding tubes at diverse angles and positions, thereby enabling the creation of customized scaffolding structures. This adaptability renders them suitable for scaffolding systems that require adjustment to cater to exceptional access requirements, including facilitating entry into irregularly shaped or difficult-to-reach areas. Moreover, the strength and dependability of steel tube couplers are well-regarded, guaranteeing the stability and safety of the scaffolding system, even when confronted with special access demands.

- Q: Can steel tube couplers be used in scaffolding systems with different load capacities?

- Steel tube couplers can indeed be used in scaffolding systems with different load capacities. These couplers are designed to securely connect steel tubes together, forming the structure of the scaffolding system. They are typically made from high-quality steel, ensuring strength and durability. When it comes to load capacity, it is important to consider the specific type and grade of steel tube couplers being used. Different couplers may have varying load-bearing capacities, so it is essential to select the appropriate couplers based on the expected loads in the scaffolding system. It is also crucial to ensure that the scaffolding system is designed and constructed in compliance with relevant safety standards and regulations. This includes considering factors such as the maximum load capacity of the scaffolding, the type of loads it will be subjected to (such as personnel, materials, or equipment), and any additional safety measures required. In summary, steel tube couplers can be used in scaffolding systems with different load capacities. However, it is important to carefully select couplers with appropriate load-bearing capacities and ensure compliance with safety standards to ensure the structural integrity and safety of the scaffolding system.

- Q: Can steel tube couplers be used in scaffolding projects with overhead structures?

- Yes, steel tube couplers can be used in scaffolding projects with overhead structures. Steel tube couplers are designed to provide a secure connection between scaffolding tubes, ensuring stability and safety. They can be used to construct scaffolding systems that can support overhead structures, such as roofs or ceilings, effectively.

- Q: Are steel tube couplers suitable for scaffolding projects in seismic zones?

- Yes, steel tube couplers are suitable for scaffolding projects in seismic zones. Steel tube couplers are designed to provide a secure and rigid connection between scaffolding tubes, ensuring stability and safety. They are capable of withstanding seismic forces and can be used effectively in areas prone to earthquakes.

- Q: How do steel tube couplers contribute to the overall stability and strength of scaffolding?

- Steel tube couplers play a crucial role in enhancing the overall stability and strength of scaffolding structures. These components are used to securely connect and join steel tubes together, creating a rigid and stable framework. Firstly, steel tube couplers provide a reliable and strong connection between tubes, ensuring that the scaffold structure remains stable and can support heavy loads. The couplers grip the tubes tightly, preventing any movement or slippage, even under significant pressure. This secure connection is essential for maintaining the integrity of the scaffold and ensuring the safety of workers who rely on it. Moreover, steel tube couplers distribute the weight and load evenly across the scaffold structure. By connecting the tubes at various points, the couplers help to transfer the load from one tube to another, effectively distributing the weight throughout the scaffold. This distribution of weight prevents any single tube from bearing excessive stress, reducing the risk of failure or collapse. Additionally, steel tube couplers enable the scaffold to be easily assembled and disassembled, providing flexibility and convenience. The couplers allow for quick and simple connections between tubes, facilitating efficient construction and dismantling processes. This ease of assembly not only saves time and labor but also contributes to the stability of the scaffold by ensuring that all components are securely connected. Furthermore, steel tube couplers are highly durable and resistant to corrosion, making them ideal for long-term use in various weather conditions. Their robust construction ensures that they can withstand the rigors of construction sites, providing a reliable connection between tubes for extended periods. In conclusion, steel tube couplers significantly contribute to the overall stability and strength of scaffolding structures. They provide a secure connection between tubes, distribute the weight evenly, facilitate easy assembly, and offer durability and resistance to corrosion. These factors combine to enhance the safety and reliability of scaffolding, making steel tube couplers an essential component in construction projects.

Send your message to us

Pulley-clip Scaffolding

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords