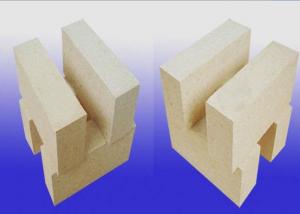

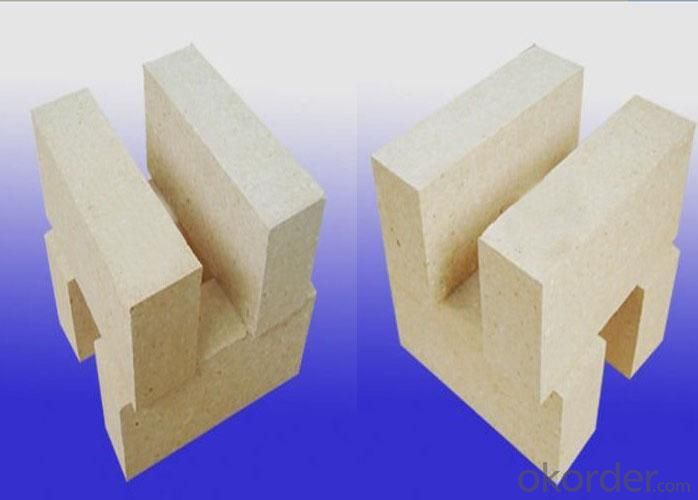

Refractory AKZ-85 Alumina Bubble Brick

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2 Tons m.t.

- Supply Capability:

- 5000 Tons per Month alumina bubble brick in stock m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Features of Refractory AKZ-85 Alumina Bubble Brick

1.High compressive strength

2.Excellent thermal shock resistance

3.High thermal efficiency of the kiln

Description of Refractory AKZ-85 Alumina Bubble Brick

alumina bubble brick refractory brick bricks have high-alumina bauxite powder and refractory clay as raw materials and some inflammable additions, shaped by tamping or extrusion pressing and fired in high-temp tunnel kiln after being dried.

alumina bubble brick refractory bricks have three brands in accordance with their bulk densities, which are decided by the amount of the inflammable additions. alumina bubble brick refractory bricks with large bulk density have the features of high mechanical strength and small change of load at a high temperature.

Used alumina bubble brick Features

·High compressive strength

·Excellent thermal shock resistance

·Able to lower the heat capacity of the furnace wall

·High thermal efficiency of the kiln

·All types of products available as customers require.

Application of alumina bubble brick

alumina bubble brick can be Used in heat-insulating layers and furnace linings of thermal equipment, such as, roller kilns ceramics, heating furnaces petrochemical reforming, reforming furnaces, soaking ptis metallurgy and blast furnaces.

Physical and chemical index of Refractory AKZ-85 Alumina Bubble Brick

Item | AKZ-85 | AKZ-90 | AKZ-99 | |

Chemical composition | Al2O3 | ≥85 | ≥90 | ≥99 |

SiO2 | ≤13 | ≤8 | ≤0.2 | |

Fe2O3 | ≤0.5 | ≤0.5 | ≤0.5 | |

Apparent Porosity% | 58-62 | 58-62 | 58-62 | |

Bulk Density g/cm3 | 1.4-1.7 | 1.4-1.7 | 1.4-1.7 | |

Cold Crushing Strength Mpa | ≥12 | ≥10 | ≥9 | |

0.1Mpa Refractoriness Under Load T0.6 °C | ≥1650 | ≥1700 | ≥1700 | |

Permanent Linear Change On Reheating

(%)1500°CX2h | ±0.3 | ±0.3 | ±0.3 | |

20-1300°C Thermal Expansion % (x 10-6) | 0-7.8 | 0-8.0 | 0-8.6 | |

Thermal Conductivity(Average 800°C) W/(M.K) | ≤0.8 | ≤1.3 | ≤1.5 | |

Max Service Temperature °C | 1680 | 1700 | 1800 | |

- Q: I started to open a company. We are doing transportation and building materials. Think of a company name. Would like to ask you what name should you register the capital can be less? Can tax less? As far as possible can not be separated from the transport of building materials this lazy rough scratch Nao calcium stubble water long class. What kind of tax should be reported? The Please do not send some tax law in general? The company set up conditions ah ... ... straightforward some ... ... more

- As for the tax less, there are votes on the report no votes do not report, a small scale on it How much tax to see your billing situation? (You do not open the case of value-added tax votes) tax evasion is not a good habit

- Q: General taxpayer commerce company sales of cement, building materials products should be handed a few points

- Article 2 VAT rate: The taxpayer shall sell or import the goods in accordance with the provisions of subparagraphs and of this Article, the tax rate shall be 17%

- Q: I primed my CPVC pipe with the purple stuff and then used PVC cement instead of CPVC cement. Is this going to be a problem? What is the risk?

- This Site Might Help You. RE: Used PVC cement for CPVC - ok? I primed my CPVC pipe with the purple stuff and then used PVC cement instead of CPVC cement. Is this going to be a problem? What is the risk?

- Q: I have 300sq feet of yard space that's infested with worms and all sorts of creeters. I wanna cover 100 ft of. This yard in cement. And grow nice healthy grass behind it. Hope yall can help me out

- First off, its concrete, not cement. Cement is only an ingredient in concrete. Second of all, whats wrong with worms and critters. Yikes, without them we wouldn't have food, our eco system would collapse, and we would all die. Third of all, weeds can be used as nicely as lawns, achieving that perfect piece of lawn is ugly and harsh on our enviroment. Of course you can concrete a section of your yard, you level and grade it and then have it poured. To achieve you perfect lawn apply toxic herbicides and pesticides, continue to pollute our soils and waterways further, kill off beneficial insects such as bees and bugs, let those poisions run off into our water ways, kill our fish, and contribute to the demise of the eco system just a little bit further. Then go ahead and plant some grass seed that doesn't even thrive in you climate, then you will need to pump tons of water and fertilizer into monthly to achieve that perfect look. Then sit back and enjoy your little piece of toxic heaven. Now enjoy it a lot, because you will be enjoying for you great grand children as well, because they won't have a planet to live on. A conciseness person would think to themselves, why not just clean it up by hand and plant a garden, feed you family, feed a friend, feed the neighbor hood, and take care of your own just a little bit and conquer your complete dependence on the grocery store.

- Q: i hire a contractor to replace and removed the old siding form my house. i have seen siding install before and there is normally an woord frame or plywood that is underneat the siding. the contractor stated that is no needed. and based on that he refused to continue with the work. i then proceeded to put a stop payment on the downpayment what are my options now! can i hired someone else to do the work without bein held liable for his expenses?

- you do not need ply wood only a breather type paper barrier and all is well. Have you read up on the specs for the product. You have a problem with the contractor though. Self professed home experts are the worst . They seem to know better than an experienced contractor. You have some aplogising to do. I hope he accepts it . you are liable

- Q: I am building a box in the ground and need it water-proof.Whats the best mixure cement/sand, or should I use concrete?What differs cement/concrete? And how do you make it strong from cracking without steel enforcement?

- About the only suggestions I can give you is to put a descent amount of granite gravel in with the cement and to mix it a little on the dry side. If you notice, old concrete from around the 1940's and earlier tends to hold up better than newer concrete. If you look at the old concrete in relation to new concrete it has larger gravel in it and it has more granite gravel in it. You don't want to put gravel such as limestone in it. Limestone will cause the concrete to break up during winter. A trick I learned off of a friend of mine who worked for a concrete company is to mix concrete on the dry side. A dryer concrete mix instead of a soupy one will tend to be stronger and last longer.

- Q: advisable storage method of cement?

- I know your friend and she (if I'm correct) is very much missinformed as to storage technique. As much as we both love her, (she's a fine lass) toss the advice. Your little friends need open air! There should be a small hook just under the hairline, on the neck, in the back...Find a comfy spot in the sun and hang 'em...they'll love you more for it.

- Q: l need to know- thankyou,xx jo

- By volume; sand then cement and finally water. Try pouring some sand into the water and see it sink to the bottom. Do the same with cement and youll see the same only slower

- Q: I was wondering how the heck the pour cement onto the river to make the pillar for the bridge??

- They can use very large pipes pounded into the bottom, but most importantly cement will harden under water as it is a chemical process, not a drying process.

- Q: Is there a difference between the two?

- In addition to the excellent answer from hamrrfan, I would add that concrete is typically much stronger than cement due to the addition of the aggregate.

1. Manufacturer Overview

| Location | Henan,China (Mainland) |

| Year Established | 2007 |

| Annual Output Value | US$2.5 Million - US$5 Million |

| Main Markets | North America; South America; Eastern Europe; Southeast Asia; Africa; Oceania; Mid East; Eastern Asia; Western Europe; Central America; Northern Europe; Southern Europe |

| Company Certifications | business license |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai,Qingdao,Tianjin |

| Export Percentage | 51% - 60% |

| No.of Employees in Trade Department | 6-10 People |

| Language Spoken: | English, Chinese, Spanish, Japanese, Portuguese, German, Arabic, French, Russian, Korean, Hindi, Italian |

| b) Factory Information | |

| Factory Size: | 10,000-30,000 square meters |

| No. of Production Lines | 2 |

| Contract Manufacturing | OEM Service Offered Design Service Offered |

| Product Price Range | High and/or Average |

Send your message to us

Refractory AKZ-85 Alumina Bubble Brick

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2 Tons m.t.

- Supply Capability:

- 5000 Tons per Month alumina bubble brick in stock m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords