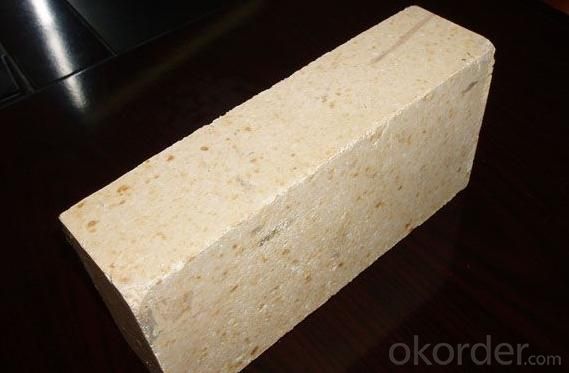

High Alumina Casting Steel Refractory Brick

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 11 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Specifications

1. AL2O3 : 40%-75%.

2. Can according to customers' requirements.

3. Used for Steel industry casting steel.

Specifications

1. AL2O3 : 40%-75%.

2. Can according to customers' requirements.

3. Used for Steel industry casting steel.

Casting steel refractory brick,Refractory brick for Casting steel,Casting steel brick

Features and advantages:

1. High refractoriness.

2. Good spalling resistance and wear resistance.

3. Good corrosion resistance.

4. Good thermal shock resistance.

5. High mechanical strength.

6. High-temperature creep rate is low.

7. Good volume stability at high temperature.

Physical and chemical indicators:

- Q: How much is one ton of high alumina refractory brick?

- High alumina refractory brick according to the different content of AL2O3 is divided into grade, grade one and grade two, and grade three high aluminum brick, Zhengzhou Kang Hui refractories factory price in 800-1900 yuan / ton, stable quality, are exported to the domestic and foreign markets.

- Q: What is the standard size of high alumina brick?

- Standard brick: 230 x 115 x 65; four points: 230 x 115 x 40; three points: 230 x 115 x 30; 150 x 120: Brick gable. Light weight brick 1 to 1.7 kilograms; heavy clay superscript brick weighs 3.75 kilograms; light 30 plates 0.79 kilograms; light 40 plates, 1.05 kilograms.

- Q: Aluminum content 38, silicon content 55 What refractory bricks?

- Semisilica brick: the content of Al2O3 is 15% ~ 30% of aluminium silicate refractory products. Manufacturing products are semi silica quartz containing impurities or native clay kaolin, refractory clay or kaolin beneficiation tailings and the pyrophyllite

- Q: What are the characteristics of high alumina bricks?

- The product has the advantages of high temperature, little creep, strong corrosion resistance and good thermal shock resistance, and is suitable for large and medium-sized high-temperature kilns and other energy consuming industries, such as chemical industry, electric power industry, etc.

- Q: What are the alloy wear resistance materials?

- Alloy wear-resistant materials from different manufacturers different components in Beijing Naimo company as an example, the following alloy wear resistant material:1: Ni Cr alloy wear-resistant material2: chrome carbide wear-resistant material3: high manganese alloy wear-resistant material4: tungsten carbide alloy wear-resistant material5: nickel tungsten alloy wear-resistant material

- Q: Which is better, the soft core or the hard core?

- The use of each of the single core copper wire with low line, 1.5 square with cap line home, socket 2.5 square, air conditioning to walk alone line 4 square can, when the terminal box into a socket with leakage protection switch, prevent overload and short circuit.

- Q: What kinds of minerals are there in the five major categories of ore crystal chemistry?

- Halide. A few species, about 120 species, accounting for only 0.1% of the earth's crust. Most of them formed in the surface conditions, forming a salt mineral, containing less pigment ions, light color, low hardness, generally less than 3.5. Common mineral halite (NaCl), potassium (KCl), fluorite (CaF2) etc..

- Q: Corundum, high alumina and fireclay refractory difference is what

- They differ in that the alumina content is different, and the content is in order: corundum > high alumina > clay.

- Q: What's the weight of the refractory bricks?

- Fireclay refractory bricks: 3.4kg-3.8kg - according to the quality of raw materials, prices ranging from 1 yuan to 2.7 yuan, high alumina refractory brick: three, high aluminum in 3.9kg or so. Ordinary T-3 firebrick weight calculation method: 230*114*65*2.2/2.1.

- Q: What should be used as binder for making high alumina bricks?

- Bond for making high alumina brick: soft clay has good plasticity, so the high alumina brick is usually made of soft clay as bond. However, the free Al2O3 free SiO2 and bauxite clinker clay in under 1200 degrees occurred two times of Mullization reaction, generate large volume expansion, silicon porosity, strength reduction. Therefore, the amount of clay powder in the ingredient should be no more than 5%.

Send your message to us

High Alumina Casting Steel Refractory Brick

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 11 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords