PVC compound for VDE standard wires and cables

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 3000 Tons kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PVC compound for VDE standard wires and cables

I. Type and application

Type | Product | Application and Cable Specification |

3901N | PVC insulating compound for VDE standard at 90℃ | Used for wires and cables which according with VDE standard |

3921N | PVC jacket compound for VDE standard at 90℃ | Used for wires and cables which according with VDE standard |

II. Productdescription

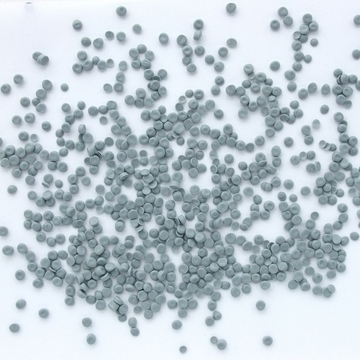

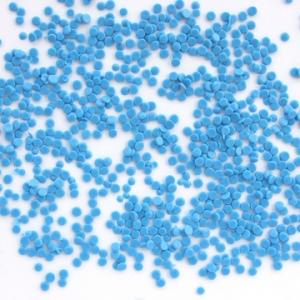

PVC compound for VDE standard wires andcables, based on PVC resin, is made into granula by mixing, plastification andgranulation with adding plasticizer, stabilizing agent, flame retardant andetc. The products meet various special requirements, such as differenthardness, UV stable, environment friend (RoHs, REACH, PAHs, chlorinated alkanesfree, phthalate free, and etc.),sub-shine and fog surface, low temperature resistant, PS/ABS transfer proof,rodent-repellent, termite-repellent, and transparent, and etc.

III. Processing

It is recommended that compound should beprocessed with common extruder having a minimum L/D ratio of 20.

The following temperature(℃)profile of extruder is recommended:

Zone | Zone 1 | Zone 2 | Zone 3 | Zone 4 | Head | Die |

Temperature ℃ | 140 | 160 | 170 | 175 | 180 | 175 |

IV. Storageand transport

Packaging:25kg/bag, PE membrane inside bag and Kraft outsidebag.

Storage and transport: Avoiding in directsunlight and weathering. The storage place should be in clean, cool, dry, andventilated conditions.

V. Properties

Table

Item | Unit | Standard Value | |||

3901N | 3921N | ||||

Tensile Strength | ≥ MPa | 16.0 | 10.0 | ||

Elongation at Break | ≥ % | 150 | 150 | ||

Impact Brittleness Temperature | ℃ | -15 | -20 | ||

Volume Resistivity, at 20℃ | ≥ Ω﹒m | 1.0×1011 | 1.0×108 | ||

Volume Resistance at working temperature of 90℃ | ≥ Ω﹒m | 1.0×108 | - | ||

Dielectric Strength | ≥ MV/m | 20 | 18 | ||

Hot Deformation | ≤ % | 30 | 50 | ||

Thermal Stability Time at 200℃ | ≥ min | 240 | 240 | ||

Thermal Aging |

|

|

|

|

|

Aging Temperature | ℃ | 135±2 | 115+2 | 135±2 | 115±2 |

Aging Time | h | 14×24 | 14×24 | 14×24 | 14×24 |

Tensile Strength after aging | ≥ MPa | 16.0 |

| 10.0 |

|

Variation on Tensile Strength | % | +25 |

| +25 |

|

Elongation at Break after aging | ≥ % | 150 |

| 150 |

|

Variation on Elongation at Break | % | +25 |

| +25 |

|

Loss of Mass after aging | ≤ g/m2 |

| 15 |

| 15 |

- Q: Can olive nets be used in combination with weed control methods?

- Yes, olive nets can be used in combination with weed control methods. Olive nets are primarily used to protect olive trees from birds and other animals that may damage the fruit. However, they can also act as a barrier to prevent weed growth around the trees. By properly securing the nets to the ground, they can effectively suppress weed growth and minimize the need for additional weed control methods such as herbicides or manual weeding.

- Q: What do you mean seven and five under the plastic cup?

- Therefore, when the bottle is used up, throw it away and stop using it as a cup. It is best to avoid the heat (as in a car or in the trunk), avoid cracks (release harmful substances); don't try to do storage containers of other items, so as not to cause health problems. "2" - HDPE (HDPE)

- Q: How do you know when it's the right time to install olive nets?

- The right time to install olive nets typically depends on the stage of olive tree growth and the ripening process. Olive nets are generally installed when the olives have reached their optimal size and color, but before they start falling off the tree due to natural ripening or external factors like wind or birds. Monitoring the olives closely and observing their maturity level is crucial to determine the appropriate time for installing olive nets.

- Q: What's the difference between cans and plastic bottles?

- Now the cans are coated with internal corrosion layer, is relatively safe, otherwise after the aluminum into the beverage will be adversely affected, aluminum intake too easy to have Alzheimer's disease on the human body; glass bottles generally safer, but be careful with.In contrast, cans are environmentally recyclable products, better than plastics.

- Q: What materials are olive nets made from?

- Olive nets are typically made from durable and lightweight materials such as high-density polyethylene (HDPE) or monofilament nylon.

- Q: Can olive nets be used for both manual and mechanical pruning?

- Yes, olive nets can be used for both manual and mechanical pruning. Olive nets serve as a protective barrier to catch the trimmed branches and leaves during pruning, whether it is done manually or with the help of mechanical tools.

- Q: Can olive nets be used for olive trees in regions with limited water availability?

- Yes, olive nets can be used for olive trees in regions with limited water availability. Olive nets are primarily used to catch falling olives during harvesting, but they can also serve as a protective covering for the trees. By covering the trees with nets, they can help reduce evaporation and water loss from the leaves, thus conserving water in regions with limited availability. Additionally, the nets can provide shade, which can further reduce water evaporation and help maintain soil moisture levels. However, it is important to note that using olive nets alone may not be sufficient to meet the water needs of olive trees in such regions, and other water-saving practices should also be considered.

- Q: What is the average cost of an olive net?

- The average cost of an olive net can vary depending on the size, material, and quality, but it typically ranges from $50 to $200.

- Q: Do olive nets damage the olive tree?

- No, olive nets do not damage the olive tree. They are used to protect the olives from birds and other animals, preventing loss or damage to the fruit. The nets are carefully placed over the tree branches and do not cause any harm or negative impact on the tree itself.

- Q: Do olive nets require any special training for installation?

- No, olive nets do not require any special training for installation. They are simple to set up and can be done by anyone following the instructions provided.

Send your message to us

PVC compound for VDE standard wires and cables

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 3000 Tons kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords