PVC insulating compound for automotive wires

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 3000 Tons kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PVC insulating compound for automotive wires

I. Type andapplication

Type | Product | Application and Cable Specification |

4701N | 70℃PVC insulating compound for automotive wires | Insulating compound for automotive wires which operation temperature of conductor is 70℃ |

4901N | 90℃PVC insulating compound for automotive wires | Insulating compound for automotive wires which operation temperature of conductor is 90℃ |

4051N | 105℃PVC insulating compound for thin wall automotive wires | Insulating compound for thin wall automotive wires which conductor section is less than 0.5 mm2, according with DIN72551 and JASO D611 standard |

4052N | 105℃PVC insulating compound for thin wall automotive wires | Insulating compound for thin wall automotive wires which conductor section is more than 0.5 mm2, according with DIN72551 and JASO D611 standard |

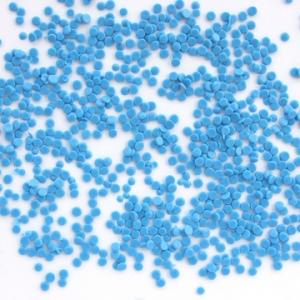

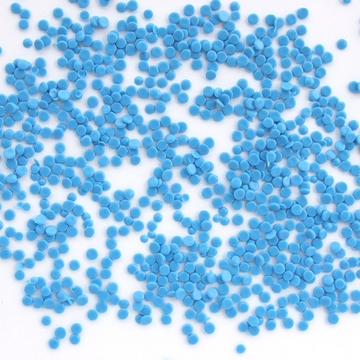

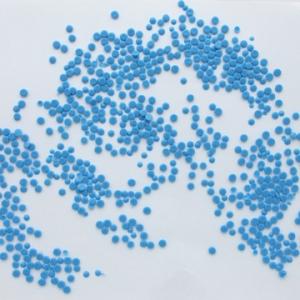

II. Productdescription

PVC insulatingcompound for automotive wires, based on PVC resin, is made into granula bymixing, plastification and granulation with adding plasticizer, stabilizingagent, flame retardant and etc. The products meet various specialrequirements, environment friend (RoHs, REACH, PAHs, chlorinated alkanesfree, phthalate free, and etc.), andetc.

III. Processing

It is recommended that compound should beprocessed with common extruder having a minimum L/D ratio of 20.

The following temperature(℃) profileof extruder is recommended:

Zone | Zone 1 | Zone 2 | Zone 3 | Zone 4 | Head | Die |

Temperature ℃ | 150 | 165 | 175 | 180 | 180 | 175 |

IV. Storageand transport

Packaging:25kg/bag, PEmembrane inside bag and Kraft outside bag.

Storage and transport: Avoiding in directsunlight and weathering. The storage place should be in clean, cool, dry, andventilated conditions.

V. Properties

Item | Unit | Standard Value | ||||

4701N | 4901N | 4051N | 4052N | |||

Tensile Strength | ≥ MPa | 16.0 | 16.0 | 16.0 | 16.0 | |

Elongation at Break | ≥ % | 150 | 150 | 150 | 150 | |

Impact Brittleness Temperature | ℃ | -15 | -15 | -15 | -15 | |

Volume Resistivity, at 20℃ | ≥Ω﹒m | 1.0×1011 | 1.0×1011 | 1.0×1011 | 1.0×1011 | |

Volume Resistance at working temperature | Temperature | ℃ | 70±1 | 90±1 | 95±1 | 95±1 |

Volume Resistance | ≥Ω﹒m | 1.0×108 | 1.0×108 | 1.0×108 | 1.0×108 | |

Dielectric Strength | ≥ MV/m | 20 | 20 | 25 | 25 | |

Hot Deformation | ≤ % | 40 | 40 | 30 | 30 | |

Thermal Stability Time at 200℃ | ≥ min | 60 | 60 | 100 | 100 | |

Thermal Aging |

|

|

|

|

| |

Aging Temperature | ℃ | 100±2 | 120±2 | 135±2 | 135±2 | |

Aging Time | h | 168 | 120 | 168 | 168 | |

Tensile Strength after aging | ≥ MPa | 16.0 | 16.0 | 16.0 | 16.0 | |

Variation on Tensile Strength | % | ±20 | ±20 | ±20 | ±20 | |

Elongation at Break after aging | ≥ % | 150 | 150 | 150 | 150 | |

Variation on Elongation at Break | % | ±20 | ±20 | ±20 | ±20 | |

Hardness | A | 92±2 | 92±2 | 95±2 | 92±2 | |

- Q: Do olive nets affect the ripening process of olives?

- Yes, olive nets can affect the ripening process of olives. The nets provide shade and protection to the olives, which can slow down the ripening process by reducing direct exposure to sunlight and air circulation. This can result in slower color change, softer texture, and delayed maturation. However, nets also shield the olives from birds and pests, preventing damage and ensuring a higher yield. Therefore, the impact of olive nets on ripening depends on the specific goals and priorities of the olive grower.

- Q: What are the parts of plastics and what are their characteristics?

- The so-called plastic, in fact, it is a kind of synthetic resin, the shape of the natural resin with pine resin similar to, through chemical means of artificial synthesis, and is called plastic.

- Q: Can olive nets be used in traditional olive groves?

- Yes, olive nets can be used in traditional olive groves. Olive nets are commonly used in traditional groves for harvesting olives as they help to collect the fallen fruits without causing damage to the trees or disrupting the natural growth pattern. They provide an efficient and convenient method for harvesting olives while maintaining the integrity of the traditional grove.

- Q: Do olive nets come with a warranty?

- Yes, olive nets typically come with a warranty.

- Q: Can olive nets be used for olive trees in regions with limited labor availability?

- Yes, olive nets can be used for olive trees in regions with limited labor availability. Olive nets are designed to capture the olives as they naturally fall from the trees during harvest, minimizing the need for manual labor to collect them. This makes them particularly useful in regions where there is a scarcity of labor resources. Olive nets can efficiently and effectively collect the olives, allowing farmers to harvest their crop with minimal manpower.

- Q: How do olive nets prevent bird droppings from contaminating olives?

- Olive nets prevent bird droppings from contaminating olives by creating a physical barrier between the birds and the fruit. The nets are spread over the trees, forming a protective layer that prevents birds from accessing the olives. This barrier effectively blocks the birds from perching or landing on the trees, thus minimizing the chances of droppings falling onto the olives.

- Q: How do olive nets prevent olives from falling to the ground?

- Olive nets are designed to act as a protective barrier, preventing olives from falling to the ground during harvest. These nets are spread out beneath the olive trees, creating a catchment area that catches the olives as they detach from the branches. By catching the olives before they hit the ground, the nets eliminate the risk of damage caused by impact, soil contamination, or loss due to pests or animals.

- Q: Can olive nets be used for olive trees in pots or containers?

- Yes, olive nets can be used for olive trees in pots or containers. Olive nets are typically used to catch falling olives during harvest, but they can also provide support to olive trees in pots or containers by preventing branches from drooping or breaking under the weight of the fruit.

- Q: Can olive nets be used in other fruit tree farming?

- Yes, olive nets can be used in other fruit tree farming. Olive nets are designed to protect the fruit from birds and other pests, and this functionality can be beneficial for other fruit trees as well. By covering the trees with olive nets, farmers can prevent birds from pecking at the fruit and reduce crop damage. Additionally, olive nets can also be used to collect fallen fruits during harvesting, making the process more efficient. Therefore, olive nets can be a versatile tool for fruit tree farming beyond just olives.

- Q: What are the advantages and disadvantages of plastics?

- The specific strength of plastic is much higher than that of cement concrete. It is close to or even beyond steel. It belongs to a kind of lightweight and high strength material.

Send your message to us

PVC insulating compound for automotive wires

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 3000 Tons kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords