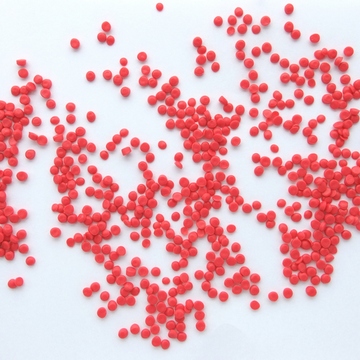

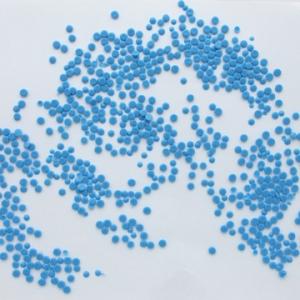

Flame retardant PVC insulating compound

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 3000 Tons kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Flame Retardant PVC Insulating Compound

I. Type andapplication

Type | Product | Application and Cable Specification |

7003N | 70℃Flame retardant PVC insulating compound | Flame retardant PVC insulating compound for cables and wires with temperature rating of conductorat 70℃ |

7302N | 70℃Flexible flame retardant PVC insulating compound | Flexible flame retardant PVC insulating compound for cables and wires with temperature rating of conductorat 70℃ |

9003N | 90℃ Flame retardant PVC insulating compound | Flame retardant PVC insulating compound for cables and wires with temperature rating of conductorat 90℃ |

1053N | 105℃Flame retardant PVC insulating compound | Flame retardant PVC insulating compound for cables and wires with temperature rating of conductorat 105℃ |

II. Productdescription

Flame retardant PVC insulating compound forwires and cables, based on PVC resin, is made into granula by mixing,plastification and granulation with adding plasticizer, stabilizing agent,flame retardant and etc. The products meet various special requirements, suchas different hardness, UV stable, environment friend (RoHs, REACH, PAHs,chlorinated alkanes free, phthalatefree, and etc.), sub-shine and fog surface, low temperature resistant, PS/ABStransfer proof, rodent-repellent, termite-repellent, and transparent, and etc.

III. Processing:

It is recommended that compound should beprocessed with common extruder having a minimum L/D ratio of 20.

The following temperature(℃) profile of extruder is recommended:

Zone | Zone 1 | Zone 2 | Zone 3 | Zone 4 | Head | Die |

Temperature ℃ | 140 | 160 | 170 | 175 | 180 | 175 |

IV. Storageand transport

Packaging:25kg/bag,PE membrane insidebag and Kraft outside bag.

Storage and transport: Avoiding in direct sunlightand weathering. The storage place should be in clean, cool, dry, and ventilatedconditions.

V. Properties

Table

Item | Unit | Standard Value | ||||

7003N | 7302N | 9003N | 1053N | |||

Tensile Strength | ≥ MPa | 15.0 | 15.0 | 16.0 | 16.0 | |

Elongation at Break | ≥ % | 150 | 180 | 150 | 150 | |

Impact Brittleness Temperature | ℃ | -15 | -20 | -15 | -15 | |

Volume Resistivity, at 20℃ | ≥Ω﹒m | 1.0×1011 | 1.0×1011 | 1.0×1011 | 1.0×1011 | |

Volume Resistance at working temperature | Temperature | ℃ | 70±1 | 70±1 | 90±1 | 95±1 |

Volume Resistance | ≥Ω﹒m | 1.0×108 | 1.0×108 | 1.0×108 | 5.0×107 | |

Dielectric Strength | ≥ MV/m | 20 | 20 | 20 | 20 | |

Hot Deformation | ≤ % | 40 | 50 | 40 | 30 | |

Thermal Stability Time at 200℃ | ≥ min | 60 | 60 | 80 | 80 | |

Oxygen Index | ≥% | 30 | 30 | 30 | 30 | |

Thermal Aging |

|

|

|

|

| |

Aging Temperature | ℃ | 100±2 | 100±2 | 100±2 | 135±2 | |

Aging Time | h | 168 | 168 | 240 | 168 | |

Tensile Strength after aging | ≥ MPa | 15.0 | 15.0 | 16.0 | 16.0 | |

Variation on Tensile Strength | % | ±20 | ±20 | ±20 | ±20 | |

Elongation at Break after aging | ≥ % | 150 | 180 | 150 | 150 | |

Variation on Elongation at Break | % | ±20 | ±20 | ±20 | ±20 | |

Loss of Mass | ≤ g/m2 | 20 | 20 | 15 | 23 | |

- Q: Can olive nets be used in conjunction with other farming practices?

- Yes, olive nets can be used in conjunction with other farming practices. Olive nets are commonly used in olive groves to catch the falling fruit during the harvesting season. This practice can be combined with other farming techniques such as pruning, irrigation, fertilization, and pest control to ensure optimal olive production. Additionally, olive nets can also be used to protect the trees from extreme weather conditions or bird damage. Overall, integrating olive nets with other farming practices can enhance productivity and protect the olive crop.

- Q: Can olive nets be used for both manual and mechanical pruning?

- Yes, olive nets can be used for both manual and mechanical pruning. Olive nets are versatile and can be used to collect the pruned branches and leaves during both manual and mechanical pruning processes.

- Q: Can the plastic lunch box be heated by microwave oven?

- No. 5 PP material: the only plastic box that can be put into the microwave oven. It can be reused after careful cleaning.

- Q: What kind of plastic bottles can be used again and again?

- Subsequently, the reporter found some food containing plastic bottle, was found in the bottom of the bottle is part of digital signs, such as China 550G installed at the bottom of honey bottle labeled "02". However, the reporter also found that many bottles at the bottom without any mark, like master 500ML fresh daily C Coca-Cola 450ML, beautiful fruit juice drink.

- Q: How do olive nets affect the yield of olives?

- Olive nets can significantly impact the yield of olives in a positive way. By placing nets underneath the olive trees, they prevent the olives from falling onto the ground, reducing the risk of damage and loss. The nets catch the olives as they ripen and fall, making it easier to collect them. This method also helps to keep the olives clean and free from dirt, debris, and pests. As a result, olive nets contribute to a higher yield of olives by maximizing the number of harvested fruits and maintaining their quality.

- Q: Do olive nets require any special installation techniques for sloped terrains?

- Yes, olive nets may require special installation techniques for sloped terrains. Sloped terrains can present challenges in ensuring proper coverage and stability of the nets. Techniques such as anchoring the nets with stakes or using additional support structures may be necessary to prevent sliding and maintain an effective barrier.

- Q: Can olive nets be used to improve water use efficiency?

- Yes, olive nets can be used to improve water use efficiency in olive groves. These nets are commonly used to reduce evaporation and protect the soil from direct sunlight, thus helping to conserve moisture and reduce water loss through evapotranspiration. By creating a microclimate that minimizes water requirements, olive nets can help optimize water use and improve overall water efficiency in olive cultivation.

- Q: Are there any specific colors of olive nets that are more effective?

- Yes, there are specific colors of olive nets that are more effective. The most commonly recommended color is black, as it blends well with the environment and provides better visibility for the olives. Additionally, black nets absorb more sunlight, helping to warm the olives and enhance their ripening process.

- Q: Can olive nets be used to reduce fruit drop?

- Yes, olive nets can be used to reduce fruit drop. These nets are commonly used in olive orchards to prevent the ripe fruits from falling to the ground prematurely. The nets create a physical barrier that catches the falling olives, allowing them to be harvested at their peak ripeness. By using olive nets, farmers can minimize fruit drop and maximize their yield.

- Q: What plastic sunscreen?

- Plastic products are exposed to sunlight or strong fluorescence, causing the aging of plastics due to the ability to absorb ultraviolet light. Adding light stabilizers can reduce the effect of UV light on plastics. Mainly used in PO products, mostly for PE, a few for PP, and PVC, ABS, PS, and so on.

Send your message to us

Flame retardant PVC insulating compound

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 3000 Tons kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords