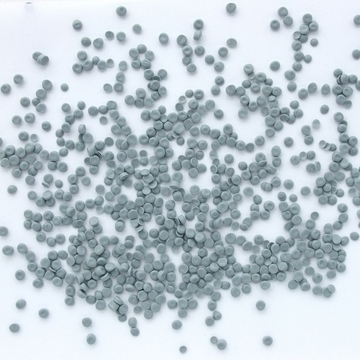

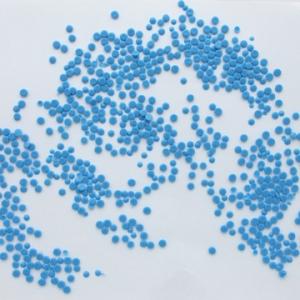

Flame retardant PVC jacket compound

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 3000 Tons kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Flame Retardant PVCJacket Compound

I. Type andapplication

Type | Product | Application and Cable Specification |

7023N | 70℃Flame retardant PVC jacket compound | Flame retardant PVC jacket compound for cables and wires with temperature rating of conductor at 70℃ |

7322N | 70℃Flexible flame retardant PVC jacket compound | Flexible flame retardant PVC jacket compound for cables and wires with temperature rating of conductor at 70℃ |

9023N | 90℃Flame retardant PVC jacket compound | Flame retardant PVC jacket compound for cables and wires with temperature rating of conductor at 90℃ |

0523N | 105℃Flame retardant PVC jacket compound | Flame retardant PVC jacket compound for cables and wires with temperature rating of conductor at 105℃ and heat resistant. |

II. Productdescription

Flame retardant PVC jacket compound forwires and cables, based on PVC resin, is made into granula by mixing,plastification and granulation with adding plasticizer, stabilizing agent,flame retardant and etc. The products meet various special requirements, suchas different hardness, UV stable, environment friend (RoHs, REACH, PAHs,chlorinated alkanes free, phthalatefree, and etc.), sub-shine and fog surface, low temperature resistant, PS/ABStransfer proof, rodent-repellent, termite-repellent, and transparent, and etc.

III. Processing:

Itis recommended that compound should be processed with common extruder having aminimum L/D ratio of 20.

Thefollowing temperature(℃) profileof extruder is recommended:

Zone | Zone 1 | Zone 2 | Zone 3 | Zone 4 | Head | Die |

Temperature ℃ | 140 | 160 | 170 | 175 | 180 | 175 |

IV. Storage andtransport

Packaging:25kg/bag,PE membrane insidebag and Kraft outside bag.

Storage and transport: Avoiding in direct sunlightand weathering. The storage place should be in clean, cool, dry, and ventilatedconditions.

V. Properties

Table

Item | Unit | Standard Value | |||

7023N | 7322N | 9023N | 0523N | ||

Tensile Strength | ≥MPa | 15.0 | 12.5 | 16.0 | 18.0 |

Elongation at Break | ≥ % | 180 | 200 | 180 | 250 |

Impact Brittleness Temperature | ℃ | -25 | -30 | -20 | -20 |

Volume Resistivity, at 20℃ | ≥Ω.m | 1.0×108 | 1.0×108 | 1.0×109 | 1.0×109 |

Dielectric Strength | ≥MV/m | 18 | 18 | 18 | 18 |

Hot Deformation | ≤ % | 50 | 65 | 40 | 40 |

Thermal Stability Time at 200℃ | ≥ min | 50 | 60 | 80 | 80 |

Oxygen Index | ≥ | 30 | 28 | 30 | 30 |

Thermal Aging |

|

|

|

|

|

Aging Temperature | ℃ | 100±2 | 100±2 | 100±2 | 135±2 |

Aging Time | h | 168 | 168 | 240 | 168 |

Tensile Strength after aging | ≥MPa | 15.0 | 12.5 | 16.0 | 18.0 |

Variation on Tensile Strength | % | ±20 | ±20 | ±20 | ±20 |

Elongation at Break after aging | ≥ % | 180 | 200 | 180 | 250 |

Variation on Elongation at Break | % | ±20 | ±20 | ±20 | ±20 |

Loss of Mass | ≤ g/m2 | 23 | 25 | 15 | - |

- Q: How does an olive net affect the labor required for harvesting?

- An olive net significantly reduces the labor required for harvesting by providing a convenient and efficient method to collect olives. Instead of manually picking olives from trees or using traditional methods like shaking or beating the branches, an olive net is spread around the base of the tree. When the olives are gently shaken or mechanically harvested, they fall onto the net, making it easy to collect them in large quantities. This eliminates the need for excessive bending, reaching, and climbing, thereby reducing physical strain and the number of workers needed for the task.

- Q: Can olive nets be used for olive tree pollination purposes?

- No, olive nets are not used for olive tree pollination purposes. Olive trees are typically wind-pollinated, and the use of nets is more commonly associated with harvesting olives to prevent them from falling to the ground.

- Q: How do olive nets help in reducing the risk of soil erosion?

- Olive nets help in reducing the risk of soil erosion by acting as a protective barrier over the soil. They prevent the impact of heavy raindrops from directly hitting the soil surface, which can dislodge and wash away the top layer of soil. Additionally, olive nets also trap any loose soil particles and prevent them from being carried away by wind or water. This helps to maintain the integrity of the soil structure and prevent erosion.

- Q: Can olive nets be custom-made?

- Yes, olive nets can be custom-made to meet specific size and shape requirements for various olive groves.

- Q: What are the characteristics of plastic products?

- Three indispensable synthetic materials in daily life. Specifically, the plastic is made of natural or synthetic resin as the main ingredient, adding various additives, in certain conditions such as temperature and pressure can be made into a certain shape, keep shape materials at room temperature.

- Q: How does an olive net affect the overall labor costs of harvesting?

- An olive net can significantly reduce the overall labor costs of harvesting. By using a net to catch the falling olives, it eliminates the need for manual picking, saving both time and labor. This mechanized approach allows for more efficient harvesting, reducing the number of workers required and lowering labor costs.

- Q: Can olive nets be used on olive trees grown in raised beds?

- Yes, olive nets can be used on olive trees grown in raised beds. The nets are designed to protect the olives from birds and other pests, and they can be easily draped over the trees in raised beds to provide this protection.

- Q: Do olive nets protect against birds?

- Yes, olive nets are designed to protect olive trees from birds by preventing them from accessing the fruit.

- Q: What are the main defects of common plastic products?

- Plastic products: mainly due to insufficient feeding, the melt filling flow is bad, too much inflation and bad exhaust causes to fill the cavity with plastic products shape incomplete or multi cavity individual cavity filled with.Dimensional instability: mainly due to poor strength of the die, poor precision, unstable injection molding machine and unstable forming conditions, the size of plastic products is unstable.Bubble: residual gas in plastic products due to melt inflated excessive or bad exhaust, and a small hole or clusters (note and vacuum bubble difference).Collapse (dent) or vacuum bubble: due to poor packing, poor cooling of plastic products, uneven wall thickness and high shrinkage of plastics.Flying too large: due to poor mold, the gap is too large, plastic flow is too good, too much feeding, plastic products along the edge of the thin thin wings.

- Q: How do you store olive nets when not in use?

- When not in use, olive nets can be stored by folding them neatly and placing them in a dry and cool area. It is important to ensure that the nets are clean and free from any debris before storing to prevent damage. Additionally, storing them in a compact and organized manner will help to prolong their lifespan and make them easily accessible for future use.

Send your message to us

Flame retardant PVC jacket compound

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 3000 Tons kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords