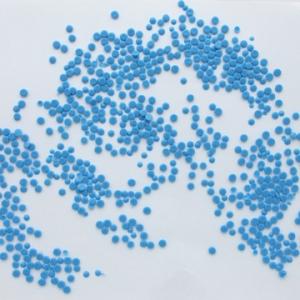

Oil resistant PVC jacket compound

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 3000 Tons kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Oil resistant PVCjacket compound

I. Type andapplication

Type | Product | Application and Cable Specification |

1372N | 70℃ Oil resistant PVC jacket compound | Jacket for oil resistant wires and cables which working voltage is 450/750V |

1392N | 90℃ Oil resistant PVC jacket compound | Jacket for oil resistant and heat resistant wires and cables which working voltage is 450/750V |

II. Productdescription

Oil resistant PVC jacket compound for wiresand cables, based on PVC resin, ismade into granula by mixing, plastification and granulation with addingplasticizer, stabilizing agent, anti-oxidant, butadiene-acrylonitrile rubber,pigment and etc.This product haswell performance of oil resistant. The products meetvarious special requirements, such as different hardness, UV stable,environment friend (RoHs, REACH, PAHs, chlorinated alkanes free, phthalate free, and etc.), sub-shine and fogsurface, low temperature resistant, PS/ABS transfer proof, rodent-repellent,termite-repellent, and etc.

III. Processing

It is recommended that compound should beprocessed with common extruder having a minimum L/D ratio of 20.

The following temperature(℃) profile of extruder is recommended

Zone | Zone 1 | Zone 2 | Zone 3 | Zone 4 | Head | Die |

Temperature ℃ | 140 | 160 | 165 | 170 | 170 | 170 |

IV. Storageand transport

Packaging:25kg/bag, PE membrane inside bag and Kraft outsidebag.

Storage and transport: Avoiding in directsunlight and weathering. The storage place should be in clean, cool, dry, andventilated conditions.

V. Properties

Table

Item | Unit | Standard Value | |

1372N | 1392N | ||

Tensile Strength | ≥ MPa | 12.5 | 12.0 |

Elongation at Break | ≥ % | 200 | 120 |

Impact Brittleness Temperature | ℃ | -40 | -20 |

Volume Resistivity, at 20℃ | ≥Ω﹒m | 1.0×108 | 1.0×108 |

Dielectric Strength | ≥ MV/m | 18 | 18 |

Thermal Stability Time at 200℃ | ≥ min | 50 | 80 |

Thermal Aging |

|

|

|

Aging Temperature | ℃ | 100±1 | 120±1 |

Aging Time | h | 168 | 120 |

Retention on Tensile Strength | ≥ % | 80 | 80 |

Retention on Elongation at Break | ≥ % | 70 | 70 |

Oil Resistant Test |

|

|

|

Test Temp. | ℃ | 90±2 | 90±2 |

Test Time | h | 24 | 24 |

Retention on Tensile Strength | ≥ % | 70 | 70 |

Retention on Elongation at Break | ≥ % | 70 | 70 |

- Q: Are olive nets safe for the environment?

- Yes, olive nets are generally considered safe for the environment. These nets are designed to protect olive trees from birds and other animals, preventing damage to the crop. They are made from biodegradable materials like natural fibers or plastic, which do not pose a significant threat to the environment. However, it is important to properly manage and dispose of these nets after use to minimize any potential negative impact.

- Q: Can olive nets be used for olive tree root protection?

- Yes, olive nets can be used for olive tree root protection. Olive nets are typically used to protect the fruit from birds and other animals, but they can also serve as a barrier to prevent damage to the roots of olive trees. The nets can be placed around the base of the tree, acting as a shield against potential harm caused by foot traffic, digging, or other disturbances.

- Q: Can olive nets be used on olive trees in different geographical locations?

- Yes, olive nets can be used on olive trees in different geographical locations. Olive nets are designed to protect the olives from birds and other animals, and to collect the fallen olives during harvest. They can be used in any region where olive trees are grown, regardless of the specific location.

- Q: Plastic products 2 can hold hot things?

- At present, many plastic products, with colorless and transparent special food bags of food is good, no other harm, opaque, or colored plastic bags are not packaged food, agricultural film is seemingly transparent, colored, is very light. It is not a packaged food product.

- Q: Can olive nets be used in both traditional and modern olive farming practices?

- Yes, olive nets can be used in both traditional and modern olive farming practices. Olive nets are versatile and can be used to protect the olives from birds and other pests, as well as to collect the olives during the harvest. They are commonly used in traditional farming methods where olives are hand-picked, as well as in modern practices where mechanized harvesting is employed. The use of olive nets helps to ensure a successful and efficient olive harvest regardless of the farming techniques employed.

- Q: Do olive nets come with a warranty?

- Yes, olive nets often come with a warranty.

- Q: Can olive nets be used in olive groves with limited water availability?

- Yes, olive nets can be used in olive groves with limited water availability. Olive nets are primarily used to collect the olives during the harvest season, and they do not directly affect the water requirements of the olive trees. However, it is important to note that ensuring proper irrigation and water management practices are in place is essential for the health and productivity of the olive trees, especially in areas with limited water availability.

- Q: How do olive nets impact the pruning process of olive trees?

- Olive nets have a significant impact on the pruning process of olive trees. These nets are used to protect the olives from damage during the harvesting process. By installing nets under the olive trees, the pruners can easily collect the fallen olives without worrying about causing any harm to the tree or the fruits. This allows for a more efficient pruning process as it eliminates the need for manual collection and reduces the risk of damaging the olives or the tree branches during the pruning. Overall, olive nets streamline the pruning process and ensure the safety of the harvested olives.

- Q: What does plastic melt mean?

- The melt flow rate instrument is a test facility for measuring the melt flow rate of thermoplastics under certain conditions. The melt flow rate is an index to measure the melt flow of plastics. The higher the value, the better the melt fluidity of the plastics.

- Q: What are the advantages and disadvantages of plastic wallpaper?

- Easy to paste, plastic wallpaper than other types of the wallpaper paste is more convenient, the plastic paper base wallpaper with the ordinary 107 adhesive agent or emulsion paste can turn white, not only has the advantages of simple construction and good air permeability, convenient replacement; plastic wallpaper wet state strength is also good, can be directly adhered to also not dry on the wall, also won't cause appeared, peeling of the drum.

Send your message to us

Oil resistant PVC jacket compound

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 3000 Tons kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords