Flame retardant PVC jacket compound for No.5 cable and soft optical cable

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 3000 Tons kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Flame retardant PVC jacket compound for 5#cable and soft optical cable

I. Typeand application

Type | Product | Application and Cable Specification |

2021N | 70℃ Flame retardant PVC jacket compound | Flame retardant PVC jacket compound special for 5# cables |

2023N | 70℃ Flame retardant PVC jacket compound | Flame retardant PVC jacket compound special for 5# cables, CM-class flame retardant |

II. Product description

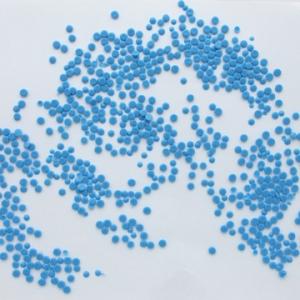

Flame retardant PVC jacket compound specialfor 5# cables, based on PVC resin, is made into granula by mixing,plastification and granulation with adding plasticizer, stabilizing agent,flame retardant and etc. The products meet various special requirements, suchas different hardness, UV stable, environment friend (RoHs, REACH, PAHs,chlorinated alkanes free, phthalatefree, and etc.), sub-shine and fog surface, low temperature resistant, PS/ABStransfer proof, rodent-repellent, termite-repellent, and transparent, and etc.

III. Processing

Itis recommended that compound should be processed with common extruder having aminimum L/D ratio of 20.

Thefollowing temperature(℃) profileof extruder is recommended:

Zone | Zone 1 | Zone 2 | Zone 3 | Zone 4 | Head | Die |

Temperature ℃ | 145 | 155 | 165 | 175 | 175 | 170 |

IV. Storageand transport

Packaging:25kg/bag, PEmembrane inside bag and Kraft outside bag.

Storage and transport: Avoiding in directsunlight and weathering. The storage place should be in clean, cool, dry, and ventilatedconditions.

V. Properties

Table

Item | Unit | Standard Value | |

2021N | 2023N | ||

Oxygen Index | ≥ | — | 32 |

Tensile Strength | ≥ MPa | 15.0 | 15.0 |

Elongation at Break | ≥ % | 180 | 180 |

Impact Brittleness Temperature | ℃ | -15 | -15 |

Volume Resistivity, at 20℃ | ≥Ω﹒m | 1.0×108 | 1.0×108 |

Dielectric Strength | ≥ MV/m | 18 | 18 |

Thermal Stability Time at 200℃ | ≥ min | 50 | 50 |

Hot Deformation | ≤ % | 50 | 50 |

Thermal Aging |

|

|

|

Aging Temperature | ℃ | 100±2 | 100±2 |

Aging Time | h | 168 | 168 |

Tensile Strength after aging | ≥ MPa | 15.0 | 15.0 |

Variation on Tensile Strength | % | ±20 | ±20 |

Elongation at Break after aging | ≥ % | 180 | 180 |

Variation on Elongation at Break | % | ±20 | ±20 |

Loss of Mass after aging | ≤ g/m2 | 23 | 23 |

- Q: How do olive nets help in reducing labor costs during harvesting?

- Olive nets help in reducing labor costs during harvesting by providing a more efficient and time-saving method. These nets are spread under the olive trees to catch the falling olives, eliminating the need for manual picking. Instead of manually collecting olives from the ground, laborers can simply gather the olives from the nets, significantly reducing the time and effort required. This efficient harvesting technique helps save labor costs by reducing the number of workers needed and increasing overall productivity.

- Q: What do you mean seven and five under the plastic cup?

- Transparent plastic bottles made from it are often called "plastic bottles". This plastic is heat-resistant to 70 degrees and is only suitable for warm drinks or cold drinks. If the high temperature liquid or heating, it is easy to deformation, there are harmful substances dissolved. And, scientists have found that after 10 months, the plastic could release carcinogens that are toxic to humans.

- Q: Do olive nets affect the overall appearance of the olive tree orchard?

- Yes, olive nets do affect the overall appearance of the olive tree orchard. The nets are used to protect the olives from pests and birds, but they also create a visual change in the orchard. The nets cover the trees and can alter their natural aesthetic, making the orchard look different compared to when the trees are uncovered.

- Q: Can I make tea with a plastic cup?

- There is from the sensory identification, see whether the plastic impurities, smell the taste is pungent. A good general can be used for the use of plastic entrance should be resistant to high temperature and low temperature (the specific standard I don't know), the general use of tea should be no problem, but now the credibility of the product is very low, even if the qualified product is not 100% reliable, so for their own health

- Q: Can olive nets be used for olive trees in subtropical regions?

- Yes, olive nets can be used for olive trees in subtropical regions. Olive nets are commonly used to protect the olives from birds, pests, and excessive sun exposure, regardless of the climatic conditions. They provide shade, prevent fruit damage, and ensure a better yield in subtropical regions as well.

- Q: What types of plastics do you have?

- Plastic refers to the organic synthetic resin as the main ingredient, added or not with other materials (additive) and artificial material. It is usually in the heat and pressure under the condition of plastic devices made with a certain shape. Plastic is a synthetic high molecular organic compounds with plasticity.

- Q: How do you understand the level of engineering plastics?

- 1, PET (polyethylene terephthalate): at present, the general mineral water, carbonated drinks and functional beverage bottles are used in this material. Heat resistant to 70 degrees, easy to deformation.

- Q: Do olive nets protect against birds?

- Yes, olive nets are designed to protect olive trees from birds by preventing them from accessing the fruit.

- Q: Can olive nets be used on trees with a tall height?

- Yes, olive nets can be used on trees with a tall height. Olive nets are designed to be draped over trees to catch falling olives during harvesting. They come in various sizes and can be adjusted to fit trees of different heights.

- Q: Are olive nets safe for wildlife?

- Yes, olive nets are generally safe for wildlife. These nets are designed to protect the olives from birds and other animals, while still allowing them to breathe and move freely. They are made of lightweight materials that do not harm wildlife or pose any significant risks to their well-being.

Send your message to us

Flame retardant PVC jacket compound for No.5 cable and soft optical cable

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 3000 Tons kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords