PVC jacket compound for UL stardard wires and cables

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 3000 Tons kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PVC jacket compound for ULstandard wires and cables

I. Type andapplication

Type | Product | Application and Cable Specification |

5621N | PVC jacket compound for UL standard at 60℃ | Used for wires and cables which according with UL standard, such as UL62, 83, 758, 1581 and etc. |

5821N | PVC jacket compound for UL standard at 80℃ | Used for wires and cables which according with UL standard, such as UL62, 83, 758, 1581 and etc. |

5921N | PVC jacket compound for UL standard at 90℃ | Used for wires and cables which according with UL standard, such as UL62, 83, 758, 1581 and etc. |

5521N | PVC jacket compound for UL standard at 105℃ | Used for wires and cables which according with UL standard, such as UL62, 83, 758, 1581 and etc. |

II. Product description

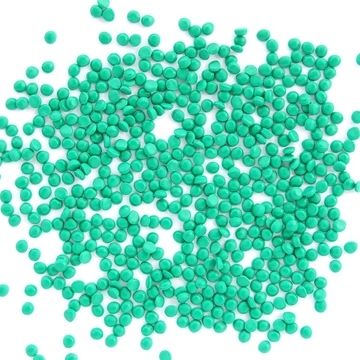

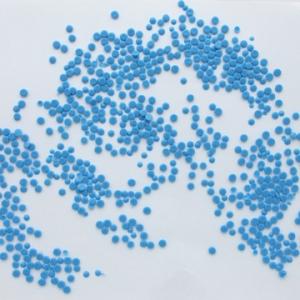

PVC jacket compound for UL standard wires and cables, based on PVCresin, is made into granula by mixing, plastification and granulation withadding plasticizer, stabilizing agent, flame retardant and etc. The productsmeet various special requirements, such as different hardness, UV stable,environment friend (RoHs, REACH, PAHs, chlorinated alkanes free, phthalate free, and etc.), sub-shine and fogsurface, low temperature resistant, PS/ABS transfer proof, rodent-repellent,termite-repellent, and transparent, and etc.

III. Processing:

It is recommended that compound should be processed with commonextruder having a minimum L/D ratio of 20.

The following temperature(℃) profileof extruder is recommended:

Zone | Zone 1 | Zone 2 | Zone 3 | Zone 4 | Head | Die |

Temperature ℃ | 140 | 160 | 170 | 175 | 175 | 175 |

IV. Storageand transport

Packaging:25kg/bag, PE membrane inside bag and Kraft outsidebag.

Storage and transport: Avoiding in direct sunlight and weathering.The storage place should be in clean, cool, dry, and ventilated conditions.

V. Properties

Table

Item | Unit | Standard Value | |||

5621N | 5821N | 5921N | 5521N | ||

Tensile Strength | ≥ MPa | 15.0 | 15.0 | 15.0 | 15.0 |

Elongation at Break | ≥ % | 150 | 150 | 150 | 150 |

Impact Brittleness Temperature | ℃ | -20 | -20 | -20 | -20 |

Volume Resistivity, at 20℃ | ≥ Ω﹒m | 1.0×109 | 1.0×109 | 1.0×109 | 1.0×109 |

Dielectric Strength | ≥ MV/m | 18 | 18 | 18 | 18 |

Hot Deformation | ≤ % | 50 | 50 | 50 | 50 |

Thermal Stability Time at 200℃ | ≥ min | 60 | 80 | 100 | 120 |

Thermal Aging (UL oven) |

|

|

|

|

|

Aging Temperature | ℃ | 100±1 | 100±1 | 121±1 | 136±1 |

Aging Time | h | 168 | 240 | 168 | 168 |

Retention on Tensile Strength | ≥ % | +85 | +70 | +85 | +85 |

Variation on Elongation at Break | ≥ % | +65 | +65 | +65 | +65 |

- Q: What is the most effective way to reduce the environmental pollution caused by plastic bags?

- White pollution is one of the plastic packages that are difficult to degrade. Disposable foam tableware such as fast and we used plastic bags and so on. It is very serious environmental pollution, buried in the soil is difficult to decompose, the soil will lead to reduced capacity, if the burning causes air pollution, so I do not advocate or less with it, buy the best own tools to reduce its use.

- Q: Do olive nets affect the water and nutrient uptake of olive trees?

- Yes, olive nets can have an impact on the water and nutrient uptake of olive trees. These nets are used to protect the olives from birds and other pests, but they can also create a barrier that affects the tree's ability to absorb water and nutrients from the soil. The nets reduce the amount of rainfall and irrigation water that reaches the tree's roots, and they can also limit access to sunlight, which is essential for photosynthesis and nutrient uptake. Therefore, it is important to monitor and manage the use of olive nets to ensure that they do not negatively impact the water and nutrient uptake of olive trees.

- Q: What sizes are olive nets available in?

- Olive nets are available in various sizes, ranging from small to large, depending on the specific needs and requirements of the olive grove.

- Q: Can olive nets be used for harvesting olives?

- Yes, olive nets can be used for harvesting olives. These nets are specifically designed to catch the falling olives during the harvesting process, making it easier to collect them and minimize damage to the fruit.

- Q: Can olive nets be used for olive trees in regions with high disease incidence?

- No, olive nets cannot effectively be used for olive trees in regions with high disease incidence. The nets may provide some protection against certain pests, but they do not offer sufficient protection against diseases. It is important to implement appropriate disease management strategies and treatments in such regions to safeguard the olive trees.

- Q: How do olive nets affect the development of olive tree roots?

- Olive nets can have a minimal impact on the development of olive tree roots. While the nets are primarily used to protect the olives from birds and other animals, they can also prevent adequate sunlight from reaching the lower branches and roots of the tree. However, this effect is typically temporary, as the nets are usually removed during the harvesting season, allowing the tree roots to regain access to sunlight and resume their normal growth.

- Q: Can olive nets be used on olive trees grown in vertical gardens?

- Yes, olive nets can be used on olive trees grown in vertical gardens. Olive nets are commonly used to protect the olive fruits from birds and other animals. Whether the olive tree is grown in a traditional orchard or a vertical garden, the nets can be installed to ensure the crop's protection.

- Q: Can olive nets be used in areas with limited rainfall?

- Yes, olive nets can be used in areas with limited rainfall. Olive nets are primarily used to protect olive trees from birds and other animals that may damage the crop. While they may not directly affect rainfall, olive nets can still be effective in areas with limited rainfall by preventing evaporation of water from the soil and reducing water stress on the trees. Additionally, olive trees are known for their ability to tolerate drought conditions, so they can still thrive in areas with limited rainfall even with the use of olive nets.

- Q: How to make plastic products soft?

- Heating, hot water, hot air can be generally around seventy degrees began to soft

- Q: Do olive nets affect the appearance of olive trees?

- Yes, olive nets can affect the appearance of olive trees. When olive nets are placed over the trees to collect the olives during the harvesting season, they can change the overall look of the tree by covering its branches and obscuring the natural shape and foliage.

Send your message to us

PVC jacket compound for UL stardard wires and cables

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 3000 Tons kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords