PVC compound for AS standard wires and cables

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 3000 Tons kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PVC compound for AS standard wires and cables

I. Type andapplication

Type | Product | Application and Cable Specification |

V-90 | 90℃ PVC insulating compound | According with V-90、standard of AS/NZS 3808:2004 |

5V-90 | 90℃ PVC jacket compound | According with 5V-90 standard of AS/NZS 3808:2004 |

II. Product description

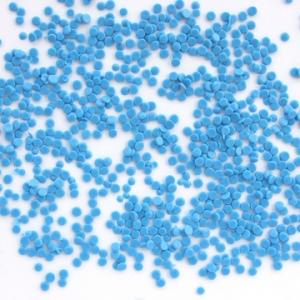

PVC compound for AS standard wires andcables, based on PVC resin, is made into granula by mixing, plastification andgranulation with adding plasticizer, stabilizing agent, flame retardant andetc. The products meet various special requirements, such as differenthardness, UV stable, environment friend (RoHs, REACH, PAHs, chlorinated alkanesfree, phthalate free, and etc.),sub-shine and fog surface, low temperature resistant, PS/ABS transfer proof,rodent-repellent, termite-repellent, and transparent, and etc.

III. Processing

It is recommended that compound should beprocessed with common extruder having a minimum L/D ratio of 20.

The following temperature(℃) profile of extruder is recommended

Zone | Zone 1 | Zone 2 | Zone 3 | Zone 4 | Head | Die |

Temperature ℃ | 140 | 165 | 170 | 175 | 175 | 175 |

IV. Storage and transport

Packaging:25kg/bag, PE membrane inside bag and Kraft outsidebag.

Storage and transport: Avoiding in directsunlight and weathering. The storage place should be in clean, cool, dry, andventilated conditions.

V. Properties

Table

Item | Unit | Standard Value | |

V-90 | 5V-90 | ||

Tensile Strength | ≥ MPa | 12.5 | 12.5 |

Elongation at Break | ≥ % | 150 | 150 |

Impact Brittleness Temperature | ℃ | -15 | - |

Volume Resistivity, at 20℃ | ≥Ω﹒m | 4.0×1010 | - |

Volume Resistivity, at 90℃ | ≥Ω﹒m | 2.0×106 | - |

Dielectric Strength | ≥ MV/m | 20 | 18 |

Hot Deformation | ≤ % | 50 | 50 |

Thermal Stability Time at 200℃ | ≥ min | - | - |

Thermal Aging |

|

|

|

Aging Temperature | ℃ | 115±2 | 115±2 |

Aging Time | h | 504 | 504 |

Tensile Strength after aging | ≥ MPa | - | - |

Retention on Tensile Strength | % | +75 | +75 |

Elongation at Break after aging | ≥ % | - | - |

Retention on Elongation at Break | % | +65 | +65 |

Loss of Mass | ≤ mg/cm2 | 2.5 | 2.5 |

- Q: Can olive nets be used on olive trees grown in humid regions?

- Yes, olive nets can be used on olive trees grown in humid regions. Olive nets are commonly used to protect the olives from pests, birds, or excessive sun exposure. While humid regions may have higher disease and pest pressure, proper netting can still be effective in reducing damage and ensuring a successful harvest.

- Q: How do olive nets help in reducing the risk of soil erosion?

- Olive nets help in reducing the risk of soil erosion by acting as a protective barrier over the soil. They prevent the impact of heavy raindrops from directly hitting the soil surface, which can dislodge and wash away the top layer of soil. Additionally, olive nets also trap any loose soil particles and prevent them from being carried away by wind or water. This helps to maintain the integrity of the soil structure and prevent erosion.

- Q: Can olive nets be used for both mechanical and hand harvesting?

- Yes, olive nets can be used for both mechanical and hand harvesting. The nets are widely utilized in olive groves to collect the falling olives during mechanical harvesting methods, such as shaking or sweeping the trees. Additionally, they can also be beneficial for hand harvesting by placing them under the trees to catch any olives that are manually picked or gently knocked off the branches.

- Q: Can olive nets be customized for specific orchard requirements?

- Yes, olive nets can be customized for specific orchard requirements.

- Q: What types of plastics do you have?

- According to the molecular structure and thermal properties of synthetic resins in plastics, plastics can be divided into two types, thermoplastics and thermosetting plastics.(1) the characteristics of thermoplastics1) the resin molecules are linear or branched.2) softening when heating, when reaching a certain temperature, melting state, become a flow of viscous fluid, under certain pressure can be shaped into a certain shape, after cooling can maintain the shape has been formed. If heated again, it can be softened, melted and formed again and again.3) in the process of heating and cooling, it is mainly physical change, and in a few cases there are chemical changes.

- Q: How do olive nets affect the yield of an olive grove?

- Olive nets significantly affect the yield of an olive grove by providing protection against birds, reducing fruit loss due to predation. The nets act as a barrier, preventing birds from accessing the olives, which helps to preserve a higher percentage of the crop. Additionally, olive nets also aid in controlling sunburn damage on the fruits, resulting in a higher quality yield. Overall, the use of olive nets positively impacts the yield and productivity of an olive grove.

- Q: Do plastic products contain toxic substances?

- Can not say both, more in favor of ystm's statement.Some plastic products are non-toxic, such as water cups, etc., but some plastic products are poisonous, for example, plastic bags will not be solved.Still have specific plastic concrete analysis, is.I work in Tai'an modern plastics Co., Ltd., mainly providing plastic geogrid and other materials

- Q: Can olive nets be used on olive trees grown in raised beds?

- Yes, olive nets can be used on olive trees grown in raised beds. Olive nets are commonly used to protect the tree's fruit from birds and other animals, regardless of whether the trees are grown in raised beds or in the ground. They provide a physical barrier that prevents pests from accessing the fruit, ensuring a higher yield and better quality harvest.

- Q: How do olive nets prevent olives from being damaged by rain?

- Olive nets prevent olives from being damaged by rain by creating a protective barrier that shields the fruit from the impact of water droplets. The nets are placed over the olive trees, forming a canopy-like structure that keeps the rainwater from directly hitting the olives. This helps to prevent bruising, splitting, and waterlogging, which can compromise the quality and yield of the olives. Additionally, the nets also act as a shield against hail and other adverse weather conditions, providing further protection to the fruit.

- Q: How do olive nets prevent olives from being pecked by birds?

- Olive nets are designed to physically cover the olive trees, forming a barrier that prevents birds from accessing the fruit. This prevents the birds from pecking or damaging the olives, ensuring a higher yield and better quality harvest.

Send your message to us

PVC compound for AS standard wires and cables

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 3000 Tons kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords